Beste Katalysator-Recyclingmaschine zum Verkauf BSGH-Granulator

BSGH Granulator spielt seit mehr als 10 Jahren eine wichtige Rolle bei der Recyclingproduktion von Katalysatoren. Wir bieten originelle Designs und qualitativ hochwertige Produkte und gewährleisten bei jeder von uns bereitgestellten Lösung Spitzenleistung und Zuverlässigkeit.

Um Edelmetalle zurückzugewinnen, muss zunächst das PGM-haltige Wabenmaterial aus dem Katalysator extrahiert werden. Die beste Lösung zur Extraktion dieses Materials ist die Verwendung einer hydraulischen Katalysator-Recyclingmaschine.

Schneidteil

+ Größe: 1100*800*2360

+ Gewicht: 324 kg

+ Leistung: 3KW

Staubsammlung

+ Größe: 940*530*2000

+ Gewicht: 40KG

+ Leistung: 2,2KW

Wie funktioniert ein Katalysator?

Die hydraulische Katalysator-Recyclingmaschine ist mit einem großen scharfen Messer ausgestattet, und seine dicke Klinge kann die Metallhülle des Katalysators leicht zerbrechen. Um die Maschine zu benutzen,

-

Erster Schritt

Sie müssen den Katalysator nur unter die Klinge der Maschine legen und der Katalysator wird durch die scharfe Klinge in zwei Hälften geteilt.

-

Zweiter Schritt

Nach der maschinellen Bearbeitung können Sie das mit PGMs beschichtete Wabenkeramikmaterial manuell abziehen.

Was kann eine Katalysator-Recyclingmaschine leisten?

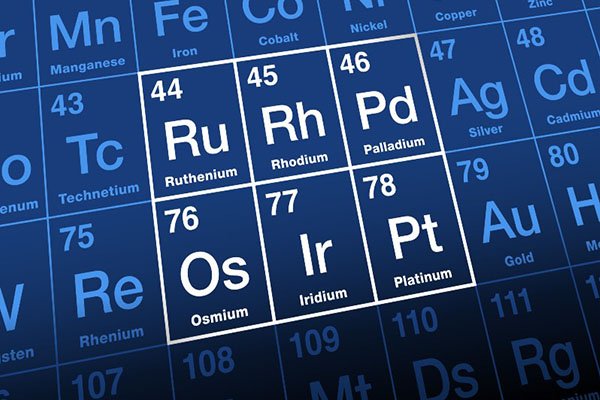

Der Dreiwegekatalysator ist das wichtigste Abgasreinigungsgerät im Abgassystem eines Autos. Er kann die drei wichtigsten Schadstoffe im Abgas in unschädliche Stoffe umwandeln. Der Katalysator enthält Edelmetalle wie Platin, Rhodium und Palladium. Die Seltenheit, Bedeutung und hohe physikalische und chemische Stabilität dieser Edelmetalle machen sie sehr teuer. Daher hat der Altkatalysator einen hohen Recyclingwert.

Die Katalysator-Recyclingmaschine von BSGH Granulator verwendet hauptsächlich physikalische Methoden, um die wabenförmigen Keramikmaterialien, die Edelmetalle wie Platin, Rhodium und Palladium enthalten, aus dem Katalysator zu extrahieren.

Hier sind einige Maschinendemonstrationen

Das im Dreiwegekatalysator enthaltene Platin, Rhodium und Palladium sind allesamt Platingruppenmetalle (PGMs). Diese Metalle zeichnen sich durch eine helle Farbe, starke chemische Stabilität, Säure- und Alkalikorrosionsbeständigkeit und hervorragende katalytische Leistung aus.

Laut einer Umfrage in den Vereinigten Staaten im Jahr 2021 betragen die weltweiten Reserven an PGMs nur 69.000 Tonnen, aber sie haben ein großes breites Anwendungsspektrum und spielen in vielen Bereichen eine wichtige Rolle, darunter Petrochemie, Umweltschutz, Medizin, Energiespeicherung, Wasserstoffenergie, neue Materialien und auch Automobile

Aufgrund des Mangels an PGMs müssen die entsprechenden Bergbauunternehmen weltweit Minen schließen und Expansionspläne aufgeben. Unter diesen Umständen ist das Recycling und die Wiederverwendung von PGMs besonders wichtig.

