Best heavy equipment from China

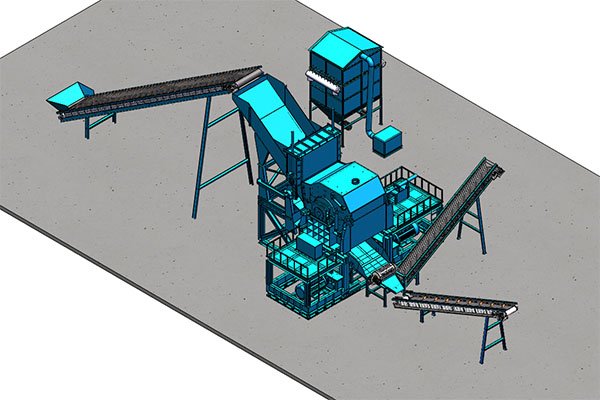

BSGH Granulator offers a variety of heavy equipment to help you move, cut, shred, and pack various large and heavy materials. These machines are designed specifically for industrial operations, powerful and built to last.

Premium heavy duty equipment for sale

Heavy equipment refers to large, powerful machines used in scrap metal recycling, construction, mining, and other industries for tasks like digging, lifting, and moving materials. These machines are essential for large-scale operations and include a wide variety of vehicles and tools. Whether you’re running a scrap yard sorting tons of metal or managing a construction site moving concrete and debris, our heavy-duty equipment is built to perform under pressure. Designed for maximum power, efficiency, and durability, these machines handle jobs that typical equipment can’t.

Our machines can process ferrous/non-ferrous scrap with minimal downtime; crush and move concrete, rebar, and debris; and compact bulky materials into profitable and easily transportable cubes, turning scrap into profit.

These are more than machines—they’re your toughest, most reliable partners in the field.

Heavy equipment list

We supply a full range of medium and heavy-duty machinery to meet the diverse needs of recycling facilities, transfer stations, and scrap yards—regardless of size. Our equipment is built for durability, efficiency, and adaptability, making it ideal for handling metals, plastics, construction waste, e-waste, and more.

Engineered to perform in the most demanding environments—such as scrap yards, recycling centers, and port operations—our material handler machines range from lightweight to heavy-duty models, all delivering high-efficiency material processing with exceptional precision and durability. Equipped with a 360-degree continuous rotation system and a range of grapples with capacities from small 0.3 cubic meters to bigger capacity, from small tonnage to big tonnage, these machines offer an operating cycle of 4 to 6 times per minute, ensuring fast, reliable, and consistent performance across a wide variety of applications

heavy forklift for sale

Our range of heavy forklifts is designed to meet the diverse needs of modern material handling:

- offering a wide selection of models, including electric forklifts, stand-on forklifts, and powerful diesel variants.

- With load capacities tailored to various operational requirements, from light-duty to high-tonnage lifting.

- Our forklifts provide flexible solutions for warehouses, manufacturing plants, and industrial logistics.

Built for durability and engineered for efficiency, each model delivers exceptional performance, operator comfort, and long-term reliability—making it the ideal choice for demanding work environments.

excavator grapple

Der Drehbarer Baggergreifer connects to your excavator’s auxiliary hydraulics, providing fast, reliable control for handling bulk, irregular, or loose materials. Available in 4- or 5-tine configurations, the heavy-duty steel claws are operated directly from the cab, allowing operators to securely grip, lift, and place materials with precision. The integrated hydraulic rotator offers full 360-degree rotation, enabling accurate load positioning for truck loading, shredder feeding, stockpiling, or material transfer across demanding job sites such as scrap yards, demolition zones, and recycling facilities.

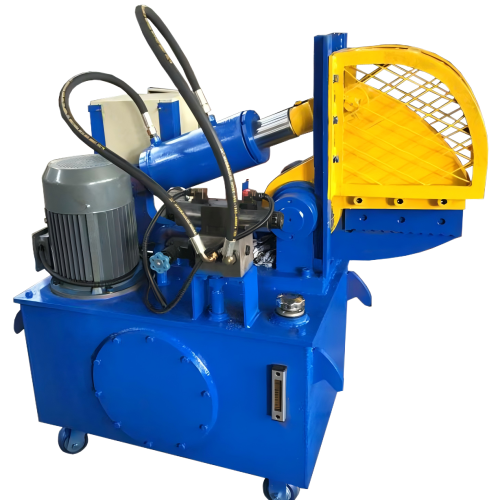

horizontal shearing machine

Der container horizontal shearing machine is engineered for efficient, high-capacity cutting of both ferrous and non-ferrous materials. Built for continuous, heavy-duty use, it delivers powerful shearing performance while maintaining smooth, stable operation. With a fully enclosed design, low noise output, and robust safety features, this machine is ideal for scrap yards, recycling centers, and industrial processing sites that demand speed, reliability, and operator protection. It’s the smart solution for high-throughput metal processing with minimal downtime.

used shear baler

Der baler shear combines the core functions of a baler and a shear into a single, efficient machine. Unlike a standard metal baler that compresses scrap into tightly packed blocks, the baler shear applies moderate pre-compression—just enough to align and compact the material—before precisely shearing it to the desired length or thickness. This integrated design enhances processing efficiency, reduces handling steps, and offers a more flexible solution for cutting bulky or irregular metal scrap in recycling yards and processing facilities.

