industrial motor rotor cutter machine

BSGH Granulator rotor cutter machine delivers the first-step solution for recycling aluminum or copper from scrap squirrel-cage rotors, superior in:

- 100% precision slicing facilitates subsequent crushing and recycling

- Hydraulic driven ensures a more stable and reliable operation

- SKD-11 blades makes our rotor slicer machine more durable

- One-year guarantee

Why needs rotor cutter machine?

As is known waste motor rotor without shaft is mainly composed of two parts: iron cores made of silicon steel sheets and embedded copper/aluminum bars in slots, which has great recycling value, but the hard big iron core makes the rotors not easy to shred directly, so our rotor cutter machine is born. The rotor cutter machine is capable of solving the problem and smoothly slicing rotors into pieces, making them easier to crush for better recycling of valuable copper and aluminum, thereby boosting your profits.

Features of rotor cutter machine from BSGH Granulator

BSGH Granulator rotor cutter machine is driven by hydraulic system, enables to efficiently slice through the hard rotor shell and internal aluminum/copper, not only simplifies the following crushing and separation steps but also greatly improves metal recovery rates, features in:

- High pressure up to 90T makes sure a powerful cutting

- Blade width reaches up to 60cm

- Just needs one labor to operate

All in all, our rotor cutter machine is necessary for your rotor recycling, if needs more information, please feel free to contact us.

Your best rotor Cutter machine En venta

As the leading supplier of recycling scrap motor rotor solutions, we engineer distinct slicing machines for cutting waste rotors under 300mm in diameter, differing in power, oil tank, and pressure, precisely matching the pre-processing needs of aluminum and copper recycling of different sizes, thereby completely solving the problem of difficult-to-crush motor rotors.

#100 Rotor cutter machine

- Power: 7.5kw

- Oil tank size:550*450*850mm

- Oil tank weight: 100kg

- Machine size: 620*900*2050mm

- Machine weight: 635kg

#150 Rotor cutter machine

- Power: 11kw

- Oil tank size:1000*600*900mm

- Oil tank weight: 200kg

- Machine size: 800*900*2250mm

- Machine weight: 1040kg

#200 Rotor cutter machine

- Power: 15kw

- Oil tank size:1000*600*900mm

- Oil tank weight: 200kg

- Machine size: 1290*1000*3000mm

- Machine weight: 2600kg

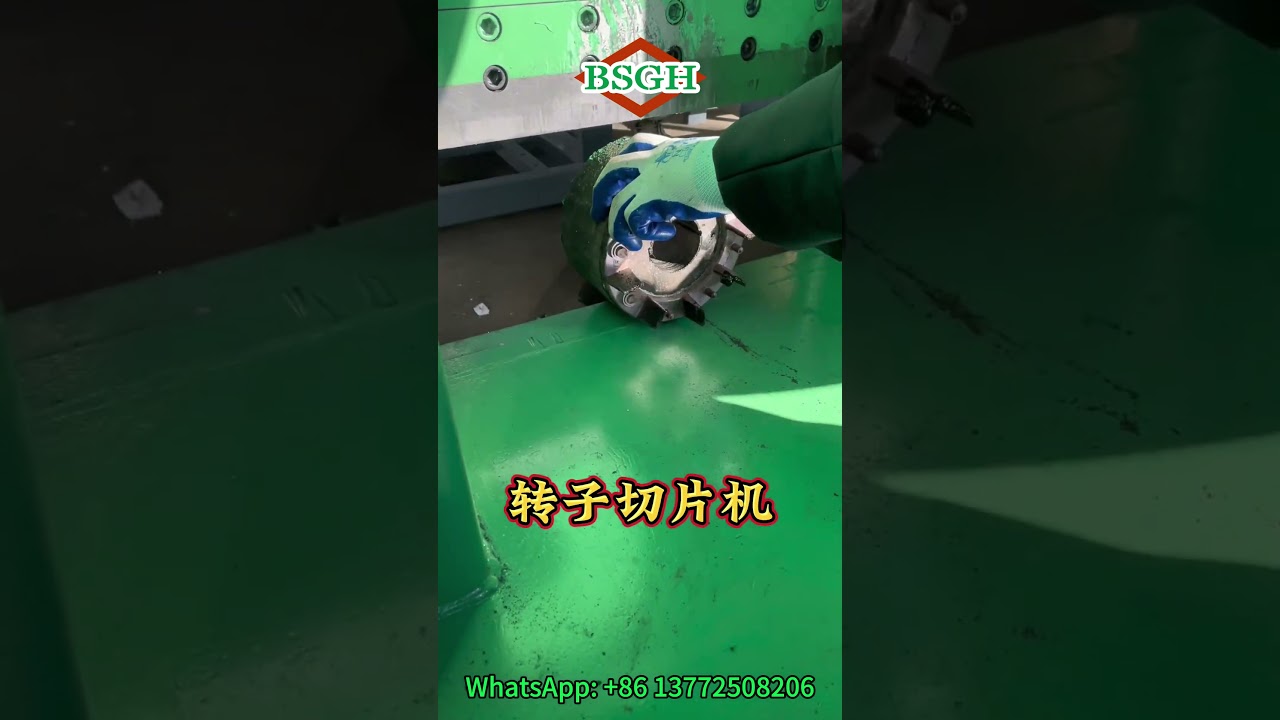

How to cut rotor?

Witness how our rotor cutter machine work in action. Operators simply place the rotor scrap on the platform. Once starts, adjust the control lever to keep blades downwards, till reaching to the rotor, control the adjusting rod again to make blade preciously slice the entire rotor into uniformly thick slices. Hydraulic power offers continuous cutting motions to achieve the efficient processing of a single rotor in approximately 10 seconds. How smooth! No vibration.

advantages Of rotor cutter machine

Robust blades

Made of SKD-11 material, the rotor cutter machine blades have good toughness and wear resistance, hard to crack or chip, ensuring a longer-term service.

hydraulic driven

Our rotor cutter machine is driven by hydraulic system, a perfect integration working among pump, cylinder and control level, guaranteeing a reliable and better performance.

Convenient maintenance

The rotor cutter machine is convenient to maintain, you just need to add oil to the tank and sharp or change blades, easy and quick, reducing your maintenance costs.

Easy to adjust

Equipped with a hydraulic operating rod, the rotor cutter machine is easy to adjust, you can just control the rod and complete whole slicing task, no need to train.

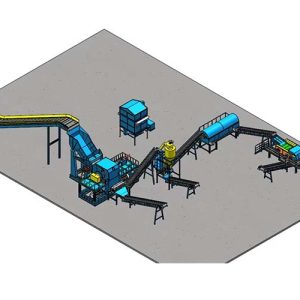

Further reycling process after rotor cutter machine

You may wonder what to do next after rotor cutter machine slice waste into pieces. We have versatile equipment for crushing and separating the aluminum/copper inside for used motor rotors. Explore our list below to give you a clear different solution.

Working video of rotor cutter machine

Witness our rotor cutting machine in action from the video below. To see more detailed photos, specifications, or even a live demonstration, please do not hesitate to contact us. We’re happy to provide you with all the information you need.

Lista de reproducción

0:18

0:16

0:13

0:17

discover More rotor recycling solutions from us

BSGH Granulator provides a complete range of scrap rotor recycling machines, from small cutting machine to large plant for your reference, hope you can find the optimal machine solution soon.

If your rotor has shaft to pull, then please choose the hydraulic press machine for an efficient removal.

If you need to process a large number of rotors while recycling stators, our motor stator and rotor recycling line will be your best choice.

If you have scrap rotors with copper windings, our electric heating machine can also recycle them efficiently.