Ⅰ. Einführung

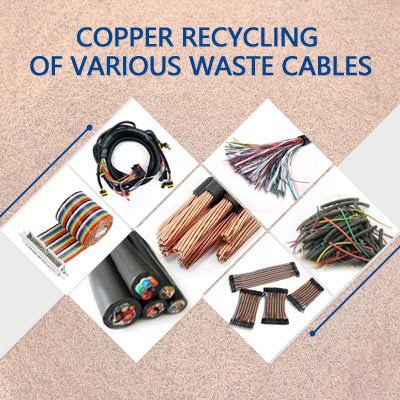

COPPER is an extremely important metal resource. Due to its good electrical conductivity, thermal conductivity and plasticity, copper is widely used in electrical, construction, manufacturing, chemical and metallurgical industries. Nowadays, with the increase in the number of scrap copper wires and the demand for copper, people’s awareness of recycling scrap cables is also gradually increasing. Recycling scrap copper wires can not only reduce the waste of metal resources, reduce the mining of new copper mines, protect the environment, but also bring ideal economic benefits to enterprises.

AT PRESENT, we mainly have four methods to recover copper from scrap copper wires. This article will briefly introduce these four methods for you, and analyze the ADVANTAGES Und DISADVANTAGES of each method by comparison.

Ⅱ. Four Different Copper Separation Techniques

1. Burning Method

Burning method is the TRADITIONAL METHOD for recycling waste cables. Its principle is to use high temperatures to burn the waste copper wires. When the plastic skin of the waste cables is burned away, the copper wires can be recycled. This method is an informal method of recycling waste cables. It is characterized by low cost, but it will cause serious pollution, also the copper will be sell LOWER PRICE in this recycling method.

2. Manual Stripping Method

Manual stripping of waste cables requires some BASIC TOOLS Und SKILLS. This method mainly uses wire strippers, blades, and other tools to manually cut the plastic layer of the waste cables and then pull out the internal wires. This method does not require machine costs and does not affect the environment, but due to its low processing efficiency, manual stripping is gradually being ELIMINATED by the market.

3. Wire Stripping Machine

Der Abisoliermaschine is an AUTOMATIC device specially used for stripping the insulation layer of waste cables. It has multiple feeding ports of different sizes. After the cables enter the machine from the feeding ports of similar sizes, the high-speed rotating blades will cut their plastic skins, thus achieving the purpose of stripping. The wire stripping machine is suitable for various waste cables with a diameter of more than 30 mm. Some specially designed models can even handle waste cables with very hard insulation layers such as Panzerdrähte Und Drähte mit hoher Dichte.

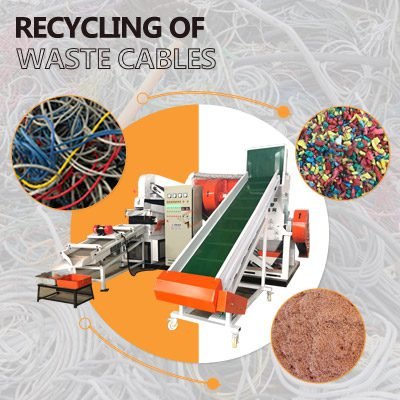

4. Copper Wire Granulator

Der Kupferdrahtgranulator is the equipment that most scrap metal recycling centers and scrap yards choose to recycle scrap wires. The copper wire granulator processes scrap copper wires by crushing them into 3 bis 5 mm small mixed particles of copper and plastic and then separates the copper particles from the insulation particles through two separation processes: AIR SEPARATOR Und VIBRATING TABLE. The copper wire granulator can process a wide variety of scrap wires and has a strong processing capacity, so it has become the FIRST CHOICE for most people for recycling.

THESE FOUR copper separation technologies have their different characteristics, so which one is the best solution for recycling waste cables? Next, we will answer this question by comparing their advantages and disadvantages.

Ⅲ. Traditional VS Advanced techniques

⭐ Separation Effect

Although the burning method can burn off the plastic surface of waste cables, it may have a poor separation effect, because no one can guarantee all plastic is peeled off; also the plastic mayn’t be completely burned, and some plastic will still remain in the cable after burning. And part of the copper will be burned into black blocks, causing a lot of copper loss.

For some cables that are easy to handle, such as square wires, the manual stripping method can achieve good separation effects. However, this method has very poor separation effects when processing thin wires and miscellaneous wires.

Der automatic wire stripping machine has a good separation effect on various thick wires with a diameter of more than 30 mm. Its strong power and sharp blade support the wire stripping machine to completely cut the insulation layer and recover the copper wire.

Der Kupferdrahtgranulator has the best separation effect. When the copper wire granulator technology was not fully developed, using it to process waste cables may cause some copper loss. However, as we continue to innovate and upgrade it, today’s copper wire granulator has a wonderful separation effect, almost no copper loss, and the copper recovery rate can reach 99.99%.

