For High-end Market and High Standard Requests Customers

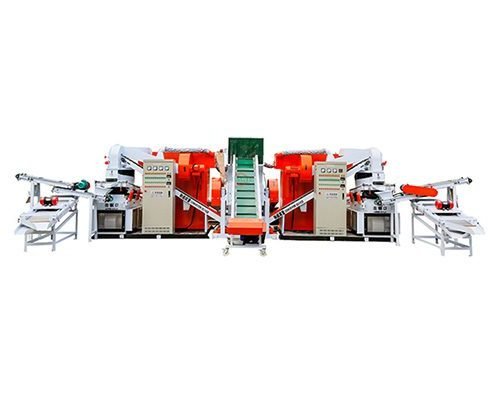

High-end N Series Cable Granulators Machine

- Low copper loss

- Professional R&D

- 70% of china market at least

What IS N Series Cable Granulator machine

The N series cable granulators machines are mainly for recycling all kinds of scrap wires and cables, which is a new high-end series product launched by Granulateur BSGH. And N series cable granulators machines are specialized for crushing scrap cables into mixed granules and then separating copper from plastic.

Our cable granulators machines can rival the quality of Euro machines, we can promise the recycling effect and long service life. I believe you will be amazed by its excellent processing effect after using it, and then find that it is worth the investment.

Case Video Of Our Cable Granulator Machine

Some customers want to know the effect of processing different cables, therefore, we have shot some feedback and testing videos of processing different cable materials. You can see the video below and check the machine’s performance. Then you will know why our N series cable granulators hot sell all over the world.

Liste de lecture

Advantages of Cable Granultors Machine

obtenir deux fois plus de résultats avec la moitié des efforts

Efficient processing

N series cable granulators machines can quickly process a large amount of scrap wires and cables, saving labor and time costs and improving processing efficiency. At the same time, the blades of our N series cable granulators machines are made of skd-11 material, which enables it to efficiently process scrap wires and cables.

High economic benefits

The copper resources in scrap wires and cables have high economic value. The use of N series cable granulators machines can efficiently recycle copper in scrap wires, thereby obtaining more economic benefits. Meanwhile, the high processing efficiency and low labor cost of the cable granulators machines also bring significant economic benefits.

High recovery rate

Using cutting-edge processing technology, the N series cable granulators machines can completely separate the copper from scrap wires and cables, thereby maximizing the recovery and reuse of copper resources in scrap wires, while also effectively reducing the pollution caused by waste plastics to the environment.

Easy operation and maintenance

With an intelligent control system, the N series cable granulators machines are simple and safe to operate. Usually one person can complete the entire process, which reduces the difficulty of operation. In addition, the N series cable granulators machines have a simple structure, exquisite appearance, and are easy to replace the blades and sieve meshes, which also simplifies maintenance work to a certain extent.

Contactez-nous

N series cable granulator machines are the best in China, specialized for splitting and crushing cables into mixed granules and then separating copper from plastics.

If you want our machine to help you make money as soon as possible, please contact our sales staff directly, they will provide you with professional solutions

Onpage Category

Website Category

N Series Cable Granulators Machine List

Our N series cable granulators machines are as follows:

Structure of Cable Granultors Machine

(Take BS-N130 as an example)

The main structure of N series cable granulators machines are below:

It is used for transporting scrap cables, so it can simplify the manual operation process and improve the recycling efficiency.

For crushing the cables, the scrap cables will be processed into small particles by these two machines.

Collect dust produced throughout the recycling process.

It is used for the separation purpose, mixed copper-plastic particles can be separated by adjusting air flow and vibration frequency.

Our company has designed Double-layer magnetic separator and strong magnetic separator.

Double-layer magnetic separator is installed before the copper outlet, strong magnetic separator is installed behind pre-shredder. Both of them all can remove the iron in copper, improving the purity of copper granules and protecting crusher’s blades.

Optional accessories for N series

The cable granulators machine is composed of many different parts and can also be assembled with various optional components. The following is main optional parts

Broyeur à double arbre

Dual shaft shredder is a type of industrial shredding machine, which is designed to effectively shred various materials into small pieces. This machine is equipped with two parallel shafts which rotate in opposite directions and blades installed on them, intermeshing to achieve material shredding process.

Because of their robustness, versatility and high shredding capacity, dual shaft shredder suitable for shredding a wide range of materials, including but not limited to plastic, wood, paper, metal and so on.

In scrap cable recycling field, it usually cooperates with cable granulators machine. After processing by dual shaft shredder, raw materials will be crushed into 5-10CM pcs, which can improve recycling efficiency and protect the main crusher blades. Crushed cables and wires are easier to be crushed by main crusher.

