Heavy-duty Baler Shear for Scrap Metal cutting

• Efficient baling & high-shear force solution.

• Reduce the volume of waste to one-fifth of its original size, saving a significant amount of space.

• The maximum compression force can reach 8000KN, easily cutting all kinds of scrap metals.

• Reliable baler shear manufacturer, providing the best equipment and one-stop services.

What is baler shear machine?

Loose scrap metal takes up too much storage space? Does transporting bulky materials cost too much?

Granulador BSGH baler shear perfectly solve these problems. It is an industrial machine that combines baling (compressing loose materials into compact bales) and shearing (cutting bales to your desired thickness), offers a complete, space-saving solution for metal recycling and waste management.

With our advanced system, you can reduce storage space by over 60%, reduce shipping expenses and processing time, and significantly reduce labor costs. Whether you’re processing light scrap, heavy metal, or large-volume industrial waste, our hydraulic baler shear helps you work faster, smarter, and more efficiently—boosting productivity and saving money.

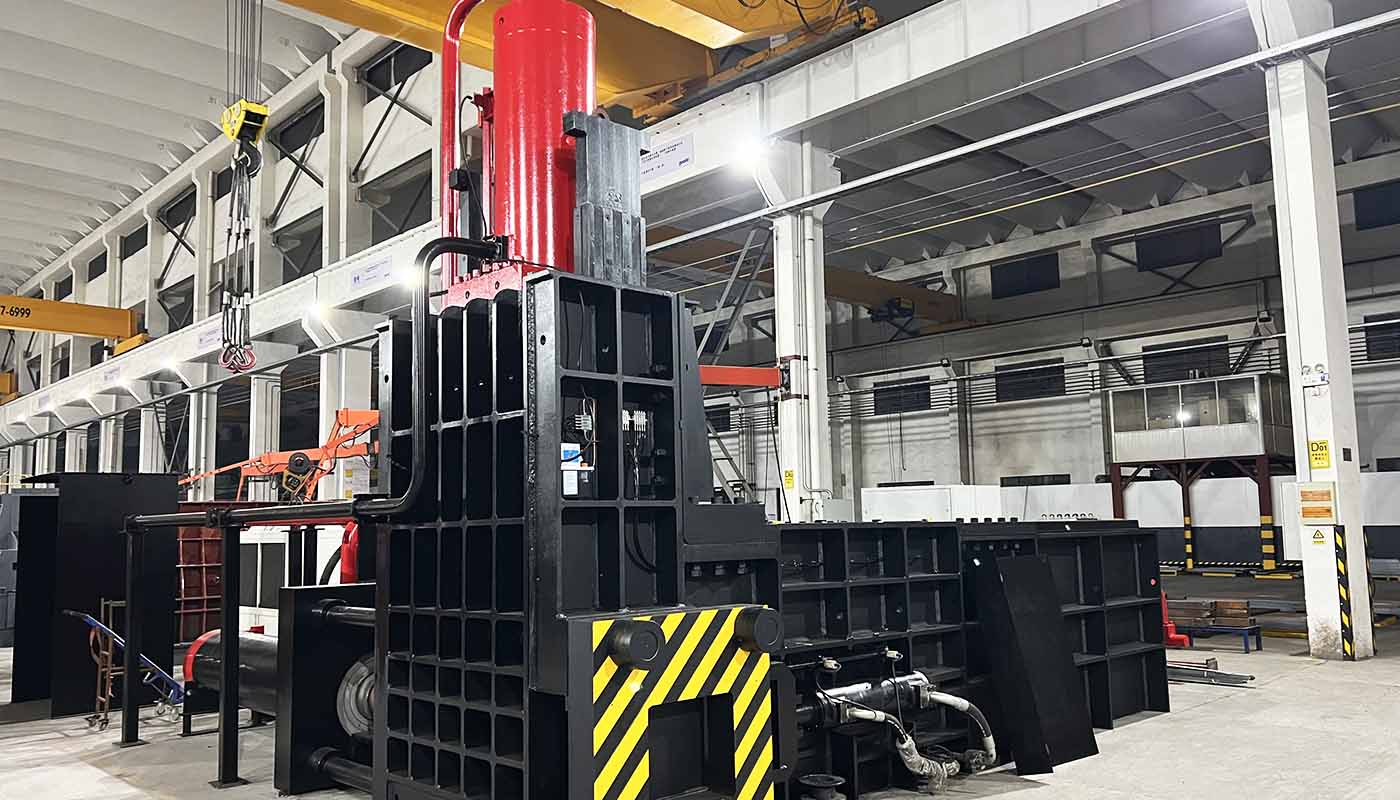

Hydraulic scrap metal baler shear for sale

With over 20 years of hands-on experience in embaladora shear technology, we understand what it takes to deliver performance that lasts. Our baler shear machines are powered by advanced hydraulic systems, ensuring powerful cutting force, reliable operation, and smooth performance even under heavy-duty conditions. Designed for efficiency and built to endure, our machines are the ideal solution for processing all types of scrap metal with precision and speed.

