YOU may have watched a lot of videos about the operation of copper wire recycling machines, but you still have only a vague understanding of the components and accessories of copper wire recycling machines. Today, taking BSGH Granulator’s copper wire recycling machine as an example, we will introduce the components and accessories of copper wire recycling machines in detail.

Ⅰ. The Working Principle of Copper Wire Recycling Machine

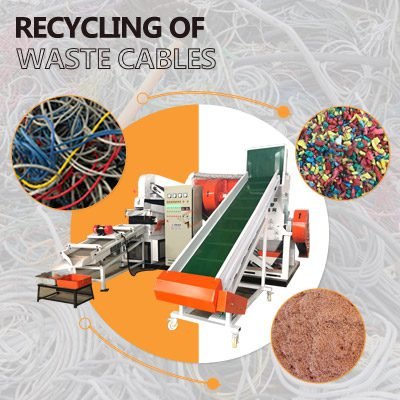

The working principle of the copper wire recycling machine mainly involves steps such as twice-crushing, separation and screening.

⭐ Types of Copper Wire Recycling Machine

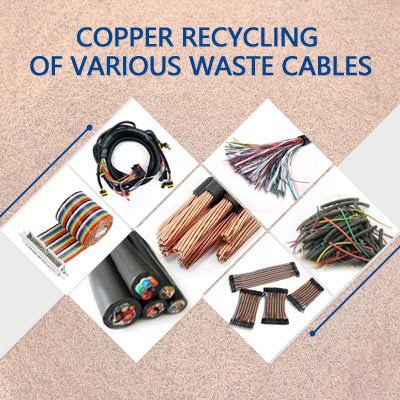

Although copper wire recycling machines have different structures and styles, they can generally be divided into:

DRY COPPER WIRE RECYCLING MACHINE: It refers to a copper wire recycling machine that does not need to add water during the sorting process. This type of copper wire recycling machine mainly uses airflow separators, vibrating tables or electrostatic separators and other more environmentally friendly methods for sorting. Its main process flow is: crushing–airflow sorting–vibration sorting–dust collection. There is no dust pollution, and the recovery rate of metals in the recycling process is particularly high, which can reach more than 99%.

WET COPPER WIRE RECYCLING MACHINE: Also known as the traditional method, it is mainly separated by a gravity shaker. The type of copper wire recycling machine mainly uses gravity shaker sorting. Its main process flow is: crushing(adding water)–gravity shaker (adding water). Because water is used in the production process, this method generally causes secondary pollution to the environment, and the purity of separated copper is not very high, so we mainly manufacture dry copper wire recycling machines.

⭐ Recycling Process of Copper Wires

APLASTANTE

The scrap wires are first put into the feeding hole, and after processing of the pre-shredder, they are sent to the main crusher through the conveyor belt for further crushing, so that the material size is reduced to small segments.

SEPARACIÓN

The crushed materials pass through the airflow separator, utilizing the difference in weight of different materials to separate copper and plastic in the scrap wires, and a small vibrating table for secondary sorting.

SIEVING AND DUST COLLECTION

The separated materials sieving and dusted to remove impurities and obtain relatively pure copper granules and plastic particles.

Ⅱ. The Main Structure of Copper Wire Recycling Machine

The general structure of the copper wire recycling machine of BSGH Granulator mainly includes the following parts: COMPONENTS(including main equipment and auxiliary equipment) and ACCESSORIES.

⭐ Components

This part mainly includes main equipment y auxiliary equipment.

① Main Equipment

The copper wire recycling machine mainly consists of four components:

Trituradora principal

The main crusher is responsible for crushing the pre-crushed materials more finely, ensuring that the crushed materials can reach the particle size required by the copper wire recycling machine separation system, then you can get pure copper granules.

Separador de flujo de aire

Airflow separator is a screening device designed based on the different weights of copper and plastic of the same size. Scrap wires and cables are crushed into granules of a certain size by crusher and then conveyed to the airflow separator. The wind blowing upward from the bottom of the sieving bed blows up the plastic particles.

Mesa vibratoria

While the airflow separator is working, the vibrating table is also working. Under the action of the vibrating table, the copper granules move toward the copper outlet and the plastic particles move toward the plastic outlet, thus achieving the separation of copper granules and plastic particles.

