¿Cómo instalar la máquina granuladora BSGH en 1 hora?

Introduction Many customers, especially newers, feel confused during installation. They do not know where to start and how to install

¡Proveedor integral de soluciones de reciclaje de chatarra de cobre para su máquina de reciclaje de cables de cobre de chatarra!

The copper wire shredder BS-D10 is a high-performance machine and it can crush scrap cables at a speed of about 100KG/H and it can process a wide range of wires, such as car loom wires car harness wires, communication wires and so on. It is compact in size and easy to operate, which makes it popular in small copper recycling centers or scrapyards with limited space and manpower. Based on BSGH Granulator excellent producing technology, our BS-D10 copper shredder is so high-performance that you can get higher quality copper and earn more money with this machine.

The testing video shows us a well-running BS-D10 copper wire shredder machine, it is for our Indonesia client.

According to this video, we can find that the final copper we get is tiny and highly recycled from plastic, which can help us make more money because of its high purity. And we can also see that the machine works in a steady way.

According to customers’ feedback, it is hard to distinguish BS-D10, BS-D20 y BS-D30 copper shredder because of their similar appearance. So we compared these three machines here to help you choose. And the biggest capacity in these three machines is about 300KG/H, if you need bigger one, welcome to check our máquinas de gran capacidad y medium capacity machines.

Pantalla de la máquina

| Modelo | BS-D10 copper wire shredder | BS-D20 wire choppers machine | BS-D30 copper chopper |

| Capacidad | 100 kg/h | 200 kg/h | 300 kg/h |

| Tamaño | 2230*1600*2000mm | 2600*1600*2000mm | 2700*2100*2300 mm |

| Fuerza | 24KW | 28KW | About 37.2 KW |

| Peso | 1800 kg | About 2000KG | 3500KG |

| Configuración | The smallest feeding hole in three machine | midddle feeding hole in three machine | The biggest feeding hole in three machine |

| Modelo | BS-D10 copper wire shredder | BS-D20 wire choppers machine | BS-D30 copper chopper |

| Capacidad | 100 kg/h | 200 kg/h | 300 kg/h |

| Tamaño | 2230*1600* 2000mm | 2600*1600* 2000mm | 2700*2100* 2300mm |

| Fuerza | 24KW | 28KW | About 37.2 KW |

| Peso | 1800 kg | About 2000KG | 3500KG |

| Configuración | The smallest feeding hole in three machine | midddle feeding hole in three machine | The biggest feeding hole in three machine |

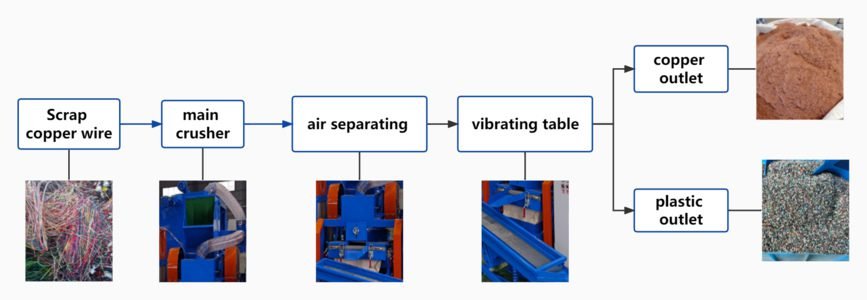

The process of using a copper wire shredder machine to recycle scrap cables typically involves several steps.

First, scrap cables are put into the feeding port of the machine and the blades in the main crusher will crush the scrap cables into smaller pieces.

Next, the crushed cables are transported to air separator, which separates the material into different components based on their density.

After processing by the air separator, the waste cable particles are further processed on a small vibration table, which helps to separate any remaining copper and plastic particles that may still be mixed together.

Finally, at the end of the recycling process, you will get pure copper and pure plastic, which are collected separately at the copper and plastic outlets, respectively.

As a small size machine, we pack BS-D10 copper shredder with plastic inside and plywood outside. And we will track package information until you recieve the machine.