- Big Power: 22KW with Enlarged Reduction Gearbox, Capable for 3sets Machines Raw Material Crushing

- Small Size Easy To Move

- Low Noise

- PLC Control System And Automatic Control

| Taille | L2200*W950*H1450MM |

|---|---|

| Poids | 1435KG |

| Volume | 3.03M³ |

| Pouvoir | 22KW |

| Tension | 380V,50HZ, or Customized |

Séparateur magnétique

Magnetic separators are used to remove the iron from scrap cables. We have two types of magnetic separators in our N series cable granulators machine.

- Higherseparating rate and efficiency

- High-quality and 1-year warranty

- Small size and easy to operate

Installed on the copper outlet, it is mainly used for removing iron in copper granules.

| Surface Magnetism | About 800 Gauss |

|---|---|

| Poids | 165KG |

| Tension | 300~800KG/H |

| Pouvoir | 0.75KW |

| Taille | 2100*550*1550MM |

Installed on convey belt behind the dual-shaft shredder, it is mainly used for removing the ferrous cable pieces.

Capacité | 300-800KG/H |

Pouvoir | 0.75KW |

Poids | 165KG |

Taille | 2100*550*1550MM |

Surface Magnetism | About 3000 Gauss |

Séparateur électrostatique

An electrostatic separator is specially designed for people who pursue higher recycling rate or have capillary wires, it is installed at the plastic outlet and process the plastic granules again. N series granulators machine mainly has 2 models of electrostatic separators for you to choose:

Roller Diameter | 320mm |

Roller Length | 1000mm |

High Voltage | 0-60KV |

Pouvoir | 8KW |

Capacité | 100-150KG/H |

Taille | 1750*1380*3500 MM |

| Roller Diameter | 320MM |

|---|---|

| Roller Length | 1000MM |

| High Voltage | 0~60KV |

| Pouvoir | 8KW |

| Capacité | 100~150KG/H |

| Taille | 1750*1380*3500MM |

Convey Belt

In order to save your energy and time, you can equip a conveyor belt before pre-shredder.

| Poids | G.W.: 210KG |

|---|---|

| Taille | L2880*W820*H2100 |

| Tension | 380V 50HZ 3-Phase Power |

In order to transport crushed pieces from pre-shredder to main crusher quickly for further processing, there has one big conveyor belt.

| Poids | G.W.: 210KG |

|---|---|

| Taille | L3830*W900*H2350 |

| Tension | 380V 50HZ 3-Phase Power |

Cable Granulator machine Wearing Parts

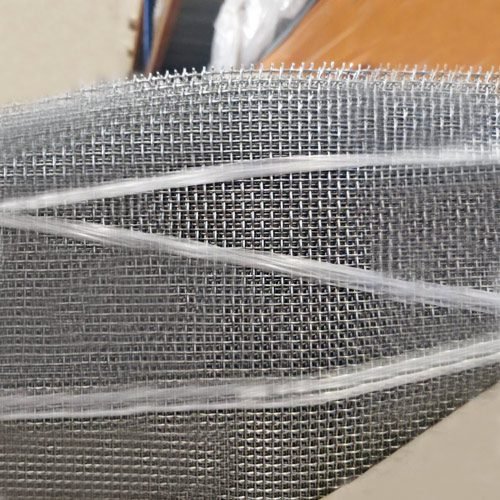

N Series Blades

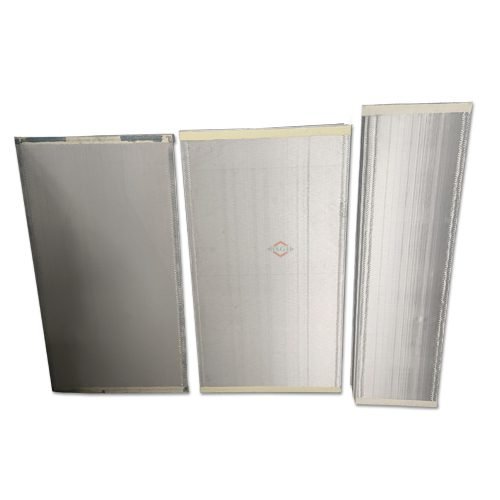

N Series Cruhser Sieve

N Series Air Separator Sieve

N Series Small Vibrating Sieve

Cable Granulator for sale - Why Choose Our N series?

Big capacity, high recycling rate, easy to operate, multi-choice, having good market reaction all around the world.

