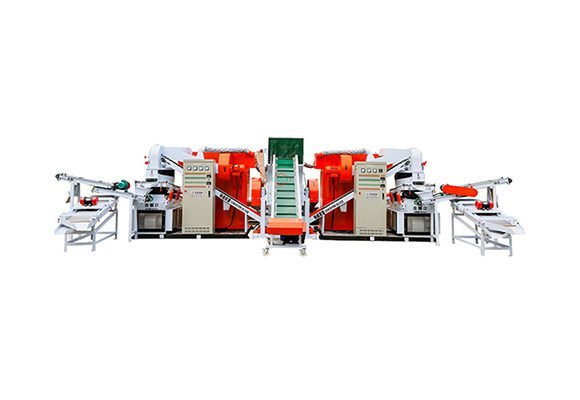

BS-F3000 Großer Kupferkabelgranulator – Versand heute in die USA

Nachrichten Kontaktieren Sie uns E-Mail:coppergranulator@bsghrecycling.com Kontakt Frau Wang TEL: +086 13772508206 Website: www.bsghgranulator.com Geschichte des Kupferkabelgranulators Am ersten Tag im Juli lieferte BSGH Granulator erfolgreich