Normaler Elektromotor

Prozessmotorgehäuse | Motorstator | Motorwelle

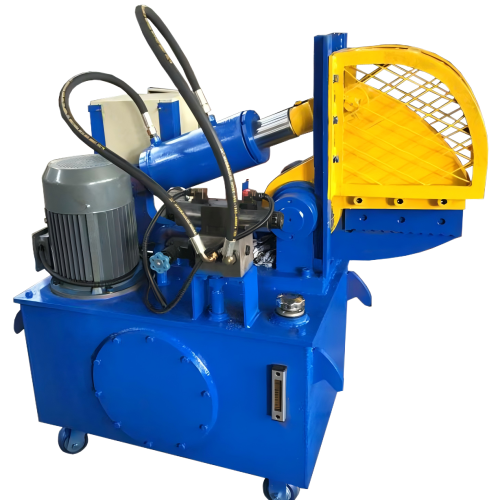

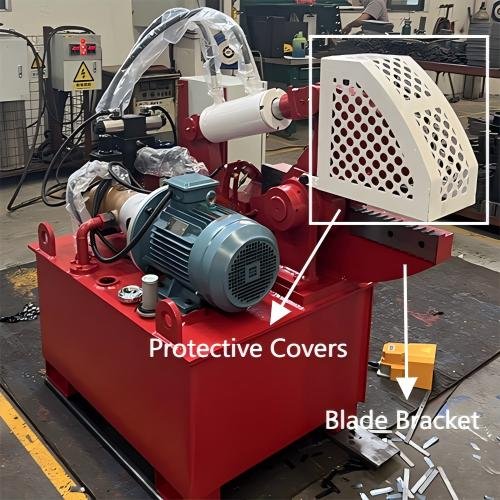

Neue Energiemotor-Recyclingmaschine

Motorgehäuseschneiden | Motorstatorrecycling

Recyclingmaschine für Autostarter

Autostarter-Schneiden | Autostarter-Pressen | Autostarter-Heizung | Autostarter-Ziehmaschine

Recycling von Autolichtmaschinen

Schneidemaschine für Autolichtmaschinen | Ziehmaschine für Autolichtmaschinen

Motorenrecyclinganlage

Recyclinglinie für Motorstatoren | Recyclinglinie für Motorrotoren | Recyclinganlage für komplette Motoren

Transformator-Recyclingmaschine

Für das Recycling kleiner Transformatoren

Kompressor-Recyclingmaschine

Kompressorgehäuse-Schneidemaschine | Kompressor-Stator-Recycling

Recycling von Deckenventilatormotoren

Hauptsächlich zum Recycling von Deckenventilatormotoren

Recycling von Magnetschaltern für Kraftfahrzeuge

Für alle Arten von Auto-Magnetschalter

Recycling des Hinterradnabenmotors von Elektrofahrrädern

Für alle Arten von Elektrofahrrad-Nabenmotoren

Hydraulische Presse

Hauptsächlich zum Pressen aller Arten von Motorteilen | Unterstützung kundenspezifisch