newest gear reducer wire stripping machine

BSGH Granulator Gear Reducer Wire Stripping Machine with Variable Frequency Motor:

Processing range up to 120 mm

Up to 56% energy savings

100% separation rate with precise cutting

Variable frequency control for easy speed adjustment

BSGH Granulator R&D team has newly developed wire stripping machine with variable frequency & energy-saving gear reducer, the first one all over the worldwide market, making us a recycling machine manufacturing leader, featuring:

- Original Anti-slip shaft design, invented by BSGH — others only imitate;

- Serrated shaft for a firm, stable grip on cables;

- Fully enclosed casing guarantees machine protection and worker safety;

- Compact structure, looks beautiful, especially favoured by American and Eurepean market;

- Small footprint, making your workshop layout more flexible;

- No need to adjust the handle frequently.

- Belong to the most stable AC Series wire stripping machine;

- Wide application range, suitable for households, scrapyards, and recycling centers

newly development gear reducer wire stripping machine zu verkaufen

Unser Abisoliermaschine with gear reducer is a heavy-duty, industrial-grade solution designed for processing tough and demanding cables. It delivers noticeably stronger stripping force when handling high-density wires, multi-core cables, armored cables, and submarine cables.

At the core of its performance is a variable-frequency, energy-saving gear reducer, which provides high torque output while maintaining stable and smooth operation.

This combination ensures reliable stripping performance, reduces operating stress on the machine, and effectively eliminates common stripping problems such as slippage, jamming, or incomplete separation.

With its balanced power, stability, and energy efficiency, the BSGH wire stripping machine offers long-term reliability and real operating value, making it a solid investment for professional recycling operations.

- Range: 1~62MM

- Power: 3KW + Reducer

- Feeding inlet: 11 round holes + 2 frame holes + 1 pressing hole

- Blades: 21 blades ( dual 8 blades + 5 single blades ) + 2 frame blades

- Price: USD699

- Bereich: 1 ~ 72 mm

- Power: 2.2KW + Reducer

- Feeding inlet: 12 round holes + 2 frame blade holes + 1 pressing hole

- Blades: 21 blades ( dual 9 blades + 3 single blades )+ 2 frame blades

- Price: USD899

- Range: 10-120MM

- Power: 3KW + Reducer

- Feeding inlet: 1 hole

- Blades: 2 blades

- Feature: Hottest sale model among AC series wire stripping machine with gear reducer

- Price: USD1399

customer case

Customer: Steve

Location: Netherlands

Machine Model: BS-AC80 Automatic Wire Stripping Machine

Motor Power: 2.2 kW

Background:

Steve runs a recycling business in the Netherlands, processing waste cables up to 60 mm in diameter on a daily basis. His previous wire stripping machine was outdated and difficult to operate, often causing interruptions and high electricity consumption.

Lösung:

Looking for a more reliable and efficient solution, Steve searched online and discovered BSGH. After discussing his requirements, he decided to upgrade to the BS-AC80 Automatic Wire Stripping Machine.

During testing and operation, the BS-AC80 showed smooth, stable performance. It grips thick cables firmly and strips the insulation cleanly, with no jamming and no hesitation. More importantly, the energy-saving motor helped reduce power consumption.

After putting the machine into use, Steve shared his feedback:

“It works smoothly and saves about 50% energy. I’m very satisfied and would recommend it to others.”

gear reducer wire stripping machine Working process

Our gear reducer wire stripping machine with a variable frequency motor is integrated for one purpose to efficiently transform your scrap wire into high-purity copper wire and plastic layer. You can put it into a better use with right working process, ensuring 100% separation rate and maximum throughput.

Arbeitsschritte

Vorsichtsmaßnahmen vor dem Gebrauch: Um einen sicheren Betrieb zu gewährleisten, empfehlen wir Ihnen dringend, die Maschine vor der Verwendung zu überprüfen.

• Check whether the plug connect well.

• Plug the power, start the wire stripping machine, and check whether it works well.

• In order to protect the blades and expand their lifespan, we professionally suggest you cut the plugs before you feed the wires with plugs.

Schritte zum Maschinenbetrieb:

- Select a suitable feeding hole that matches the diameter of the wire and feed into the machine.

- Then scrap wire will be cut in two sides or single side.

- Finally, plastic layer and copper wire come from outlet.