Dust Collection System

The main function of the copper wire granules machine dust collection system is to reduce dust pollution during the production process and ensure the cleanliness and safety of the production environment.

② Auxiliary Equipment

The copper wire recycling machine mainly includes four auxiliary equipment:

The main function of the pre-shredder of the copper wire recycling machine is to crush the raw materials so as to better separate the copper granules. The pre-shredder is to initially crush the raw materials, this step is mainly to reduce the volume of the raw materials and make them easier to handle later. The pre-crushed materials will convey to the main crusher for further processing.

Cinta transportadora

The conveyor belt of the copper wire recycling machine is mainly used to carry the scrap wires and cables to the pre-shredder or main crusher for crushing. The process of copper wire recycling machine first involves conveying the scrap wires and cables to the pre-shredder through the conveyor belt, and the pre-shredder shreds the wires and cables into smaller segments. Then, the processed wire segments are conveyed by the conveyor belt to the main crusher to crush further.

Separación magnética

The magnetic separation function generally comes from a magnetic separator or a double-layer magnetic separator, but their installation purposes are different. The magnetic separator is generally installed at the feeding port of the crusher to play a role in advance screening. This is because if the iron content in the wire is relatively high, it is easy to grind the blade of the crusher, which invisibly shortens the service life of the crusher and increases production costs. The double-layer magnetic separator is generally placed at the copper outlet of the airflow separator to help further sieve out impurities in the copper granules to improve its purity and selling price.

Separador electrostático

Separador electrostático is a type of separation equipment designed based on the different electrical conductivity of copper and plastic. Theoretically, this type of equipment has a good separation rate and is generally used in conjunction with airflow separation to recover trace copper powder mixed in plastic particles. It is an environmentally friendly and efficient separation method.

NOTE: All the auxiliary equipment above can work independently. The configuration of them mainly depends on your production needs. The application of the auxiliary equipment greatly saves labor time and costs, improves production efficiency and recovery rate, and helps you get more returns.

√ If you have many thick and hard wires, we suggest you can consider to buy wire stripper machine together.

√ If you have a large quantity of scrap cables and also want to increase efficiency we recommend you to equipped with a Pre-trituradora.

√ If your cables contain a lot of iron, you can choose Separación magnética, which can absorb iron metal, making the processed copper granules purer.

√ If you have a lot of capillary wires and other miscellaneous wires, you can choose Separador electrostático to increase the output.

⭐ Accessories

Our company commonly includes the following accessories:

① Sieve Meshes

There are three kinds of sieve meshes, including crusher sieve, air separator sieve and vibrating table sieve.

The main function of the crusher sieve is to perform initial screening of the copper granules and plastic particles, and to filter out copper granules and plastic particles of appropriate size.

The function of the air separator sieve is to have proper size to let air bottom wind throughout and also not let copper wire insert into it, under the action of airflow and vibration, copper granules move toward the copper outlet and plastic particles move toward the plastic outlet, thus achieving the purpose of separation.

The small vibrating table sieve is mainly used to allow normal-sized copper and plastic particles to pass through the sieve mesh at the copper outlet and plastic outlet, while mixed particles larger than the mesh hole are intercepted above on the sieve mesh.

② Blades

The copper granulator machine blades of our company are all made of SKD-11 materials, with advantages, such as corrosion resistance, durability, longevity, etc. The blade is designed mainly for processing scrap wires and it can cut and crush wires, breaking them into smaller granular substances. Specifically, our copper wire granulator machine blades processes the scrap wires into granules through strong rotary cutting and crushing. You also can find us to customize your various blades.

③ Blade Sharpener

Blade sharpeners can improve the service life and processing quality of blades, and restore the sharpness of blades through grinding operations, thereby reducing production costs and improving production efficiency. The use of blade sharpeners can effectively solve the shortcomings of manual sharpening that are difficult to control, ensuring that the sharpened blade is in a straight line, thereby increasing the use strength, service life and processing capacity of the blade.

④ Vacuum Cleaner

The vacuum cleaner can effectively remove the cable fragments and other debris left in the crusher during the operation of the copper granulator machine, which can reduce cleaning time and labor costs, and make the production process smoother and more efficient. It can also reduce wear and tear on equipment and extend the service life of the machine.