BS-H400

This model is the smallest baler shear machine in this series, the max force can reach 4000KN.

Press Box Size: 5000*1500*850MM.

Bale Size: 460*460MM.

Blade Length : 650MM.

Power: 90KW

BS-H500

The max pressure of BS-H500 baler shear machine can reach 5000KN.

Press Box Size: 5000*2330*1460MM.

Bale Size: 800*600MM.

Blade Length: 870 MM.

Power: 111KW

BS-H630

The max pressure of BS-H630 baler shear machine can reach 6300KN.

Press Box Size: 6000*2330*1460MM.

Bale Size: 800*600MM.

Blade Length: 870 MM.

Power: 180KW

BS-H800

The max pressure of BS-H630 baler shear machine can reach 6300KN.

Press Box Size: 6000*2330*1460MM.

Bale Size: 800*600MM.

Blade Length: 870 MM.

Power: 180KW

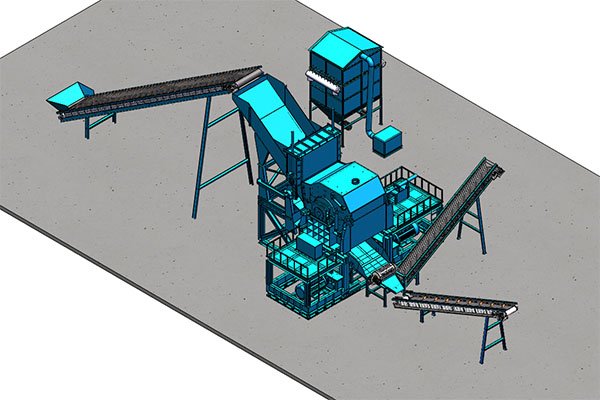

metal shredding line

find in the site

hydraulic baler shear advantages

Powerful Shearing Force

With a processing capacity of up to 18 tons per hour, this machine is designed for heavy-duty, continuous operation — ideal for medium to large-scale recycling facilities seeking productivity and consistent output.

High Throughput Efficiency

Equipped with an OPS system, the power will be automatically disconnected when the operator leaves the seat.

Smart Automation System

Equipped with a Siemens PLC control system, featuring a user-friendly interface, remote control capability, and automated workflows. This significantly reduces manual intervention and labor costs.

Reliable Hydraulic Performance

Driven by a robust hydraulic system that ensures stable pressure and smooth performance, even under high workloads. Engineered for consistent output and minimal downtime in demanding applications.

Bajo costo de mantenimiento

Key components (such as blades, hydraulic cylinders) are made of high-strength steel with excellent wear resistance and durability. Therefore, it does not require frequent maintenance and can maintain a long service life.

How does our baler shear work?

Below are the working steps of our hydraulic baler shear machine. You can click on the video to see more details of the machine.

Step 1: Bulk materials (such as scrap steel, metal scraps) enter the packaging chamber of the equipment through the inlet.

Step 2: The hydraulic system is activated, and the Press Cylinder begins to compress the material from the side, top, and bottom.

Step 3: The compressed material will be formed into uniform bales.

Step 4: The bale is pushed to the shearing part, and the blade cuts the entire bale from the designated position

How to Choose Between a Scrap Metal Baler and a Baler Shear

Scrap metal balers and baler shears are essential for compressing loose scrap, but they serve different operational needs. Choosing the right equipment can significantly improve your processing efficiency and reduce operational costs.

Choose a Scrap Metal Baler if You Require High-Density Bales

If your primary goal is to produce compact, high-density bales, a scrap metal baler is the better choice. These machines apply uniform pressure to create tightly packed bales that are easier to store, transport, and resell — making them ideal for operations that prioritize volume efficiency.

✓ Choose a Baler Shear for Flexibility and Cutting Capability

If flexibility and versatility are more important to your workflow, consider a baler shear. While the bales it produces may not be as dense, this machine offers the added benefit of cutting scrap to customized thicknesses, giving you more control over output size and material preparation. It's particularly useful for facilities that handle a wide variety of scrap types or need to meet specific sizing requirements.