If the wire is not peeled completely, please adjust the handles to make the gap closer between shaft and blades, then strip the wire again.

advantages Of gear reducer wire stripping machine

Adjustable handle design

The adjustable handle allows for precise control within a few seconds, reducing downtime and making the processing range more flexible. Besides, the shape is designed according to the human hand’s grip curve, providing a comfortable grip, friendly to users.

button switch

The PLC control panel adopts button design, just press, you can easily control the wire stripping machine with gear reducer, automatic and convenient, besides, there is a big red button for emergency stop, easy to operate, suitable for new hand.

easy to move

Our gear reducer wire stripper machine has four universal wheels (2 big casters + 2 small wheels) , one person can move it, very flexible, so you can strip used wire anywhere, more convenient.

Robust structure

The blades and shaft of our wire stripping machine with gearbox is made of 9CrSi material and heat treated, making your wire stripper high hardness, wear-resistant, serving for longer time.

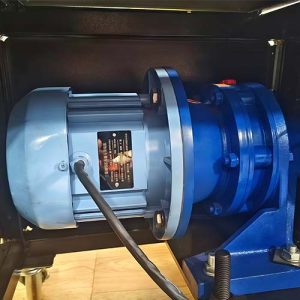

Revolutionary Power System: Variable Frequency Energy-Saving Gear Motor for Wire Stripping Machine

Our variable frequency & energy-saving gear reducer motor optimizes the entire machine performance and economic value of a wire stripping machine. As the name suggests, it has variable frequency allows for precise control over the motor torque, check the benefits and comparison with traditional asynchronous motors:

- 56% energy saving.

- Low operation noise.

- Adjustable speed for wire stripping.

- Stronger power makes stripping more complete.

- Keep a better performance and longer lifespan.

| Technique Data | Variable Frequency Energy-Saving Gear Motor | Traditional Asynchronous Motor |

| Torque Performance (power) | 2200 watts, 144N·m | 4000 watts, 123N·m |

| Energieaufnahme | 2200 watts, 1.76 kw/h | 4000 watts, 4 kw/h |

| Motor Vibration and Noise | Brush-less construction, no electromagnetic noise and vibration | High electromagnetic noise and vibration |

| Motor Life and Stability | Fewer components, high reliability, low failure rate | Many components, low reliability, high failure rate |

| Starting Performance | Soft start, smooth speed increase, minimal shock | Hard start, instantaneous full voltage operation, high shock |

| Motor Size and Weight | Only 70% of traditional motors, more flexible installation | Large footprint and heavy |

Raw material and end product

The gear reducer wire stripping machine from BSGH Granulator enables to solve diverse types of tough wires such as high-densiy wire, armoured wire, multi-core wire, and a small amount of submarine wire, etc., output with pure copper wire and insulating plastic layer, hot selling all over the world especially in USA and Europe market.

