BSM-40 Schrottmotor-Recyclingmaschine

BSGH Granulator scrap motor recycling machine BSM-40 is one of the hottest sale machine among Chinese exporting market, benefit from following outstanding performance:

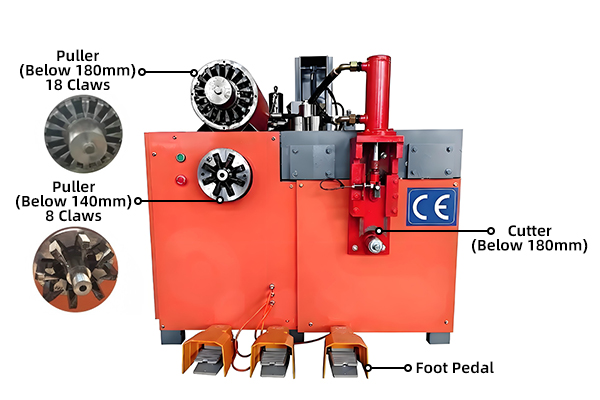

+ Made up of 1 cutter and 3 pullers, can handle 50-500mm scrap motor stator in diameter

+ Driven by hydraulic system and double-flow pump, more stable and powerful

+ One year guarantee and 24/7 online service

+ Only needs one worker to operate

features of BSM-40 Scrap Motor Recycling Machine

BSM-40 is the most popular scrap motor recycling machine in BSGH-Granulator. Specilized in dismantling scrap motor stator, it can cut and pull most common motors below 500mm in diameter, output with market-ready copper coils, widely used from household to scrapyard. You may wonder why BSM-40 so hot, let me tell you the reason:

- Consists of 1 cutting part and 3 pulling parts, only one machine can turn your scrap into profits.

- Equipped with pedal switch, ensure a safe operatation.

- Support customization: voltage, logo, color, motor etc.

- Because of unique dual-flow pump design, the front part and back lifter can work at the same time, saving your time.

- Driven by 2 hydraulic systems, more stable and powerful.

If you need to remove the motor outer casing, please consider our Elektromotor-Schneidemaschine BSM-50, and if you have a big recycling station, then our industrial stator recycling line fits you best.

best-selling Scrap Motor recycling machine BSM-40

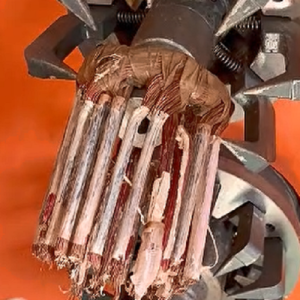

Different from other scrap motor recycling machine, each puller of BSM-40 represents distinct processing capacities. Driven by 7.5kw motor with double-flow pump, the hydraulic stator recycling machine has ability to 100% precisely cut in one pass, then pull intact and pure copper windings out, which can be sold at high price in the recycle market. According to our customers’ feedback, they can payback in one month after using our motor recycling machine BSM-40.

| Modell | BSM-40 Schrottmotor-Recyclingmaschine |

| Leistung | 7,5 kW |

| Stator Range | Between 50-500MM |

Verarbeitungskapazität | 8 Backen: ca. 350 Stück/h |

| 16 jaws: About 160~180PCS/H | |

| Lifter clamp: About 50~60PCS/H | |

| Maximum Operating Current | Approximately 17A |

| Hydraulic Oil | 40KG and temperature should not exceed 75°C |

| Maschinengewicht | 700KG |

| Maschinengröße | 1780*1250*1100MM |

| Packing Weight | 750KG |

| Verpackungsgröße | 1840*1310*1210MM |

How does Scrap Motor Recycling machine work?

Our scrap motor recycling machine is easy to operate, witness how BSM-40 work, you will be amazed at its convenience and multiple functions.

Arbeitsschritte

Place one end of the scrap stator copper winding under the cutting knife, then operator should turn around the stator manually after every cut until the copper winding is totally cut.

Then choose a suitable puller according to your scrap stator diameter and stamp foot pedal to pull the stator copper windings out.

Any of the front part including one cutting part with 2 pulling parts and back hydraulic pliers can work at the same time so that working efficiency can be enhanced greatly.

structure of Scrap Motor Recycling machine

Obviously, the scrap motor recycling machine BSM-40 is consist of Schneiden Teil und Ziehen part, their integration represents a powerful and perfect effect.

