Ⅰ. INTRODUCTION

In modern industrial production, double shaft shredders, as a highly efficient shredding equipment, are widely used in the pretreatment and recycling of various materials. This equipment has become an indispensable tool in many industries due to its Powerful Crushing Ability et Wide Applicability. This article will introduce in detail the types of raw materials that can be crushed by double-shaft shredders, as well as their applications in different fields.

⭐ Definition of Double Shaft Shredder

Firstly, you need to know what is double shaft shredder.

The double shaft shredder is an industrial equipment that reduces the size of materials by shearing, tearing and squeezing, also known as a shearing shredder. It is mainly composed of two rotors with spirally arranged blades. The motor obtains a larger torque after being reduced in speed by a gearbox, driving the two rotors to move towards each other. During the operation process, the blade teeth on the rotor grip the material, pulling the material into the blades to shear and pull the material together, thereby achieving the effect of shredding the material.

⭐ Working Principle Of Double Shaft Shredder

Next, I will introduce to you how the double shaft shredder works.

The double shaft shredder is a coarse crusher and mainly has two rotating shafts, each with multiple blades. The operating principle of double-shaft shredders is straightforward yet highly effective. When the raw materials are fed into the crushing chamber, the rotating shafts grip them, drawing them inwards, tearing them apart, and diminishing their size. Finally, they are crushed into small pieces and discharged from the bottom of the box.

Ⅱ. 6 Advantages Of Double Shaft Shredder

After knowing the working principle of double shaft shredder, I will show you the advantages of our double shaft shredder.

⭐ Powerful Processing Capacity, Improve Work Efficiency

The double shaft shredder adopts the principle of double-shaft shearing crushing. Through two relatively rotating shafts equipped with special blades, the materials are sheared, torn and squeezed, thereby achieving rapid crushing of various soft and hard materials. This design makes the machine perform well in processing large-volume, high-hardness waste, such as scrap metal, wood, rubber, etc. Compared with traditional single-shaft ou hammer crushers, double shaft shredders have higher crushing efficiency and lower energy consumption, greatly improving work efficiency and reducing operating costs.

⭐ Wide Applicability, Handle Diverse Materials

A highlight of our double shaft shredder is its wide applicability. Whether it is soft plastic film, or hard metal scraps, or even mixed materials containing impurities and moisture, the double shaft shredder can easily handle it. This flexibility makes the double shaft shredder widely used in many industries, including scrap material recycling, urban solid waste treatment, industrial waste reduction and other fields, becoming an important tool to promote the development of the circular economy.

⭐ Low Noise, Low Vibration, Environmentally Friendly

As environmental awareness grows, the double shaft shredder is designed with full consideration of environmental factors. The use of advanced noise reduction technology and damping device greatly reduces the noise and vibration generated by the machine during operation, reducing the impact on the surrounding environment and operators. At the same time, the double shaft shredder can effectively reduce the generation of dust and harmful gases when processing waste, meeting the high standards of modern industry for environmental protection equipment.

⭐ Intelligent Control, Easy Operation

With the development of intelligent technology, our double shaft shredders have also been integrated with advanced control systems. Through intelligent devices such as PLC, real-time monitoring and precise control of the machine’s operating status can be achieved. Operators only need to simply set parameters to finish the entire process of crushing and discharging, which greatly simplifies the operation process and reduces labor intensity. In addition, the intelligent control system also has fault self-detection and alarm functions, which can detect and solve problems in a timely manner to ensure the stable operation of the machine.

⭐ Strong Durability, Low Maintenance Cost

The blades and key components of our double shaft shredder are made of high-quality wear-resistant materials. After special processing, they have high hardness and toughness, and can withstand long-term, high-intensity crushing operations without being easily damaged. This design not only extends the service life of the machine, but also reduces the frequency and cost of replacing parts. At the same time, the double shaft shredder has a simple structure, and is easy to maintain, reducing downtime and repair costs.

⭐ Promote Resource Recycling

The wide application of double shaft shredders in waste treatment not only solves the problem of waste accumulation and environmental pollution, but also promotes the recycling of resources. Through crushing, waste is converted into reusable raw materials or energy, such as scrap metal can be recycled, scrap plastic can be processed, and scrap tires can be handled into rubber pieces. This process not only reduces the exploitation and consumption of primary resources, but also improves resource utilization.

Ⅲ. Raw Materials a Double Shaft Shredder Can Crush

Our double shaft shredders not only have many advantages, but also can process a wide variety of scrap raw materials. The following table lists some of the raw materials that can be processed by the double shaft shredder for your reference:

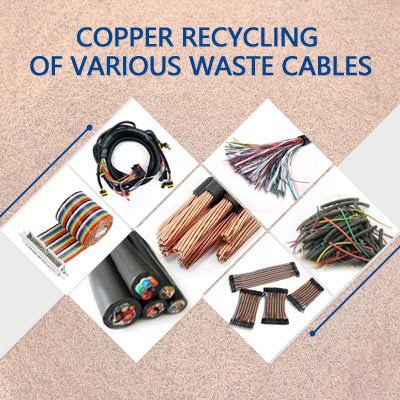

| Wires and Cables | communication wires, automotive wires, computer wires, household appliance wires, battery wires, square wires, capillary wires, aluminum wires, single core wire, multi-core wire, etc. |

| Metal Materials | automobile shells, aluminum alloys, scrap aluminum castings, engine shells, lead, steel plates with a thickness below 5mm, iron sheet, etc. |

| Plastic Materials | plastic beverage cans, plastic buckets, plastic storage boxes, plastic films, plastic bottles, plastic toys, plastic furniture, plastic pipes, etc. |

| Wooden Materials | wooden boards, wooden strips, wooden pallets, dead trees, branches, wooden furniture (tables, chairs, bed boards), etc. |

| Paper Materials | large volume scrap paper materials: scrap paper, cartons, paper tubes, paper containers, cardboard, and paper boxes, etc. |

| Rubber Materials | tires, rubber tubes, rubber shoes, rubber gaskets, rubber floor tiles, rubber seals, conveyor belts, etc. |

| Glass Materials | tempered glass, frosted glass, flat glass, wired glass, insulating glass, laminated glass, hot bending glass, glass bricks, etc. |

| Other Materials | animal carcasses, RDF derivatives, biomass straw, garden waste, electronic waste, medical waste, used clothing, textile waste, etc. |

