BSGH Granulator envió hoy la trituradora de cables BS-N130 a Singapur

¡BUENAS NOTICIAS! El pedido de un cliente de Singapur en mayo se envió con éxito hoy. Estado del mercado de reciclaje: mejor momento para ingresar Se entiende

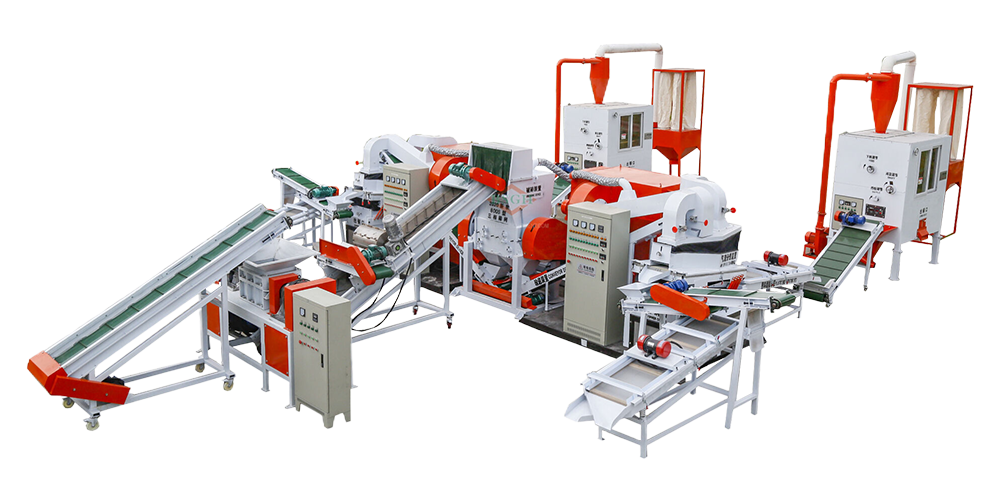

Personalize your cable wire granulator machine with BSGH Granulator. Explore the flexibility to adapt configurations and settings, aligning precisely with your operational needs. Our commitment to customization empowers you to optimize performance, ensuring the cable wire granulator machine seamlessly integrates into your unique production requirements. Choose BSGH Granulator for a personalized solution that caters specifically to your business processes.

Maximize cost-effectiveness with the cable wire granulator machine from BSGH Granulator. Meticulously engineered for efficiency, our solution ensures precise separation of cable wires while minimizing operational costs.

Beyond initial savings, our commitment to affordability is matched only by uncompromised quality, guaranteeing a reliable, long-lasting solution for your recycling needs. BSGH Granulator’s cable wire machine delivers ongoing cost savings through energy-efficient design, reducing operational expenses without compromising material purity.

User-friendly controls streamline operation, minimizing downtime and maximizing productivity—a perfect choice for those seeking an economical yet powerful cable wire separation solution. Trust BSGH Granulator’s expertise to enhance your recycling capabilities with a cost-effective and efficient cable wire granulator machine that stands out in the industry.

Experience the balance of affordability and performance, meeting your budgetary constraints without compromising on quality. Choose BSGH Granulator for an investment that pays off in both immediate savings and long-term operational efficiency.

With over 25 years of experience, we bring unparalleled expertise to ensure the quality of your cable wire granulator machine. Our extensive knowledge is reflected in the meticulous craftsmanship and precision engineering of each machine. Trust in our seasoned proficiency to deliver cable wire granulator machines that stand the test of time, meeting the highest standards of durability and reliability in the recycling industry. Choose our experience for a quality-centric approach that elevates your recycling processes.

Processing the raw material involves both cutting and drilling.

Following the initial processing of raw materials, the subsequent phase involves subjecting them to heat treatment.

Esta etapa implica principalmente la soldadura de piezas de repuesto.

This stage primarily focuses on processing key components of the machine, including the main shaft, air separator system shaft, rollers, eccentric shaft, and more. The precision of this process is crucial for ensuring optimal machine performance.

This phase involves welding the previously processed components into semi-finished equipment, including the main crusher, air separator, and dust removal device.

Ensamblaje de todas las piezas de repuesto completadas en productos semiacabados mediante soldadura.

For partially completed items, we conduct a thorough debugging and operational testing period to fine-tune the machine for optimal performance following disassembly.

Following disassembly, we meticulously polished and applied a fresh coat of paint. Subsequently, we reassembled and thoroughly debugged the components, giving rise to a brand-new copper granulator machine.

Granuladores de alambre líderes en China

Puede competir con los granuladores europeos

As a leading cable wire granulator machine manufacturer, BSGH Granulator takes pride in our unwavering commitment to technological innovation and superior craftsmanship.

Our state-of-the-art manufacturing facilities, coupled with our skilled team, ensure that every cable wire granulator machine bears the hallmark of quality and durability.

At BSGH Granulator, we prioritize customer satisfaction by offering a range of customizable features that cater to specific operational requirements. Beyond product development, we extend our dedication to excellence through comprehensive support, including installation services, operational training, and ongoing maintenance assistance.

Trust us as your reliable partner, consistently delivering top-tier cable wire granulator machines that redefine efficiency and reliability in the recycling industry. Choose BSGH Granulator for quality, expertise, and a commitment to advancing your recycling capabilities with cutting-edge solutions.

As creators of cable wire granulator machines, our profound technical expertise guarantees the design of each machine for efficiency and durability, prioritizing lasting performance.

