Ⅰ. Einführung

Kupfer Granulatorsind professionelle Geräte, die speziell für das Recycling entwickelt wurden Altkabel. Es kann Altkabel in kleine Partikel von 3 bis 5 mm zerkleinern und dann die wertvollste Metallressource daraus trennen – Kupfer.

1. Kupfergranulatoren – ein breites Anwendungsspektrum

Sie können die Umweltverschmutzung durch Altmetalle verringern, das Recycling und die Wiederverwendung von Kupferressourcen ermöglichen und die Umwelt wirksam schützen. Durch die schnelle Verarbeitung von Altkabeln zu hellen und sauberen reinen Kupfergranulaten und Kunststoffpartikeln können sie auch die Produktionseffizienz von Recyclern auf ein neues Niveau steigern und die Qualität des recycelten Kupfers verbessern, was den Recyclern ideale wirtschaftliche Vorteile bringt. Daher ist es die perfekte Ausrüstung für große Metallrecyclingzentren, Altauto-Recyclingstationen, Schrottplätze, Müllstationen usw.

2. Aktuelle Situation auf dem US-Kupfermarkt

Die Vereinigten Staaten sind der zweitgrößte Kupferverbraucher der Welt. Kupfer leistet einen wichtigen Beitrag zur US-Wirtschaft und spielt in vielen Bereichen wie Elektrizität, Transport, Bauwesen und Energie eine unersetzliche Rolle. Da Kupfer ohne Leistungsverlust viele Male wiederverwendet werden kann, ist es eine ideale Metallressource mit hohem Recyclingwert. Das Recycling von Kupfer ist eine Win-Win-Situation für Gesellschaft und Recyclingunternehmen: Es deckt nicht nur einen großen Teil des gesellschaftlichen Kupferbedarfs, sondern bringt den Recyclingunternehmen auch beträchtliche Einnahmen.

Im Jahr 2023hat das US-Energieministerium Kupfer offiziell in die Liste der kritischen Materialien aufgenommen. Laut ihrer Prognose wird die Nachfrage nach Kupfer im nächsten Jahrzehnt weiter steigen und sich bis 2035 verdoppeln. Dies zeigt, dass recyceltes Kupfer eine immer wichtigere Position in der Kupferversorgung einnehmen wird. In diesem Zusammenhang werden Kupfergranulatoren als fortschrittlichste Technologie zum Recycling von Kupfer auf dem Markt mit ihrer ultrahohen Effizienz und der hohen Qualität des recycelten Kupfers eine entscheidende Rolle im Bereich des Kupferrecyclings spielen.

Ⅱ. Marktprognose für Kupfergranulatoren

Wie wird sich der Markt für Kupfergranulatoren in Zukunft entwickeln? Finden Recycler ausreichend Quellen für Altkabel? Gibt es einen breiten Absatzmarkt für recyceltes Kupfer? Werden die Kupferpreise steigen oder fallen? Welche Fortschritte wird die Kupfergranulator-Technologie machen?

In diesem Kapitel wird die zukünftige Entwicklungstendenz des Marktes für Kupfergranulatoren detailliert vorhergesagt, um Ihnen bei der Beurteilung zu helfen, ob die durch Kupfergranulatoren erzielten Gewinne Ihren Erwartungen entsprechen können.

1. Reichhaltige Quellen für Kabelabfall

Kupfer, das weltweit am dritthäufigsten verwendete Metall, spielt in verschiedenen Branchen eine wichtige Rolle, insbesondere im Elektrobereich. Die einzigartige Leitfähigkeit und Haltbarkeit von Kupfer machen es zu einem unersetzlichen Material im Elektrobereich. Heutzutage ist die Anwendung von Elektrizität fast in jedem Winkel der Welt verbreitet, sodass es auf der ganzen Welt eine große Anzahl von Altkabeln gibt, die Kupferrecyclern eine zuverlässige und reichhaltige Rohstoffquelle bieten und die Stabilität des Kupferrecyclinggeschäfts gewährleisten.

2. Riesige Nachfrage nach recyceltem Kupfer

Mit Blick auf die Zukunft wird die weltweite Nachfrage nach Kupfer mit der Entwicklung von Elektrizität, Automobilen und anderen Bereichen weiter steigen. Kupfer wird knapp sein, und der Abbau neuer Kupferminen allein kann die enorme Marktnachfrage nicht decken, was die Bedeutung des Kupferrecyclings zeigt. Das Kupferrecycling wird ein sehr wichtiger Teil der Kupferversorgung werden und einen breiten Absatzmarkt für Recycler bieten. Daher werden Investitionen in Kupfergranulatoren dem Trend der Zeit folgen und es Recyclern ermöglichen, die Anforderungen der Umwelt und des Marktes zu erfüllen.

