I. Einleitung

An industrial shredder isn’t just a piece of equipment; it’s the engine of your profitability. Whether you’re processing scrap metal, e-waste or other materials, this powerful machine is a significant investment.

Like any other high-performance industrial machine, shredder requires regular maintenance to keep its best performance. If it is not maintained for a long time, the machine may cause failure or even downtime, reducing profits. Proper maintenance is the first defense against them. By following a consistent maintenance schedule, you can:

- Reduce machine failures: Shredder maintenance can minimize the risk of minor issues turning into catastrophic and costly failures, preventing crusher from shutting down during operation.

- Maintain optimal performance: Ensure your shredder is always at the best condition, capable of processing maximum capacity and consistent material sizes.

- Enhance operational safety: A well-maintained shredder ensures a safer working environment for your entire team.

- Extend service life: Proper maintenance can protect critical components, prolong its lifespan and maxmium its value from your investment.

Whether you’re an experienced operator or planning to purchase the first industrial shredder, this manual provides professional maintenance steps for machine operation.

II. How to Maintain Your Shredder: 7 Essential Shredder Maintenance Tips

The best daily shredder maintenance checklist is: 1) Blade Check: Inspect blades and bolts for cracks or looseness. 2) Chamber Clearance: Ensure the cutting chamber is clear of wrapped debris. 3) Sound Check: Listen for grinding or whining from the motor and reducer.

This simple routine is your first line of defense against major breakdowns. While these three daily actions are critical, a complete maintenance strategy goes deeper. Below, we will break down in 7 essential tips that cover these basics in more detail and introduce other critical checks to ensure long-term performance and reliability.

SAFETY FIRST: Before You Start Any Maintenance

Before touching any part of the shredder, ensure its chamber is empty, then turn off the shredder and disconnect all power. Safety is non-negotiable.

Step 1: The Daily Inspection

Before daily operation, please give the shredder a thorough inspection to check for the following abnormal conditions:

- Check the crusher shell for cracks, deformation or loose screws.

- Check signs of oil leakage at each lubrication point.

- Check the feeding inlet and outlet for material blockages. Clear any blockage in time to avoid processing interruptions.

- Check the power cord for damage or deterioration and verify the plug connection is secure.

- Prior to startup, test all control switches and overload protection devices to ensure proper responsiveness and reliability, confirming the safety operation of electrical system .

In conclusion, early detection of minor issues prevents escalation into major failures.

Step 2: Clean the Shredder Thoroughly

Material debris and dust negatively impact not only visual clutter but also the performance. It is essential to keep routine cleaning.

Internal cleaning: After shutdown, check the crushing chamber and remove remaining materials if have(it’s better to let the shredder crushing all material and empty then stop off), especially the accumulated materials at the corners, blade gaps and screens, to prevent the materials from getting damp and agglomerating or corroding the equipment.

Keep the area around the machine clean, dry, and free of any clutter or obstacles. A tidy workspace helps prevent accidents and ensures the shredder operates smoothly.

Step 3: Check and Maintain the Lubrication System

Proper lubrication is essential for the performance, reliability, and service life of your shredder. Inadequate or improper lubrication can cause overheating, accelerated wear, and even mechanical failure.

Inspect lubricant levels regularly, especially in the gearbox and other critical components. Ensure all moving parts—such as bearings, shafts, and joints—are greased with the correct type and amount of lubricant as specified by the manufacturer.

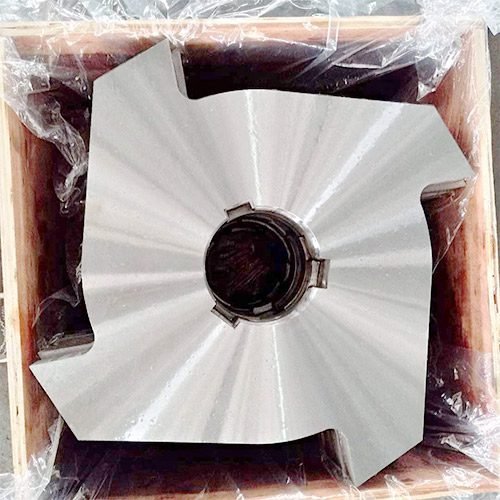

Step 4: Periodically Replace or Sharpen Blades

Blades are the key components of shredder, directly determining crushing performance. Therefore, it is crucial to keep their integrity and sharpness.

Check blade sharpness and wear: Dull blades tear and crush materials instead of cutting it, which generates excessive mechanical stress on the motor and drive systems, increasing energy consumption and affecting the machine’s working performance.