Dual-shaft shredder machine

Designed for demanding recycling and waste handling operations, our dual-shaft shredders can consistently shred the toughest materials. From electronic scrap to scrap cars, they can promise consistent shredding efficiency and uniform output size. If you require a specific end product size, we can also customize it.

Hammermühlenzerkleinerer

Designed for recycling and demolition applications, the hammer mill shredder is capable of crushing concrete, car bodies, scrap metal, and more. Compared with conventional shredders that use cutting blades, this machine adopts wear-resistant hammers to deliver powerful impact crushing. This not only allows it to process large, hard, and tough materials but also significantly reduces maintenance frequency and minimizes downtime.

Scrap metal baler

Unser industrial-grade metal balers efficiently compress scrap metal, machining chips, demolition debris, and other recyclables into dense, uniform cuboid bales—making them easier to store, stack, and transport. This helps significantly reduce mogistics costs and scrap yard footprint. Available in a range of compression forces (tonnages) to suit different material volumes and densities, each baler is powered by a robust hydraulic system for stable, consistent operation and long-term reliability. To ensure maximum durability in harsh working conditions, key wear surfaces are reinforced with HARDOX® wear-resistant steel, extending machine life and minimizing maintenance needs.

Gantry shear

For tough and bulky metal scrap—such as steel bars, thick plates, scrap copper, scrap iron, and even complete car bodies—our gantry shear offers unmatched cutting power and operational efficiency. Designed to handle the most demanding recycling and demolition tasks, it delivers a shearing frequency of 2–3 cuts per minute, enabling high-throughput processing in scrap yards and steel mills.

Available in various sizes and configurations, our gantry shears can be tailored to meet different processing volumes and material types from medium-duty operations Zu large-scale industrial applications. All models have a hydraulic drive system for stable performance, reduced maintenance, and long service life even under continuous heavy-duty operation.

Different Heavy equipment videos

We have a solution for every industrial operation you need. Each of our machines is designed to operate continuously and consistent performance over time, helping you push your operations to new levels of production and efficiency.

How to Choose the Right Heavy Equipment?

When selecting heavy equipment, choosing the right machine often depends on the type of material you’re processing and your actual needs. Below is a practical comparison of machines with similar functions, helping you find the best fit for your operational needs.

Scrap metal baler vs. Baler Shear

Scrap metal baler has a single baling function. The compressed bales are more compact, and the volume is fixed. When you have higher requirements for bale density, you can choose our metal baler.

Baler Shear does not compress the bales so compactly, but it has a cutting function. You can freely cut the bales to the required thickness. Choose a baler shear when you need both compaction and cutting in one machine.

Dual-shaft Shredder vs. Hammer Mill Shredder

Zweiwellenzerkleinerer: low speed, high torque, wide range of applications, from plastics, tires, wood, to scrap cables, car engines, and other metals, all can be easily shredded.

Hammer Mill Shredder: high-speed impact crusher for brittle materials such as car shells, aluminum products, concrete, etc., suitable for large-scale metal processing, which requires high-intensity crushing.

Container shear machine vs. Gantry Shear

Container shear machine: Designed for compact, irregular scrap, offering high throughput and automatic feeding. Works well with bundled or loose material.

Gantry shear is your choice for oversized, long-format steel.

Every operation is unique. If you’re unsure which machine best fits your material type and production goals, contact us, and we will provide you with professional advice.

heavy equipment Key features and advantages

heavy-duty

Built with robust structures, they withstand tough working conditions, reducing the need for frequent repairs and extending service life, which helps lower long-term operational costs.

Multifunktional

Versatile enough to adapt to multiple industrial sectors, from waste management and recycling to construction, making them an ideal choice for businesses with varying operational needs.

easy to operate

Equipped with an advanced PLC control system, they offer smooth operation, allowing operators to maneuver with accuracy, even in complex work environments.

hohe Effizienz

Our heavy metal equipment can optimize productivity and streamline workflow processes, minimizing downtime between tasks and increasing overall output in daily operations.

Worry-free after-sales service

Designed for easy maintenance, with accessible components and clear service instructions, simplifying routine checks and reducing the time spent on upkeep.

Zertifizierung

All our heavy equipment has CE-Zertifizierung.