3. Stetiges Wachstum der Kupferpreise

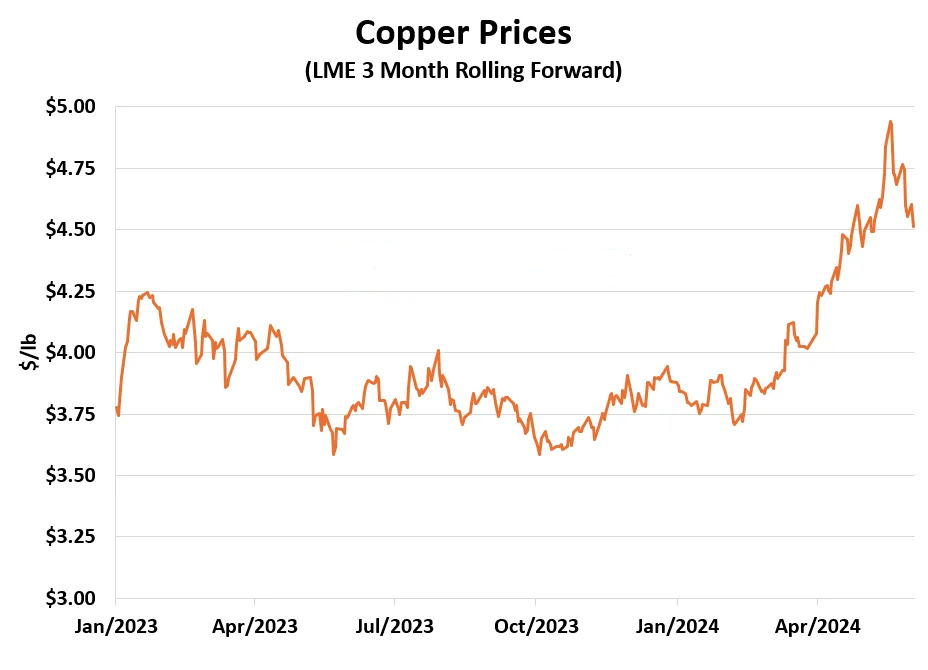

Der Kupferpreis ist ein wichtiger Faktor, der den Gewinn des Kupferrecyclings beeinflusst. Nach Untersuchungen stellten wir fest, dass die Kupferpreise im letzten Jahrzehnt fast ununterbrochen gestiegen sind. Im Jahr 2015 lag der Kupferpreis zwischen etwa $2,5 pro Pfund und $2,8 pro Pfund, und im Juli 2024 hat der Kupferpreis $4,5 pro Pfund erreicht, mit einer Wachstumsrate von 70%. Obwohl es in diesem Zeitraum einige Rückgänge gab, ist der Gesamttrend steigend. Da Kupfer in Zukunft knapp sein wird, glauben wir, dass die Kupferpreise in den nächsten Jahren weiter steigen werden, was den Kupferrecyclern ideale Gewinne beschert.

4. Technologischer Fortschritt bei Kupfergranulatoren

In den Vereinigten Staaten sind die Arbeitskosten sehr hoch. Daher glauben wir, dass Kupfergranulatoren in Zukunft eine höhere Effizienz und eine stärker automatisierte Produktion anstreben werden, um sicherzustellen, dass Recycler höhere Gewinne erzielen und gleichzeitig die Arbeitskosten minimieren können. Darüber hinaus gelten in den Vereinigten Staaten extrem hohe Standards und Anforderungen an den Umweltschutz. In Zukunft werden sich Kupfergranulatoren in eine umweltfreundlichere und schadstofffreiere Richtung entwickeln, um den staatlichen Vorschriften zu entsprechen.

5. Der Aufstieg der Schwellenmärkte

Neben den Vereinigten Staaten verzeichnen auch die Schwellenmärkte der globalen Kupferrecyclingbranche ein rasantes Wachstum. In asiatischen Ländern, insbesondere in China und Indien, legen die Menschen zunehmend Wert auf den Schutz von Metallressourcen und eine nachhaltige Entwicklung, und daher steigen immer mehr Recyclingunternehmen in die Kupferrecyclingbranche ein. Auch in Europa und Lateinamerika wird die Kupferrecyclingarbeit entsprechend der jeweiligen Regierungspolitik und Umweltvorschriften rasch ausgebaut. Da die Kupferrecyclingarbeit in diesen Regionen zunimmt, werden Kupfergranulatoren für sie zu einem wichtigen Instrument zur Verbesserung der Produktionseffizienz.