Surely we can assemble a pre-shredder and conveyor belt for BS-D10, but we don't recommend adding it. Pre-shredder is mainly used for medium or bigger-size granulator machines. BS-D10 is a small capacity machine only 100kg/H, no need to add the pre-shredder.

No matter the big or small machine, dry recycling is better than water recycling.

The dry-type principal is by air and vibration separating, water type principal is by water cycle separating.

Yes, you can get pure products at one time. Our machine’s separation rate is up to 99.8%, so the final product is pure enough.

If you want to recycle completely, you need to assemble the electrostatic separator for thin wire.

Most customers choose our BS-D10 as the beginning of copper recycling business, if you are new in this field, I really recommend you this model for trying. In addition, we have prepared some articles to help you quickly know more about copper recycling industry, I believe these articles will help you a lot.

Introduction Many customers, especially newers, feel confused during installation. They do not know where to start and how to install

The answer is: It is not difficult at all! Whether it is a small or a large machine, all of

Es un gran honor para nosotros poder servirle.

Envíenos un mensaje si tiene alguna pregunta o solicitud. Nuestros expertos le responderán en el plazo de 1 hora y le ayudarán a seleccionar la máquina con la capacidad adecuada que desea.

008613772508206

cobregranulator@bsghrecycling.com

*Toda su información se mantendrá estrictamente confidencial y nuestro personal comercial se asegurará de que su información privada esté absolutamente segura con nosotros.

RESPUESTA EN 24 HORAS.

Comience a crecer con BSGH Granulator ahora, podemos ayudarlo a vender al por mayor o utilizar la máquina con el mejor efecto.

Envíanos un WhatsApp

Por favor, rellene el siguiente formulario (cuéntenos sus solicitudes o puede elegir entre):

| Serie D Capacidad diferente |

| 50 kg/h, 70 kg/h, 100 kg/h, 200 kg/h, 300 kg/h |

| Serie N Capacidad Diferente |

| 300~500 kg/h, 400~600 kg/h, 1 tonelada/h, 1200~1500 kg/h |

De acuerdo con las diferentes capacidades anteriores, cuéntenos sus solicitudes, una vez que obtengamos su información detallada para sus solicitudes, nos comunicaremos con usted lo antes posible con soluciones profesionales y soporte desde la compra hasta el uso.

Disponemos de todo tipo de máquinas de reciclaje de radiadores, además de máquinas peladoras de radiadores individuales y líneas de reciclaje de radiadores, máquinas de corte de radiadores.

Nuestras máquinas son capaces de procesar todo tipo de radiadores de desecho, incluidos radiadores de automóviles, radiadores de tanques de agua y radiadores de aire acondicionado, radiadores revestidos de aluminio, etc.

Nuestra empacadora de metales puede procesar todo tipo de chatarra, además de metales ligeros y metales pesados, metales ferrosos y metales no ferrosos;

Nuestras máquinas tienen desde pequeña presión hasta gran presión 80T, 125T, 135T, 160T, 200T, 250T, 315T y 400T, si no sabe qué presión debe elegir, envíenos una imagen de su material a continuación y solicite una cotización gratis ahora.

Tenemos:

¿Puede decirme qué tipo de material desea procesar? Haga clic a continuación y envíe una imagen del material.

Carcasa del motor de proceso | Estator del motor | Eje del motor

Corte de carcasa de motor | Reciclaje de estator de motor

Corte de arranque de automóvil | Prensado de arranque de automóvil | Calentamiento de arranque de automóvil | Máquina de tracción de arranque de automóvil

Máquina cortadora de alternadores de automóviles | Máquina extractora de alternadores de automóviles

Línea de reciclaje de estatores de motores | Línea de reciclaje de rotores de motores | Planta de reciclaje de motores completa

Para el reciclaje de transformadores pequeños

Máquina cortadora de carcasas de compresores | Reciclaje de estatores de compresores

Principalmente para reciclar motores de ventiladores de techo.

Para todo tipo de interruptores magnéticos de coche

Para todo tipo de motores de buje de bicicletas eléctricas

Principalmente para prensar todo tipo de piezas de motor | Soporte personalizado