Ⅰ. Introduction

Cuivre granulators are professional equipment specially designed to recycle waste cables. It can crush waste cables into small particles of 3~5mm and then separate the most valuable metal resource from them – copper.

1. Copper granulators — a wide range of applications

They can reduce the pollution of waste metals to the environment, realize the recycling and reuse of copper resources, and effectively protect the environment. By quickly processing waste cables into bright and clean pure copper granules and plastic particles, they can also increase the production efficiency of recyclers to a new level, and improve the quality of recycled copper, bringing ideal economic benefits to recyclers. Therefore, it is the perfect equipment for major metal recycling centers, scrap car recycling stations, scrap yards, garbage stations, etc.

2. USA copper market’s current situation

The United States is the second largest copper consumer in the world. Copper is a major contributor to the U.S. economy and plays an irreplaceable role in many fields such as electricity, transportation, construction, and energy. Since copper can be reused many times without any performance loss, it is an ideal metal resource with high recycling value. Recycling copper is a win-win situation for both society and recyclers: not only meets a large part of society’s demand for copper but also brings considerable income to recyclers.

In 2023, the U.S. Department of Energy officially included copper in the list of critical materials. According to their forecast, the demand for copper will continue to rise in the next decade and will double by 2035. This shows that recycled copper will occupy an increasingly important position in the supply of copper. In this context, as the most advanced technology for recycling copper on the market, copper granulators will play a vital role in the copper recycling field with their ultra-high efficiency and high quality of recycled copper.

Ⅱ. Copper granulator market forecast

How will the copper granulators market develop in the future? Can recyclers find sufficient sources of waste cables? Is there a broad sales market for recycled copper? Will copper prices rise or fall? What progress will copper granulator technology make?

This chapter will predict the future development trend of the copper granulators market in detail to help you judge whether the profits brought by copper granulators can meet your expectations.

1. Rich sources of waste cables

Copper, the world’s third most widely used metal, plays a vital role in various industries, especially in the electrical field. Copper’s unique conductivity and durability make it an irreplaceable material in the electrical field. Nowadays, the application of electricity covers almost every corner of the world, so there are a huge number of waste cables all over the world, providing copper recyclers with a reliable and abundant source of raw materials, and ensuring the stability of the copper recycling business.

2. Huge demand for recycled copper

Looking into the future, with the development of electricity, automobiles, and other fields, the world’s demand for copper will continue to grow. Copper will be in short supply, and mining new copper mines alone cannot meet the huge market demand, which shows the importance of recycling copper. Recycling copper will become a great important part of the copper supply, providing a wide sales market for recyclers. Therefore, investing in copper granulators will follow the trend of the times and enable recyclers to meet the needs of the environment and the market.

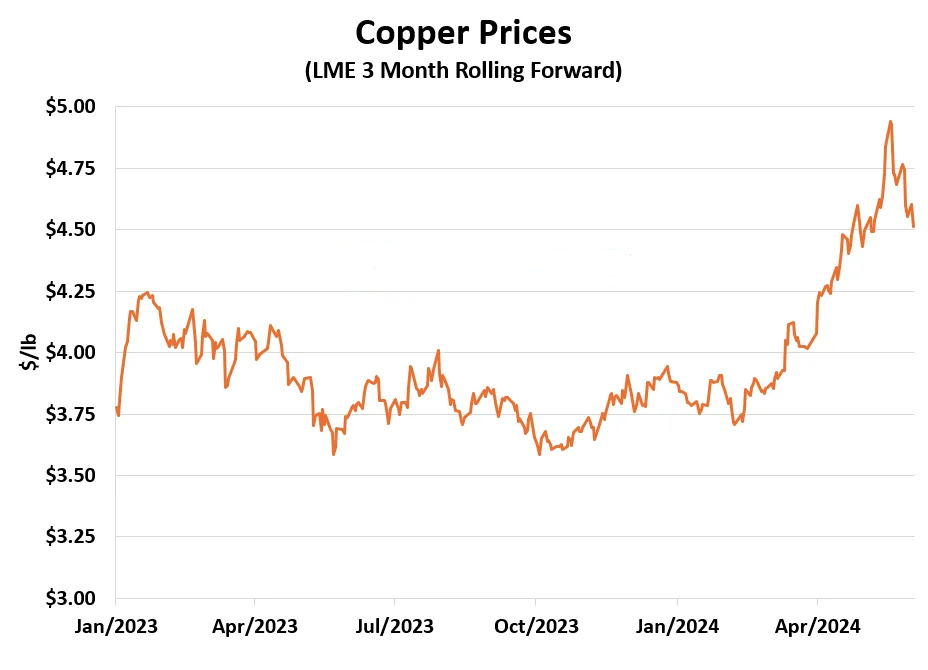

3. Steady growth in copper prices

Copper price is an important factor affecting the profit of copper recycling. After investigation, we found that copper prices have been rising almost all the time in the past decade. In 2015, the price of copper ranged from about $2.5 per pound to $2.8 per pound, and as of July 2024, the price of copper has reached $4.5 per pound, with a growth rate of 70%. Although there have been some declines during this period, the overall trend is rising. Since copper will be in short supply in the future, we believe that copper prices will continue to rise in the next few years, bringing ideal profits to copper recyclers.

4. Technological progress of copper granulators

In the United States, labor costs are very high. Therefore, we believe that copper granulators will pursue higher efficiency and more automated production in the future to ensure that recyclers can obtain higher profits while minimizing labor costs. Moreover, the United States has extremely high standards and requirements for environmental protection. In the future, copper granulators will develop in a more environmentally friendly and zero-pollution direction to comply with government regulations.