ZUSAMMENFASSUNG, recyceltes Kupfer verfügt über reichlich Rohstoffquellen, einen breiten Absatzmarkt und ideale wirtschaftliche Vorteile. In Zukunft wird die Kupfergranulatortechnologie auch dem Mainstream der nachhaltigen Entwicklung entsprechen und sich effizienter, automatischer und umweltfreundlicher entwickeln. Gleichzeitig gibt es Schwellenmärkte, die sich der Kupferrecyclingbranche anschließen. Man kann sagen, dass der Markt für Kupfergranulatoren ein großes Entwicklungspotenzial hat.

Ⅲ. Prognose der TOP 6 der meistverkauften Kupfergranulatormodelle in den USA im Jahr 2025

Um Recyclingunternehmen dabei zu helfen, ihre Produktionseffizienz und Wettbewerbsfähigkeit auf dem Markt zu verbessern, haben wir die 6 Kupfergranulatoren zusammengestellt, die sich in den USA im Jahr 2025 am wahrscheinlichsten am besten verkaufen werden. Sie haben ihre eigenen Eigenschaften und Vorteile und können Recyclingunternehmen in verschiedenen Situationen eine starke Unterstützung bieten. Verbessern Sie Ihre Recyclingfähigkeit mit diesen 6 leistungsstarken Kupfergranulatoren und sie werden Ihnen helfen, den Markt schnell zu erobern.

1. BS-F3000 Kupfergranulatormaschine

BS-F3000 stellt den höchsten Wirkungsgrad von Kupfergranulatoren auf dem Markt dar und ist die beste Wahl für große Recyclingunternehmen.

BS-F3000 Kupfergranulator ist ein Standardmodell mit der größten Verarbeitungskapazität und dem umfassendsten Zubehör unter den Kupfergranulatoren von BSGH Granulator und kann verarbeiten 1200 bis 1500 kg Kabel pro Stunde. Die leistungsstarken Funktionen ermöglichen nicht nur die Verarbeitung fast aller Arten von Altkabeln mit einem Durchmesser von weniger als 25 mm, sondern auch von Altheizkörpern.

Komponenten:

- ein zweiachsiger Vorzerkleinerer

- ein Hauptbrecher

- 2 Luftabscheider

- 4 Vibrationssiebe

- 2 elektrostatische Abscheider

- 2 Magnetabscheider

- 2 Staubsammelgeräte

- BS-F3000 = ECO1000 + Vorzerkleinerer + 2 Elektrostatische Separatoren

- BS-F3000 ist auf dem US-Markt am beliebtesten.

2. BS-ECO1000 Kupfergranulatormaschine

ECO1000 stand mehrere Jahre in Folge auf der Bestsellerliste in den USA, daher gehen wir davon aus, dass es seinen bisherigen Ruhm fortsetzen wird.

ECO1000 Kupfergranulator ist der Hauptkörper des BS-F3000. Es ist auch die perfekte Lösung für das effiziente Recycling verschiedener Altkabel mit einer Verarbeitungskapazität von bis zu 1000 kg/Std.. Die gleiche Top-Qualität wie BS-F3000 und der wettbewerbsfähige Preis machen es zum kostengünstigsten Modell unter große Kupfergranulatoren.

Komponenten:

- ein Hauptbrecher

- 2 Luftabscheider

- 4 Vibrationssiebe

- 2 Staubsammelgeräte.

3. BS-N130 Kupfergranulatormaschine

Im Vergleich zum Kupfergranulator BS-F3000 und zum Kupfergranulator ECO1000 BS-N130 Kupfergranulator hat eine geringere Verarbeitungskapazität und kann verarbeiten 400~700 kg Abfallkabel pro Stunde. Die robuste Konstruktion macht häufige Wartung und den Austausch von Teilen unnötig.

Das Design mit niedrigem Energieverbrauch macht es energieeffizienter als 90% oder ähnliche Maschinen auf dem Markt. Die einfache Bedienung und der vollautomatische Recyclingprozess können viel Arbeitskosten sparen. Diese Eigenschaften machen BS-N130 für viele Kunden zur ersten Wahl, wenn es um Kosteneinsparungen geht.

Komponenten:

- Ein Vorzerkleinerer

- Ein Hauptbrecher

- 1 Luftabscheidersystem

- Kupferauslass- und Kunststoffauslass-Vibrationstisch

- BS-N130=BS-N125+Vorzerkleinerer

- Dieses Modell ist das zweitbeliebteste auf dem US-Markt.