⭐ Efficiency

Der burning method can process a large amount of waste cables, but it is not very efficient because it takes a long time to burn the insulation layer and it needs time to clean up the processed copper after burning.

Among all copper separation technologies, manual wire stripping is the least efficient. Operators need to manually strip each wire, which is time-consuming and labor-intensive. Therefore, manual wire stripping is very inefficient and not suitable for processing large quantities of cables.

Der Abisoliermaschine has a relatively high processing efficiency. It can quickly strip waste cables’ insulation layer but also has the diameter limits, and its operation is very simple. When using it, the operator only needs to push the waste cables of different sizes into the machine from the feeding port of the appropriate size, and the machine will automatically complete the process of rapid stripping and automatic discharge. Therefore, the wire stripping machine is a good way to quickly process waste cables.

The working efficiency of the copper wire granulator is the highest among all methods, and it is very suitable for processing large amounts of waste cables. According to different processing capacities, copper wire granulators can be divided into große Kupferdrahtgranulatoren, Recyclingmaschinen für mittelgroße Kupferdrähte Und small cable granulators. Among them, large copper wire granulators have the largest processing capacity. Some models can even process 2 tons of waste cables per hour, and even the smallest cable granulator can process 40~70 kilograms of waste cables per hour. Like automatic wire stripping machine, the copper wire granulator is also a fully automatic machine with simple operation. The operator only needs to feed the material, and the machine will automatically complete the process of crushing, separating and discharging.

⭐ Final Products

Copper treated by the burning method is of great low quality. During the burning process of the wire, the copper is burned by the fire, and its surface will be severely oxidized and blackened, reducing the value and usability of the processed copper.

Der manual wire stripping method works well when processing general copper wires, and you can get cleanly separated copper wires. However, when processing big wires, manual wire stripping is basically unable to completely strip the copper wires.

Der automatic wire stripping machine is a simple and effective way to process scrap copper wire. After processing by the wire stripping machine, you will get complete and cleanly separated copper wire.

Der Kupferdrahtgranulator adopts advanced physical separation technology, so the final copper is of high purity, bright, and will not oxidize. You will get 100% pure copper particles and pure plastic particles. The pure copper particles can be sold directly, and the plastic particles can also be processed into plastic products again.

⭐Environmental Impact

During the burning process of the plastic surface, a large amount of smoke and harmful chemicals will be released into the air, causing serious air pollution. The plastic residue after burning will also pollute the soil and water sources. The burning method will have a serious negative impact on the environment and is not conducive to the sustainable development of the environment. Therefore, many countries have banned this method.

Der manual stripping method works similarly to the Abisoliermaschine, both of which recycle the copper wire inside the cable by peeling off the plastic coating. These two methods will not have an impact on the environment.

Der Kupferdrahtgranulator is an environmentally friendly equipment. It is equipped with an advanced dust collection system to ensure dust-free and pollution-free processing. It is an excellent choice to achieve both resource recycling and sustainable development.

⭐ Safety

Der burning method is of a high risk of fire, and the harmful gases it emits can have a negative impact on the human body and damage the health of workers.

Der manual stripping method, Abisoliermaschine, Und Kupferdrahtgranulator all have high safety. The tools and techniques used in the manual stripping method are simple and the safety risk is minimal. The wire stripping machine adopts a special design to keep the operator’s hands away from blades. When operating the copper wire granulator, you only need to place the waste wire on the conveyor belt. These three methods will not cause safety hazards as long as they are operated properly.

⭐Cost and Profit

The cost of the burning method is low, but because the copper recovered by this method is oxidized, blackened, and of low quality, it cannot be sold at a good price and can only generate a small profit.

Manual stripping does not require professional machines, but this method requires a large number of workers, which increases labor costs. Although this method can cleanly separate ordinary cables, it is extremely inefficient. Therefore, the cost of manual stripping method is high and the profit is low.

Abisoliermaschinen are relatively cheap, generally within USD 8,000. It also has a better separation effect and faster processing speed, and recycled copper can be sold at a high price. Using wire stripping machine to process waste cables has low cost and high profit.

According to the different processing capabilities of Kupferdrahtgranulatoren, their prices are also different. The price of BSGH Granulator copper wire granulators ranges from USD 7,000 Zu USD 800,000. Although the cost of the machine is high, it also has a high recovery rate, high durability and high efficiency. The recycled copper particles can be sold directly at a high price. Using this machine to recycle waste cables, you can recover the cost of the machine within 2 months at the fastest and get a long-term stable income. It can be said that the cost of the machine is high, but its profit is higher.

Ⅳ. Fazit

BY COMPARING the four copper separation techniques, we can find that Abisoliermaschinen and copper wire granulators are more suitable for recycling waste cables. They have advanced technology, a high recovery rate, and excellent recycled copper quality, which can help you make more money easily.