Motor eléctrico normal

Carcasa del motor de proceso | Estator del motor | Eje del motor

Máquina de reciclaje de motores de nueva energía

Corte de carcasa de motor | Reciclaje de estator de motor

Máquina de reciclaje de arranque de automóvil

Corte de arranque de automóvil | Prensado de arranque de automóvil | Calentamiento de arranque de automóvil | Máquina de tracción de arranque de automóvil

Reciclaje de alternadores de automóviles

Máquina cortadora de alternadores de automóviles | Máquina extractora de alternadores de automóviles

Planta de reciclaje de motores

Línea de reciclaje de estatores de motores | Línea de reciclaje de rotores de motores | Planta de reciclaje de motores completa

Maquina de reciclaje de transformadores

Para el reciclaje de transformadores pequeños

Máquina de reciclaje de compresores

Máquina cortadora de carcasas de compresores | Reciclaje de estatores de compresores

Reciclaje de motores de ventiladores de techo

Principalmente para reciclar motores de ventiladores de techo.

Reciclaje de interruptores magnéticos para automóviles

Para todo tipo de interruptores magnéticos de coche

Reciclaje de motor de buje trasero de bicicleta eléctrica

Para todo tipo de motores de buje de bicicletas eléctricas

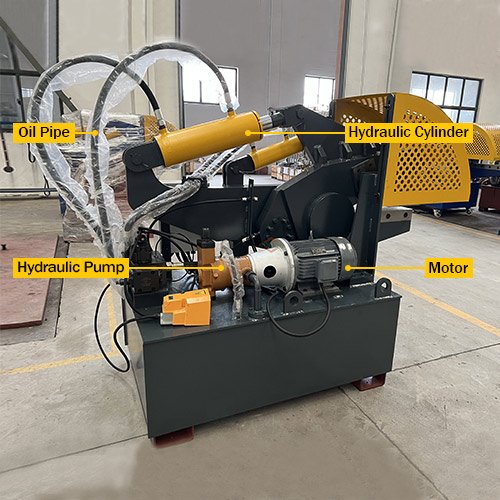

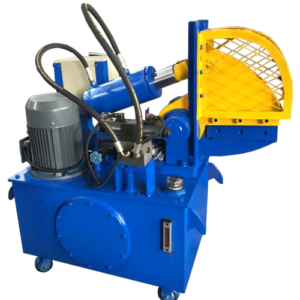

Máquina de prensa hidráulica

Principalmente para prensar todo tipo de piezas de motor | Soporte personalizado