4. BS-N125 Kupfergranulatormaschine

BS-N125 Kupfergranulator ist der Hauptteil des BS-N130. Es ist das meistverkaufte mittelgroße Kupferdraht-Recyclingmaschine BSGH Granulator mit einer Verarbeitungskapazität von 300 ~ 500 kg. Wenn Sie derzeit nicht so viele Kabelabfälle haben, aber bedenken, dass Ihr Recyclinggeschäft in Zukunft expandieren könnte, ist der BS-N125 Ihre beste Wahl. Wenn Ihr Recyclinggeschäft expandiert, können Sie Ihrem BS-N125 direkt einen Vorzerkleinerer hinzufügen, um seine Kapazität zu erweitern, ohne auf ein Modell mit größerer Verarbeitungskapazität umsteigen zu müssen, was sehr praktisch ist.

Komponenten:

- ein Hauptbrecher

- ein Luftabscheider

- 2 Rütteltische

- eine Staubsammelvorrichtung

5. BS-D20 Kupfergranulatormaschine

Angesichts der guten Entwicklungsaussichten des Kupfermarktes im Jahr 2025 glauben wir, dass mehr Menschen in den Bereich des Kupferrecyclings einsteigen werden, also kleine Kupfergranulatormaschinen wird auch das Potenzial haben, ein Verkaufsschlager zu werden.

BS-D20 Kupfergranulator ist eine kleine Kupfergranuliermaschine mit einer Verarbeitungskapazität von 200 kg/Std.. Obwohl die BS-D20 eine kleine Maschine ist, weist sie auch eine hohe Qualität und lange Lebensdauer auf, die mit Maschinen europäischer Marken konkurrieren kann, was sie zu einem der Modelle macht, die im Jahr 2025 in den Vereinigten Staaten am wahrscheinlichsten zum Verkaufsschlager werden.

Komponenten:

- ein Hauptbrecher

- ein Luftabscheider

- eine Staubsammelvorrichtung

- ein Vibrationssieb

6. BS-D75 Kupfergranulatormaschine

Seit dem Erscheinen des BS-D75-Kupfers ist es eine der meistverkauften Maschinen von BSGH Granulator und für die meisten Kunden die erste Wahl, wenn es darum geht, ihr Recyclinggeschäft zu starten. Daher haben wir Grund zu der Annahme, dass sich BS-D75 auch im Jahr 2025 gut verkaufen wird.

Der Kupfergranulator BS-D75 ist das kleinste Dreiphasenmodell und kann 75 kg Altkabel pro Stunde. Der BS-D75 ist klein und günstig und damit ideal für Recycler, die gerade erst in die Kupferrecyclingbranche einsteigen und keine stabile Quelle für Altkabel haben.

Komponenten:

- ein Hauptzerkleinerer

- ein Luftabscheider

- eine Staubsammelvorrichtung

- ein Vibrationssieb

Die Herausforderung wir standen vor der Zukunft:

Mit Fortschritten in der Technologie sind BSGH Granulator Kupfergranulatoren immer effizienter und zuverlässiger geworden und bieten eine bessere Leistung als je zuvor als andere Granulatoren auf dem Markt. Unsere Maschinen können auch mit konkurrieren Euro-Granulatoren, und vielleicht sogar übertreffen. Da die Nachfrage nach recyceltem Kupfer steigt, müssen Granulatoren einfacher zu bedienen sein, mit intuitiven Bedienelementen und automatisierten Prozessen, die manuelle Eingriffe minimieren. In Zukunft müssen sich Granulatorhersteller darauf konzentrieren, Maschinen zu entwickeln, die nicht nur größere Materialmengen verarbeiten, sondern auch weniger Strom verbrauchen, Ausfallzeiten reduzieren und weniger Wartung erfordern. Die Balance zwischen hoher Leistung und einfacher Bedienung wird der Schlüssel zur Überwindung der technischen Herausforderungen in der Kupferrecyclingbranche sein.

Ⅴ. Fazit

Nach eingehender Untersuchung und Analyse glauben wir, dass Kupfergranulatoren bis 2025 auf dem US-Markt ein großes Entwicklungspotenzial haben. Es gibt ausreichend Rohstoffe, einen breiten Absatzmarkt und enorme Gewinne. Darüber hinaus glauben wir, dass es 6 Kupfergranulatoren gibt, die im nächsten Jahr in den USA ein Verkaufsschlager sein werden. Indem sie die Produktionseffizienz verbessern und die Kosten senken, können sie Recyclern jeder Größe helfen, schnell Geld zu verdienen.