Ⅳ. Application of double shaft shredder in different industries

With its powerful performance, the double shaft shredder can process a variety of waste materials. Next, let’s learn about the fields in which the double shaft shredder can be used.

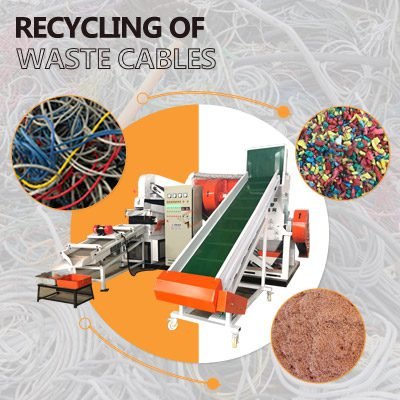

⭐ Scrap Wire And Cable Recycling

Playing a key role in scrap wire and cable recycling, the double shaft shredder can shred various wires and cables into small pieces through its rotating and shearing blades for subsequent processing and utilization. In the recycling process of scrap wires and cables, this equipment is usually used in conjunction with a copper wire granulator. It can not only achieves the reuse of resources, but also increases the recovery rate of copper and aluminum, creating economic value.

⭐ Plastic Recycling

The double shaft shredder can not only tear various plastic products such as plastic bottles, plastic bags, plastic tubes, etc. into uniform fragments, further reducing the volume and storage space of waste plastics, but also make it easier to sort and reprocess plastics during the recycling process. Furthermore, the double shaft shredder also has stable operating performance and can effectively meet the processing needs of a large number of plastic waste. This highly efficient processing method can not only reduce environmental pollution, but also reduce labor costs and production time, bringing considerable economic benefits to the enterprise.

⭐ Scrap Metal Recycling

Our double shaft shredder also can efficiently crush metals of various shapes and materials, including scrap car shells, scrap home appliances, scrap steel, scrap aluminum, etc. It is an important equipment for metal recycling and reuse. The use of double shaft shredders can solve the problem of waste metal disposal and reduce environmental pollution, and increase the stacking intensity of waste metal, making it easier to transport and recycle. In addition, by strictly controlling the feed size, the double shaft shredder can also handle the shredding of light and thin metals of a certain intensity without causing blockage, further improving the efficiency.

⭐ Wood Processing

The double shaft shredder is able to meet the different needs of wood processing and effectively improve the utilization rate and value of wood. In the field of wood product manufacturing, double shaft shredders can handle wood products waste(such as boards, wood strips, etc.) into pieces for easy recycling. In the field of scrap wood recycling, double shaft shredders can quickly process scrap wood (such as used furniture, wooden pallets, etc.) into reusable fragments, reducing the waste of wood resources and environmental pollution. In the field of forestry waste treatment, double shaft shredders can process decayed tree, branches and other forestry waste into small pieces for easy recycling or incineration.

THE APPLICATION of double shaft shredders is not limited to the above-mentioned fields, but also plays an important role in many industries such as glass products, rubber products, et paper making, etc. Its wide range of applications and efficient processing capabilities make it an ideal choice of modern industrial production.

Ⅴ. The operation and maintenance of double shaft shredder

Of course, no matter how good a machine is, it still needs maintenance to ensure good operating conditions, and the double shaft shredder is no exception. Here are some simple maintenance methods to help extend the service life of machine and improve work efficiency.

⭐ Preparation Before Operation

- Before operating a double shaft shredder, make sure you understand and follow the equipment’s safety regulations and operator’s manual.

- Make sure the work area is clean and tidy, and avoid debris that may interfere with operation.

- Wear appropriate personal protective equipment, such as gloves and goggles, to protect your own safety.

⭐ Correct Operation

- Put the raw materials evenly into the feed port of the double shaft shredder. Do not put in too much to avoid clogging the equipment.

- Before feeding raw materials, make sure the double shaft shredder has been started and is in normal working condition.

- During the shredding process, do not place your fingers, arms or other body parts close to the blades and rollers of the double shaft shredder to avoid accidental injury.

- Observe the working status and load conditions of the double shaft shredder. If any abnormality is found, stop the equipment immediately and perform repair.

⭐ Maintenance

- After shredding, turn off the double shaft shredder, disconnect the power supply, and clean the residue inside the device to ensure the normal operation of the device.

- Clean and lubricate the double shaft shredder regularly to maintain its normal working condition and life.

- Regularly check the blades, bearings and other easily worn parts of the double shaft shredder. If severe wear is found, replace them in time to avoid affecting the shredding effect and equipment performance.

Ⅵ. Conclusion

IN SUMMARY, as an efficient industrial equipment, the double shaft shredder can handle a wide variety of raw materials, as evidenced by its wide application in multiple industries. Through its efficient shredding capacity, wide range of applications, safe and reliable operation and easy maintenance, the double shaft shredder not only improves production efficiency, but also promotes the recycling of resources.