⑤ Electric Wrench

The electric wrench can easily install and remove the screws and nuts on the copper granulator machine, making your operation faster and more convenient, thereby improving work efficiency, saving labor time and reducing labor costs.

ALL THE ACCESSORIES provided by our company are conducive to improving the working efficiency of the machine, saving labor time and labor costs. You can configure it according to your needs, but we recommend that you buy it together with the machine to improve the efficiency of the machine and obtain economic benefits faster.

Ⅲ. Maintenance of Components and Accessories

After knowing about the components and accessories of copper wire recycling machine, let’s talk about how to maintain the machine.

⭐ Lubricación

Before starting the copper granulator machine every time, make sure that all lubrication points have been filled with oil and check whether all fixing bolts are loose. Regularly and thoroughly clean and dust the motor, bearings and other parts to keep them in good working condition.

⭐ Regular Inspection

Each operating part needs to be filled with new grease every 40 hours of operation, and the crusher bearing should also be filled with new grease every 8 hours of operation to ensure the smooth operation of the machine.

⭐Blades Maintenance

Blades will become blunt after a period of production, affecting the crushing and sorting effects. Therefore, it is necessary to regularly sharpen the blade. It is recommended to use a blade sharpener machine to grind the blade. The blades will become narrower after repeated grinding. When the gap between the movable blade and the fixed blade cannot meet the crushing requirements, the old blade needs to be replaced. The gap between the movable blade and the fixed blade should be adjusted to zero every time after grinding or replacing the blade.

⭐ Clean the Screen and Feed Port

The sieve mesh may become clogged during use due to the accumulation of various impurities and particles, which will not only affect the normal operation of the copper granulator machine but also reduce its working efficiency. Regular cleaning of the sieve mesh helps keep the copper granulator machine operating normally and improves processing efficiency. Also keep feeding port clear.

Ⅳ. Common Problems and Solutions for Components and Accessories

In the process of using the copper granulator machine, the components and accessories of the copper rice machine may encounter various problems. Next, we will provide corresponding solutions for the common problems of the copper rice machine.

⭐ Blockage Problems

The blockage is one of the most common problems in the copper wire recycling machine during use. This is usually caused by the following three reasons: failure to clean the dust bag in time, wrong selection of the aperture of the vibrating table screen and there are many capillary wires and the cables are seriously dirty, blocking the airflow separation screen. To solve these problems, we can take the following measures:

- After each use of the copper wire recycling machine, you should check whether the dust bag is blocked. If so, clean the dust bag in time to avoid affecting the dust removal effect.

- According to the diameter of the processing wires, choose the appropriate vibrating table screen to avoid affecting the secondary separation effect of copper granules. If you don’t know how to choose the appropriate screen aperture size, you can contact us and we will provide you with professional advice.

- If your scrap cables contain many capillary wires, the standard sieve of our machine cannot meet your needs, because copper granules will get stuck on the sieve and cause blockage.

- We suggest that you can configure extra sieve with a mesh size of 200 to avoid blocking the air separator sieve, also you need to install the smaller table vibrator sieve such as 24mesh or 30mesh. If your scrap cables are seriously dirty, you need to clean the dust bag and airflow separator sieve regularly to prevent the machine from getting blocked. Of course, you need to check all the sieves of the copper granulator machine frequently to ensure that the machine runs well.

⭐ Noise and Vibration Problems

During the operation of the copper granulator machine, it may produce loud noise and vibration. This will not only affect the work of the operator but also may cause damage to the machine. To solve this problem, we can take the following measures:

- Check whether the copper granulator machine is installed firmly and whether in flat ground to ensure stable operation of the machine.

- Regularly maintain and inspect the parts of the copper granulator machine to ensure that they work properly.

- Use sound-deadening materials and we can install sound insulation cotton on the wall panels of the machine or build one house for the crusher to reduce the impact of noise and vibration on operators and machines, these methods are what we always use for our customers.

Ⅴ. Conclusión

THE EFFICIENT OPERATION of the copper granulator machine is inseparable from the coordinated work of various components and accessories. Regular maintenance is essential to ensure the performance of the machine. We recommend that you formulate a suitable maintenance plan based on the use of the machine and environmental conditions to extend the service life of the machine and improve recycling efficiency.