5. The rise of emerging markets

In addition to the United States, emerging markets in the global copper recycling industry are also rising rapidly. In Asian countries, especially in China and India, as people pay increasing attention to metal resource protection and sustainable development, more and more recyclers are entering the copper recycling industry. Europe and Latin America are also rapidly expanding their copper recycling work in line with their government policies and environmental regulations. As copper recycling work in these regions expands, copper granulators will become an important tool for them to improve production efficiency.

IN SUMMARY, recycled copper has abundant raw material sources, a wide sales market, and ideal economic benefits. In the future, copper granulator technology will also conform to the mainstream of sustainable development and develop more efficiently, automatically, and environmentally friendly. At the same time, there are emerging markets joining the copper recycling industry. It can be said that the copper granulators market has great development potential.

Ⅲ. Prediction of the TOP 6 best-selling copper granulator models in the United States in 2025

To help recyclers improve their production efficiency and competitiveness in the market, we have compiled the 6 copper granulators that are most likely to be hot-selling in the United States in 2025. They have their own characteristics and advantages, and can provide strong support for recyclers in different situations. Enhance your recycling capability with these 6 powerful copper granulators, and they will help you quickly occupy the market.

1. BS-F3000 copper granulator machine

BS-F3000 represents the highest efficiency level of copper granulators on the market and is the best choice for major recycling companies.

BS-F3000 copper granulator is a standard model with the largest processing capacity and the most complete accessories among BSGH Granulator’s copper granulators, capable of processing 1200~1500kg of cables per hour. The powerful functions support it not only processing almost all kinds of waste cables with a diameter of less than 25mm but also waste radiators.

Components:

- a double-axis pre-shredder

- a main crusher

- 2 air separators

- 4 vibrating screens

- 2 electrostatic separators

- 2 magnetic separators

- 2 dust collection devices

- BS-F3000=ECO1000+Preshredder+2 Electrostatic separator

- BS-F3000 is the most popular in USA market.

2. BS-ECO1000 copper granulator machine

ECO1000 has been on the best-selling list in the United States for several consecutive years, so we infer that it will continue its past glory.

ECO1000 copper granulator is the main body of BS-F3000, It is also the perfect solution for efficient recycling of various waste cables, with a processing capacity of up to 1000 kg/heure. The same top quality as BS-F3000 and the competitive price make it the most cost-effective model among large copper granulators.

Components:

- a main crusher

- 2 air separators

- 4 vibrating screens

- 2 dust collection devices.

3. BS-N130 copper granulator Machine

Compared with BS-F3000 copper granulator and ECO1000 copper granulator, BS-N130 copper granulator has a smaller processing capacity and can process 400~700kg of waste cables per hour. The sturdy structure makes it unnecessary to maintain and replace parts frequently.

The low energy consumption design makes it more energy-efficient than 90% of similar machines on the market. The simple operation method and fully automatic recycling process can save a lot of labor costs. These features make BS-N130 the first choice for many customers to save costs.

Components:

- One Pre-shredder

- One main crusher

- 1 air separator system

- Copper outlet and plastic outlet vibration table

- BS-N130=BS-N125+Pre-shredder

- This model is 2nd popular in USA market.

4. BS-N125 Copper granulator machine

BS-N125 copper granulator is the main body of BS-N130. It is the best-selling medium-sized copper wire recycling machine of BSGH Granulator, with a processing capacity of 300~500KG. If you don’t have so many waste cables now, but consider that the recycling business may expand in the future, BS-N125 will be your best choice. When your recycling business expands, you can directly add a pre-shredder to your BS-N125 to expand its capacity without changing to a model with a larger processing capacity, which is very convenient.

Components:

- a main crusher

- an air separator

- 2 vibrating tables

- a dust collection device

5. BS-D20 copper granulator machine

In view of the good development prospects of the copper market in 2025, we believe that more people will join the copper recycling field, so small copper granulator machines will also have the potential to be hot-selling.

BS-D20 copper granulator is a small copper granulator machine with a processing capacity of 200 kg/heure. Although BS-D20 is a small machine, it also has high quality and long service life that can compete with European brand machines, making it one of the most likely models to be hot-selling in the United States in 2025.

Components:

- a main crusher

- an air separator

- a dust collection device

- a vibrating screen

6. BS-D75 Copper Granulator Machine

Since the BS-D75 copperappeared, it has been one of the best-selling machines of BSGH Granulator and is the first choice for most customers to start their recycling business. Therefore, we have reason to believe that BS-D75 will continue to sell well in 2025.

The BS-D75 copper granulator is the smallest three-phase model, capable of processing 75kg of waste cable per hour. The BS-D75 is small and cheap, making it ideal for recyclers who are just entering the copper recycling industry and do not have a stable source of waste cable.

Components:

- a main shredder

- an air separator

- a dust collection device

- a vibrating screen

The challenge we faced in the future:

With advancements in technology, BSGH Granulator copper granulators have become increasingly efficient and reliable, offering better performance than ever before than other granulators in the market, our machines also can compete with Euro granulators, and maybe exceed theirs. As demand for recycled copper grows, granulators will need to be easier to operate, with intuitive controls and automated processes that minimize manual intervention, in future granulator manufacturers will need to focus on creating machines that not only handle larger volumes of material but also consume less power, reduce downtime, and require less maintenance. Balancing high performance with operational simplicity will be key to overcoming the technical challenges in the copper recycling industry.

Ⅴ. Conclusion

After detailed investigation and analysis, we believe that copper granulators have great development potential in the US market by 2025. It has sufficient raw materials, a wide sales market, and huge profits. In addition, we also believe that there are 6 copper granulators that will be hot-selling in the US next year. By improving production efficiency and reducing costs, they can help recyclers of all sizes make money quickly.