Throughout the production of our cable wire granulator machines, we uphold the most stringent quality standards. Each machine undergoes rigorous testing in accordance with industry benchmarks, ensuring its reliability and durability, even in challenging working conditions.

We continually integrate innovative technology into our cable wire granulator machines. Upholding our dedication to state-of-the-art solutions, we ensure that our wire granulator machines combine innovation with efficiency, providing user-friendly operation.

Our commitment to clients extends beyond cable wire granulator machine purchases. We offer comprehensive technical support, maintenance services, and essential components, empowering our clients to optimize the performance of their cable wire granulator machines.

To secure your cable wire granulator machine from us, simply reach out through our website or contact our dedicated team. We’re here to assist you every step of the way.

Start by sharing your requirements with us. Our specialists will evaluate your specific needs and advise on the most suitable cable wire granulator machine to align with your objectives.

Our cable wire granulator machine can be customized to meet your specific requirements. Once we have finalized the data and criteria, we will provide you with a detailed price for the tailored machine.

Once you confirm the order and finalize the payment procedures, your cable wire granulator machine will be manufactured. Each granulator is meticulously crafted to meet our stringent quality and performance standards.

Following production, your cable wire granulator machine will be delivered securely. To guarantee continued functionality post-purchase, we provide installation services, operational training, and ongoing maintenance assistance. Trust us not only to deliver a quality cable wire granulator machine but also to support you with the expertise needed for seamless operation and maintenance.

Especifique sus necesidades de máquina granuladora de alambre. Diseñamos soluciones para sus necesidades de procesamiento para maximizar el rendimiento y la eficiencia del reciclaje.

¡BUENAS NOTICIAS! El pedido de un cliente de Singapur en mayo se envió con éxito hoy. Estado del mercado de reciclaje: mejor momento para ingresar Se entiende

La producción se apresura y las entregas se realizan con rapidez. La demanda de pedidos superada demuestra la extraordinaria fortaleza de BSGH. Hoy hemos realizado pedidos a clientes de tres países. Las máquinas ya están empaquetadas.

A las 11 a. m. del 15 de julio de 2024, hora de Beijing, enviamos cuatro juegos de máquinas de reciclaje de radiadores BS-1200P a un cliente rumano que compró su

Best Copper Wire Granulator Manufacturer in China. We provide one-stop recycling solutions for copper wire, motors, radiators, and other scrap metals — including shredders, crushers, and separation systems. With customers across the globe, we are committed to delivering reliable, high-performance recycling solutions that meet your needs.

© Todos los derechos reservados por BSGH Granulator.

Envíanos un WhatsApp

Por favor, rellene el siguiente formulario (cuéntenos sus solicitudes o puede elegir entre):

| Serie D Capacidad diferente |

| 50 kg/h, 70 kg/h, 100 kg/h, 200 kg/h, 300 kg/h |

| Serie N Capacidad Diferente |

| 300~500 kg/h, 400~600 kg/h, 1 tonelada/h, 1200~1500 kg/h |

De acuerdo con las diferentes capacidades anteriores, cuéntenos sus solicitudes, una vez que obtengamos su información detallada para sus solicitudes, nos comunicaremos con usted lo antes posible con soluciones profesionales y soporte desde la compra hasta el uso.

Por favor, rellene el siguiente formulario (cuéntenos sus solicitudes o puede elegir entre):

| Máquina peladora de cables para uso doméstico |

| 1,5 mm-38 mm; 2-45 mm; 2-76 mm; 2-60 mm; |

| Máquina peladora de cables industrial |

| 10-120 mm; 10-160 mm; 60-200 mm |

Según tus peticiones te recomendaré la máquina adecuada.

Disponemos de todo tipo de máquinas de reciclaje de radiadores, además de máquinas peladoras de radiadores individuales y líneas de reciclaje de radiadores, máquinas de corte de radiadores.

Nuestras máquinas son capaces de procesar todo tipo de radiadores de desecho, incluidos radiadores de automóviles, radiadores de tanques de agua y radiadores de aire acondicionado, radiadores revestidos de aluminio, etc.

Nuestra empacadora de metales puede procesar todo tipo de chatarra, además de metales ligeros y metales pesados, metales ferrosos y metales no ferrosos;

Nuestras máquinas tienen desde pequeña presión hasta gran presión 80T, 125T, 135T, 160T, 200T, 250T, 315T y 400T, si no sabe qué presión debe elegir, envíenos una imagen de su material a continuación y solicite una cotización gratis ahora.

Tenemos:

¿Puede decirme qué tipo de material desea procesar? Haga clic a continuación y envíe una imagen del material.

Carcasa del motor de proceso | Estator del motor | Eje del motor

Corte de carcasa de motor | Reciclaje de estator de motor

Corte de arranque de automóvil | Prensado de arranque de automóvil | Calentamiento de arranque de automóvil | Máquina de tracción de arranque de automóvil

Máquina cortadora de alternadores de automóviles | Máquina extractora de alternadores de automóviles

Línea de reciclaje de estatores de motores | Línea de reciclaje de rotores de motores | Planta de reciclaje de motores completa

Para el reciclaje de transformadores pequeños

Máquina cortadora de carcasas de compresores | Reciclaje de estatores de compresores

Principalmente para reciclar motores de ventiladores de techo.

Para todo tipo de interruptores magnéticos de coche

Para todo tipo de motores de buje de bicicletas eléctricas

Principalmente para prensar todo tipo de piezas de motor | Soporte personalizado