- One company really has more than 25 years of experience in production and technical.

- Standard configurations have multiple choice for you to choose from;

- For different districts, different countries have different 3-phase power supplies: 220V, 380V, 415V, 440V, 480V and etc.

- Real worry-free after-sales service: prompt, on time, in time, professionally.

for whom?

- Have big quantity of scrap cables.

- Want a really good quality machine.

- Want to liberate from complex routine repairs.

- Requires low copper loss.

most advanced technology

Easy to operate: even a new beginner can use the machine well.

Don’t need to change the blades and adjust the machine frequently, which can save you costs.

You won’t encounter a situation where the machine still doesn’t work properly no matter how you adjust it.

By the way, if you need a small capacity ou medium capacity machine or a higher cost-effective machine, I recommend you our Série D.

Profit analysis for BSGHGranulator High-End cable granulators

Take BS-N130 As Example

Many customers don’t know how to calculate the profit of recycling copper wire, how much we can earn for dismantling copper wire recycling? now I’ll list the cost samples, which you can do according to your actual situation.

| Coût de fonctionnement par jour ($) | ||||

|---|---|---|---|---|

| Saisir | Câbles de voiture usagés | Consommation d'énergie | Ouvriers | |

| Quantité | 4.8 T | 67KW/H*8H=536KW | 2 ouvriers | |

| Prix unitaire | 4691/T | 0.14 | 21,42/jour | |

| Coût d'entrée | 22516.8 | 75.04 | 42.84 | |

| Coût total | 22634.68 | |||

| Revenu par jour ($) | ||||

|---|---|---|---|---|

| Sortir | Cuivre | Plastique | ||

| Quantité | 4.8*55%=2.64 | 2.16 | ||

| Prix | 10008/T | 300/T | ||

| Revenu | 26421.12 | 648 | ||

| Revenu total | 27069.12 | |||

Bénéfice quotidien= Daily Income – Daily Outcome = 27069.12 – 22634.68 = 4434.44 ($)

The above data is according to our customer’s data provided, due to different countries’ situation not same, so above data is just for reference.

how customer comments about our Cable Granulator

Customer satisfaction is the most convincing evidence of machine quality. Nothing makes us prouder than the more money our customers can make with our machines. The comments below are using feelings of our regular customers:

FAQ

We prepare the questions you may worry about and showed the response solutions below.

For machine maintenance, I suggest you can check the crusher blades per month. If you find that the cables can't be crushed well, you can use sharpener to sharpen the blades.

Furthermore, using a vacuum cleaner to clean the crusher sieve mesh, air separation sieve mesh and vibrating table sieve mesh regularly for best performance and high efficiency, all this maintenance is very easy, and our staff will send you video link for your reference.

If you have a few plug cables, our machine can process well, no worries.

If you have many plug cables, we professionally suggest you remove them first, it will be better for blades; if you don't want to remove them in advance, it's also okay, but maybe you need to sharpen the blades frequently.

- We have more than 25 years of experience in copper recycling fields.

- We have a professional technical team, before machines shipping out, we will test them at least 5 times, make sure everything is well.

- Our machines are made of high-quality steel, the machine weight is much higher than other machines on the market, and our blades are made of skd-11 material, which is tough and wear-resistant, allowing you to use it without worry.

- We provide one-year warranty and whole-life after-sale service.

Dear friend, there’s no need to add a shredder. BS-N130 can process your cables perfectly. If you need to process many cable wires above 30mm, I suggest you can buy 1 set BS-AN120(process 20-120mm cables). For diameters above 60mm, it's better to use the wire stripping machine process first after using the cable granulator machine process, this is better for blades. Our customers usually buy 1 set of cable granulators machine and 1 set of wire stripping machine to coordinate to work.

The price of N series granulators is higher than D series granulators. N series aims for high-end machines, but D series granulators aims for best cost performance machines, they are all both best granulators than other granulators in China market.

C'est un grand honneur pour nous de vous servir.

Envoyez-nous un message si vous avez des questions ou des demandes. Nos experts vous répondront dans un délai d'une heure et vous aideront à sélectionner la machine de capacité appropriée que vous souhaitez.

008613772508206

coppergranulator@bsghrecycling.com

*Toutes vos informations seront gardées strictement confidentielles et notre personnel commercial veillera à ce que vos informations privées soient absolument en sécurité avec nous.

Demandez un devis gratuit

RÉPONSE DANS LES 24 HEURES.

Commencez à grandir avec BSGH maintenant, nous pouvons vous aider à vendre en gros ou à utiliser la machine au mieux.