- Schneidteil is made up of a crescent blade with a foot pedal, maximum processing range is below 180mm, if you need a larger cutter, please check Elektromotor-Schneidemaschine BSM-50.

- Zugteil has three types of mechanical claws to pull copper windings out, involving 8 claws, 16 claws and a hydraulic lifting clamp. The 8-claw is used to pull scrap stator below 140mm, and the 16-claw is employed to grab waste stator below 180mm, also the hydraulic lifting clamp is made for pulling large stators below 500mm in diameter. Such a big processing range has largely solved the problem of recycling most used motor stators on the market, totally satisfying your needs.

Scrap motor recycling machine BSM-40 Cutting & Pulling System

The BSM-40 scrap motor recycling machine have exclusive ‘1-Cut, 3-Pull’ multifunction design. Unlike standard machines, this unique configuration integrates one powerful cutting blade with three specialized pulling units, allowing you to process a diverse range of motor sizes seamlessly without changing tools

Der cutting head of scrap motor recycling machine BSM-40 is crafted from premium SKD-11 tool steel, renowned for its exceptional high strength and extreme wear resistance in industrial applications. Also the specialized crescent-shaped design matches perfectly to the stator geometry, ensuring a precise cut through the copper coils in a single pass, suitable for cutting scrap stator under 180mm in diameter.

8-claw puller is made of high-strength alloy steel and undergoes specialized heat treatment, achieving exceptional hardness and durability, able to resist cracking even under heavy loads. The sharp hooks provide a relentless grip to extract stubborn copper windings from stators under 140mm swiftly and cleanly.

16-claw puller is forged from high-grade alloy steel and undergoes rigorous quenching and tempering process, making BSM-40 a robust, long-lasting tool capable of withstanding heavy daily use. The hooks supply a powerful, non-slip grip, keeping BSM-40 effortless to extract copper coils from stators under 180mm in diameter.

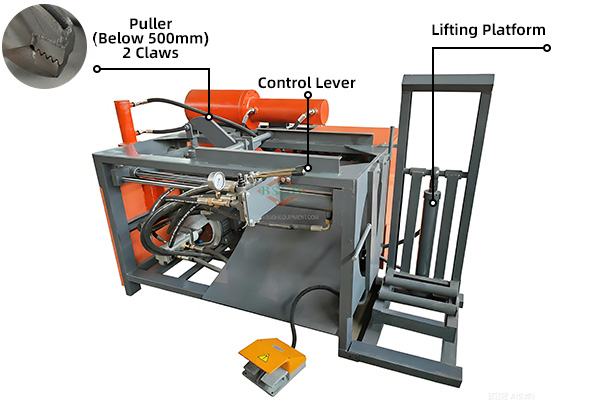

Lifting plier is made up of a ‘two-mouth’ grippers which can bite the copper windings firmly without slipping. And the independent hydraulic system offers constant, surging force, ensuring clamp to reach smooth and complete copper separation every time. Also the lifter platform allows for precise positioning of stators up to 500mm.

advantages Of mature scrap motor recycling machine BSM-40

Einfach zu bedienen

Our scrap motor recycling machine cutting and pulling motions are controlled by “hands-free” foot pedal, allowing operater to keep both hands on the stator for better stability and safety, meanwhile hydraulic control lever keeps worker accurately position the cutting and pulling parts, easy to operate.

dual-flow hydraulic system

Equipped with advanced dual-flow hydraulic system, each part of front cutter/two pullers and the rear heavy-duty lifter can work at the same time without hydraulic pressure decrease. Whether you need to multi-task or utilize a two-person workflow, BSM-40 effectively doubles processing speed and ensures your motor stator recycling stays fast and efficient.

robust structure

The blade of our scrap motor recycling machine is made of heat-treated SKD-11, preventing deform and crack, ensuring a precise cut, machine body and claws use 45# material, more durable and serve for longer time.

Stronger power

BSM-40 scrap motor recycling machine has two cylinders, with a 7.5kw motor, providing a stronger force to extract copper coils continuously—even from the toughest, most tightly wound stators while making sure your motor recycling runs smoothly without delay.

Packing and shipment

To guarantee your scrap motor recycling machine arrives in perfect condition, every BSM-40 undergoes our strict Three-Stage Protection before leaving the factory:

- Moisture Barrier: First, the entire unit is tightly wrapped in industrial-grade protective film to avoid moisture and corrosion during sea transit.

- Impact Resistance: The machine is then secured within a custom-built, reinforced plywood case, preventing shock and physical damage or scratching.