Check for damage: Inspect blades for chips, cracks or breaks.

Sharpen or replace as needed: If you find the dull blades or poor-performing shredding, please remove dull blades promptly or either sharpen or replace them with new blades.

Step 5: Inspect Electrical Components

The power supply and control systems of shredders require careful maintenance. A routine check can avoid system shutdown and downtime.

Check wiring and connectors for signs of wear, corrosion or looseness.

Check the control panel for any warning lights or error messages.

Ensure all sensors are clean and properly positioned.

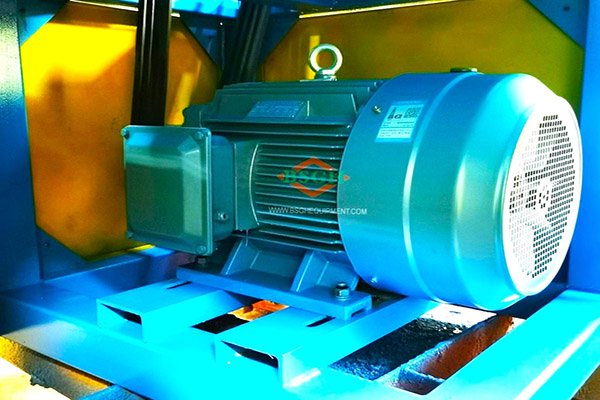

Step 6: Monitor the Motor and Gearbox

The motor and gearbox serve as the heart and muscle of your shredder. Pay attention to their operational sounds and physical vibrations.

Inspect for unusual operational sounds including grinding, whining or knocking noises.

Check for signs of overheating (you can use an infrared thermometer for a precise measurement).

Check for any lubricant leaks around seals and gaskets. An abnormal load or sound indicates potential issues and requires immediate inspections.

Step 7: Test All Safety Measures

In any workshop or facility, safety should always come first, especially when working with industrial shredders. A few simple checks can make a big difference.

Start with the emergency stop button. Make sure it’s clearly marked, easy to reach, and stops the machine the moment it’s pressed. If there’s any delay, or if it feels loose or unresponsive, it needs to be fixed immediately.

Next, check all safety guards and interlock systems. Guards should be firmly in place, and the machine shouldn’t run if any of them are open or removed. If it does, that’s a serious issue that must be addressed right away.

These safety systems aren’t just there to meet regulations—they’re there to protect your team and keep operations running without unexpected downtime. Make these checks part of your regular maintenance routine.

III. Top 5 FAQs About Shredder Maintenance

We are pleased to accept questions all the time. Here are some quick and straightforward answers.

1. How often should I inspect my shredder?

It’s best to have a tiered schedule.

Daily: A quick walk-around inspection (step 1) before operation;

Weekly: A more thorough check including cleaning, lubricant levels and a closer inspection at the blades;

Monthly/Quarterly: A comprehensive inspection covering all 7 steps, including lubrication and electrical checks, based on the manufacturer’s recommendations and your operating hours.

2. When should I sharpen or replace shredder blades?

This depends heavily on the material you’re shredding and the operating hours. Watch for performance not just at a fixed time :

Decreased throughput (taking longer to shred the same amount of material);

Poorly shredded, ragged output;

Increased motor amperage;

Increased noise or vibration.

3. What are the most common signs that a shredder needs maintenance?

The machine will always tell you something is wrong. Watch for:

Unusual Noises: friction, squealing or banging;

Excessive Vibration: bigger operational vibration;

Performance Drop: Slower shredding or poor output quality;

Overheating: The motor or gearbox runs too hot to touch.

4. What safety precautions should I take during maintenance?

Wait for the machine to stop: Make sure all parts have stopped completely before reaching inside the machine.

Power off: This is the most critical step. Make sure the machine is thoroughly powered off and cannot be started accidentally.

Personal Protective Equipment (PPE): Always wear appropriate including safety glasses, steel-toed boots and heavy-duty gloves.

Never Work Alone: Confirm there is another person nearby, especially for more intensive repairs.

5. What’s the average lifespan of a well-maintained shredder?

With proper and consistent maintenance, a high-quality industrial shredder is a long-term asset. A well-maintained machine can usually last 15 to 20 years or even longer.

IV. Conclusion: Maintenance is an Investment, Not an Expense

Consider shredder maintenance not as a cost, but as an investment in future, safety, and long-term profitability.

By building these steps into your daily operations, you can protect your crew, your equipment, and your time. A proactive approach ensures your shredder stays a reliable, high-performing workhorse for years to come.

Treat your shredder well — and it will treat your business even better.

Tags: shredder types; Schredderklingen; #1200 shredder;