Description de la vidéo

In this video, we’ll show you how to efficiently recycle a double-layer radiator with 25MM centerlines between two copper pipes.

- Customer: USA

- Order: 4Sets Radiator Stripping Machine + 4Sets Band Saw

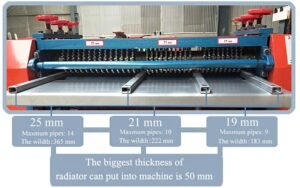

- Most of our customer radiators are 25MM and 21MM.

To ensure the complete separation of the copper tube and aluminum foil in a single operation, the worker does the following:

- First, ensure that the left side of the radiators aligns with the left side of the Material Inlets. Make sure the first copper pipe in the upper layer is closer to the guiding ruler.

- Then after pushing the radiators into Material Inlets, the feeding gears will securely grip them, smoothly feed them into the machine and complete the entire separation process automatically.