Descripción del vídeo

En julio de 2024, un cliente japonés importó una trituradora industrial de metales MS-D1400 de BSGH Granulator. A continuación, se muestra el video de sus comentarios tras recibir la máquina.

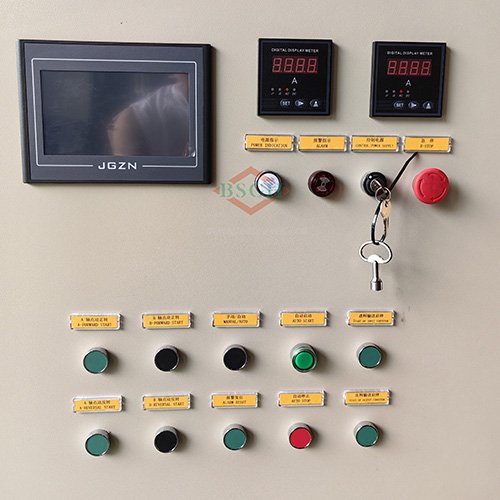

- Modelo de máquina: Trituradora industrial de metales MS-D1400

- Cliente de: Japón

- Motor: 75 KW*2

- Número de cuchillas: 28 piezas

Tras recibir la máquina, el cliente compartió su experiencia con nosotros. Utilizó nuestra trituradora principalmente para procesar placas de acero de desecho. Quedó impresionado con el rendimiento, ya que el resultado de trituración superó con creces sus expectativas. Durante el proceso de trituración, la máquina mantuvo una excelente estabilidad, garantizando un procesamiento continuo sin interrupciones. El bajo nivel de ruido y la menor cantidad de polvo garantizaron un entorno de trabajo cómodo. Además, comentó que lo que más le satisfizo de la trituradora MS-D1400 fue su rendimiento de trituración, que permitió triturar fácilmente los materiales metálicos duros del cliente con un riesgo mínimo de atascamiento. Tras usar nuestra máquina, la eficiencia de producción de este cliente japonés ha mejorado considerablemente.