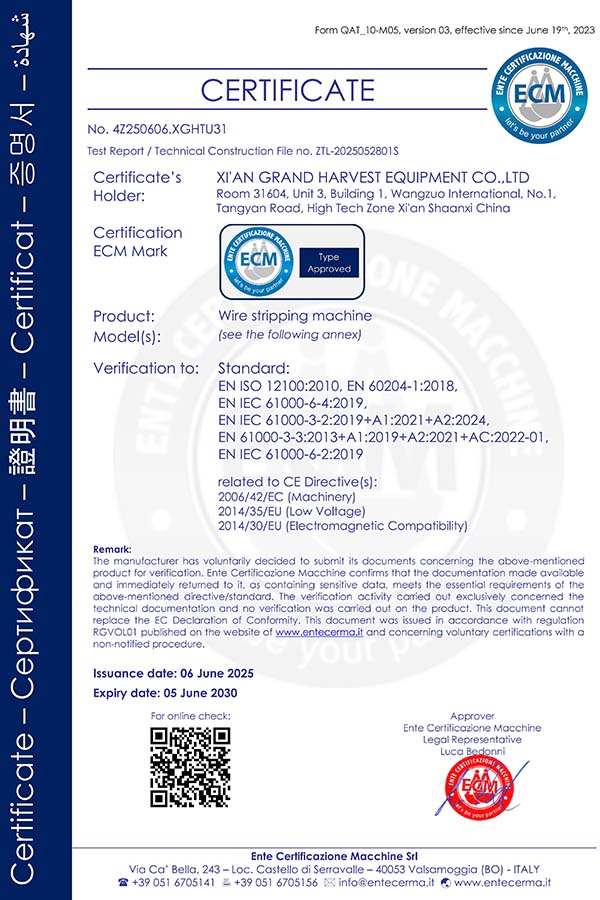

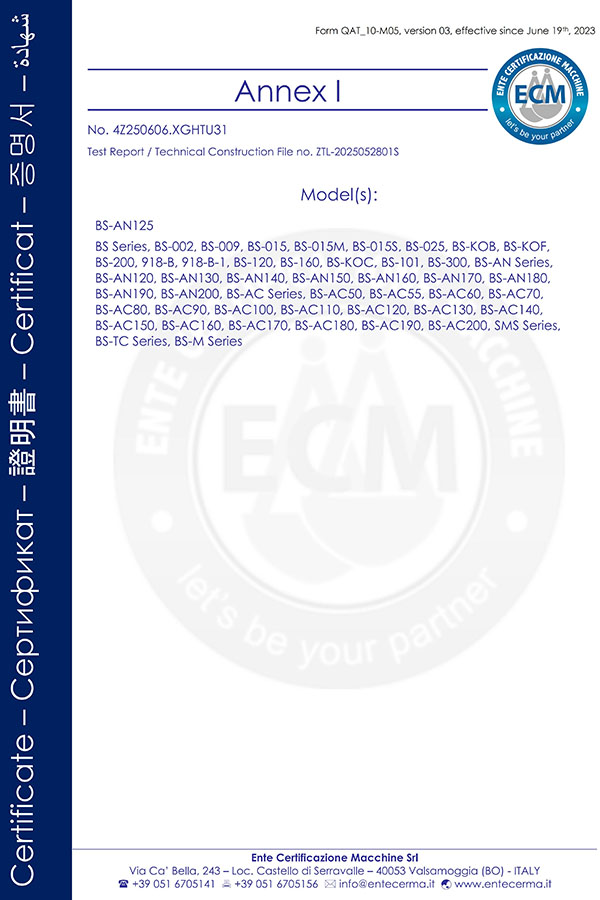

Warum wir?

With over 30 years of dedicated experience, BSGH Granulator has grown into a leading manufacturer of industrial wire stripping machines. We take every customer concern seriously and continuously refine our products, services, and quality standards to solve real recycling challenges. Today, BSGH machines are trusted by customers in more than 80 countries worldwide.

- OEM & ODM service: Our experienced designers and manufacturing engineers work closely with customers to develop customized wire stripping solutions. From special cable structures to unique scrap conditions, we help you solve your specific recycling problems and improve productivity.

- Complete range wire stripping models: We offer a full portfolio of models, including standard wire stripping machines, armoured cable stripping machines, Und ACSR wire stripping machines, covering a wide range of scrap wire applications.

- Strong Production & Supply Capacity: With annual sales reaching approximately USD8 million in both domestic and overseas markets, BSGH maintains stable production capacity and sufficient inventory to support fast delivery.

- Professional Quality Control:Our R&D team specializes in the development of gear reducer wire stripping machines. Each machine undergoes strict in-house testing, and selected models are tested in real recycling operations before market release—ensuring proven performance and mature technology.

- Reliable Sales & After-Sales Support: From machine selection to inspection and after-sales service, our sales team provides full-process support. A one-year warranty is included, ensuring long-term reliability and peace of mind.

What Our Clients Say

Our advanced wire stripping machine with gear reducer has exported 1000 sets worldwide so far. Below, you’ll find real feedback and reviews from recyclers who have turned investment into higher profits. Their stories becomes the most convincing proof, showing a trustworthy investment.

FAQ about gear reducer wire stripping machine

Can your gear reducer wire stripping machine handle aluminum wire?

Of course, our gear reducer wire stripping machine is industrial-grade, totally able to handle your aluminum wire.

how much is gear reducer wire stripping machine harbor freight fee?

For wire stripping machine harbor freight, it will rely on the model you choose and the quantity you buy. Normally for small quantity we will send LCL; for big quantity we will send by full container, for specific details, you can consult our staff.

How often should the blades of gear reducer wire stripping machine be replaced?

It depends on your usage. The blades of our wire stripping machine typically have a long lifespan under normal use. You'll need to replace the blades when it is blunt or notched.

How should I do if I can't adjust the wire strippng machine properly?

Dear friend, do not worry, first, please check the user manual, if still not work, then just contact our sales staff, they will give you 24/7 online service to adjust the machine till normal use.

How can I know the blades of gear reducer wire stripping machine are broken ?

When you find the wire can not processed well or can not cut the outer insulating layer smoothly, indicating the blade is broken. Suggest buy extra blades for spare use.