- Trusted Logistics: Finally, we utilize premium trucking partners by LCL shipping, ensuring a stable, vibration-free transport from our workshop to the seaport.

Why Choose us?

Your recycling business deserves equipment that works as hard as you do. Backed by 30+ years of manufacturing experience, BSGH delivers the BSM-40 scrap motor recycling machine —a machine designed to turn complex scrap motors into pure profit.

1. Comprehensive Material Handling

We understand that scrap comes in all shapes and sizes. As a professional solution provider, except the perfect BSM-40 is engineered to process a variety of common scrap motors. We also have other machines for DC motors, vehicle starters, car motors, transformers, compressors, and heavy industrial stators. Our machines are built to handle all your scrapyard waste motors.

2. Engineering & Customization

There is no “one-size-fits-all” machine in industrial recycling. Whether you require specific voltage configurations, custom branding, or specialized modifications to fit your workflow, our engineering team is ready to adapt. We provide a wide range of customization services to ensure the equipment fits your facility perfectly.

3. Commitment to Your Success

When you choose us, you are gaining a partner, not just a vendor. From the initial consultation to post-purchase support, our experienced workforce coordinates with you at every step. We are driven to produce results that match—and often surpass—your expectations, ensuring your investment turns into profit quickly.

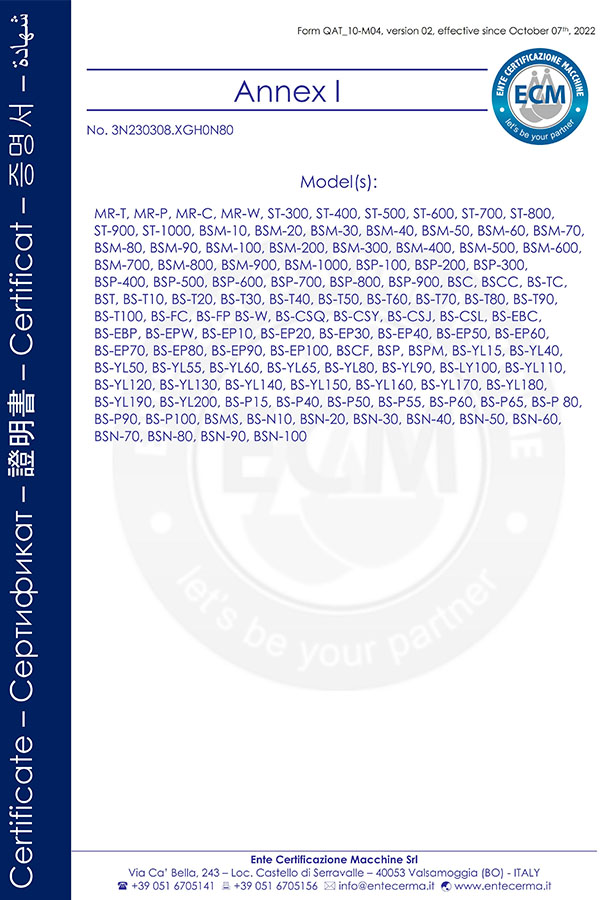

CE for scrap motor recycling machine

Häufig gestellte Fragen

Can the scrap motor recycling machine dismantle my car motor?

Sorry, it can't, and our scrap motor recycling machine BSM-40 is only able to dismantle most common scrap motor stator below 500mm in diameter. As to your car motor, please check our specilized car motor wrecker machine.

Can scrap motor recycling machine BSM-40 handle repaired motors (with adhesive or bamboo)?

Sorry, BSM-40 can't handle them just dismantle common scrap motor.

I want to buy some worn parts for the scrap motor recycling machine together, what's your suggestion?

You'd better buy extra cutting blades and pulling claws as spare use, do not worry, our scrap motor recycling machine can serve for a long time under normal use.

May I add my company logo on the scrap motor recycling machine?

Of course, we can customize your logo on the scrap motor recycling machine, also motor, color and voltage support customization.

My scrap motor stator is below 500mm in diameter, but not remove the outer casing, how to recycle the copper coils inside?

Do not worry, you can buy our Elektromotor-Schneidemaschine BSM-50 with BSM-40 scrap motor recycling machine together, totally handle your entire used motors.

How the scrap motor recycling machine process heavy or large stators?

Don't worry. BSM-40 hydraulic clamp is equipped with a lifter. When handling heavy stators, it can assist in supporting and adjusting the height, making the pulling process easier.