Description de la vidéo

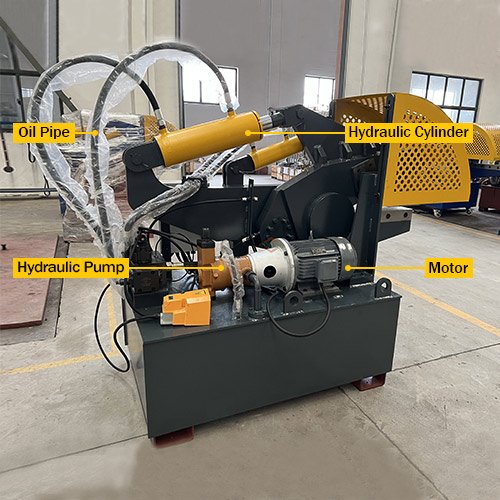

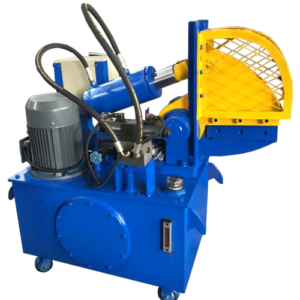

Machine model: AS-1000 Used Alligator Shear Sales to Europe

Customer place: Netherlands

Maximum Shear Capability:1000KN

Maximum Pressure Capability:196KN

Maximum Cutting Blade Opening:320MM

Shearing times of per minutes:7~8 times/min

The customer wants to buy a machine that is light in weight, compact in size and easy to operate, so we recommend AS-1000 hydraulic alligator shear to him. It is relatively cheap, but it has high quality and complete features. Besides, we also offer one-year warranty for each machine. All in all, AS-1000 used alligator shear must be his best choice.