Man kann sagen, dass das Recycling von Katalysatoren nicht nur Ressourcenknappheit lindern, sondern auch zur Verringerung der Umweltverschmutzung und zur Erreichung einer nachhaltigen Entwicklung beitragen kann.

Das Recycling von Katalysatoren ist von großer Bedeutung und bringt hohe wirtschaftliche Gewinne. Wie hoch ist also der Gewinn, den man durch das Recycling von Katalysatoren erzielen kann? Wie sind die Entwicklungsaussichten?

Der größte Bedarf an PGMs besteht im Automobilbereich. Mit der Entwicklung der Automobilindustrie und der allmählichen Zunahme der Anzahl von Autos sind PGMs sehr knapp und nur noch in geringer Menge vorhanden, sodass Recycling und Wiederverwendung zur Hauptquelle für PGMs werden. Und die recycelten PGMs haben immer noch die gleichen Eigenschaften wie mineralische PGMs, sodass das Recycling von Katalysatoren Ihnen hohe wirtschaftliche Gewinne bringen kann.

Nach der Verarbeitung durch die Katalysator-Recyclingmaschine von BSGH Granulator erhalten Sie mit PGMs beschichtete Wabenkeramikmaterialien. Sie können das Material durch mehrere Prozesse wie Zerkleinern, Mahlen und Raffinieren weiter zu Edelmetallpulver verarbeiten. Sie können diese Wabenkeramikmaterialien auch direkt verkaufen und hohe Gewinne erzielen.

Aus einem Kilogramm Katalysator lassen sich etwa 0,2 bis 5 Gramm PGMs extrahieren, wobei die Extraktionsmenge hauptsächlich von der Qualität des Dreiwegekatalysators abhängt. Derzeit liegt der Preis für 1 Gramm Rhodium bei etwa 130 bis 250 US-Dollar, für 1 Gramm Palladium bei etwa 30 bis 50 US-Dollar und für 1 Gramm Platin bei etwa 25 bis 40 US-Dollar.

Auch in Zukunft werden Kraftstofffahrzeuge eine dominierende Stellung einnehmen und mit der kontinuierlichen Entwicklung der Wasserstoffenergieindustrie, des Platinschmucks, der Glasfaserindustrie und der elektronischen Informationsherstellungsindustrie wird die Nachfrage nach Platingruppenmetallen allmählich steigen.

Abschluss

Platingruppenmetalle sind knapp, können zu hohen Preisen verkauft werden und bieten in Zukunft viel Entwicklungsspielraum. Daher ist das Recycling von Katalysatoren ein Geschäft mit idealen Gewinnen.

Vorteile der BSGH-Granulator-Katalysator-Recyclingmaschine

BSGH Granulator kontrolliert die Qualität der Recyclingmaschinen für Katalysatoren streng. Wir verwenden die besten Materialien, die fortschrittlichste Technologie und die beste Konfiguration zur Herstellung der Maschinen und führen während des Produktionsprozesses ein ausgefeiltes Management durch. Daher weist jede von BSGH Granulator ausgelieferte Maschine eine hohe Haltbarkeit und die beste Leistung auf.

Die Klinge der Maschine besteht aus H13-Stahl, der der Klinge eine hohe Festigkeit, Härte, gute Zähigkeit, gute Verschleißfestigkeit und ausgezeichnete thermische Stabilität verleiht und sicherstellt, dass die Klinge auch unter hohem Druck und hohen Temperaturen ihre Stabilität behält.

Die Maschine ist mit einer Hydraulikausrüstung ausgestattet, die leistungsstärker ist und Ihre Rohstoffe schnell verarbeiten kann. Die Verarbeitung eines Katalysators dauert nur etwa 25 Sekunden, was Ihre Produktionseffizienz verbessern kann.

Die Maschine ist kompakt aufgebaut und platzsparend.

Die Maschine ist mit einem Staubsammelsystem ausgestattet, das den während des Produktionsprozesses entstehenden Staub effektiv und ohne Umweltverschmutzung auffangen und die Gesundheit der Bediener schützen kann.

Haben Sie Fragen zur Maschine? Mehr anzeigen FAQs.

Warum uns wählen

Ihr führender professioneller Recyclinghersteller

BSGH Granulator ist ein Unternehmen, das sich auf die Herstellung aller Arten von Altmetallrecyclingmaschinen spezialisiert hat. Wir bieten vor allem qualitativ hochwertige und kostengünstige Wir bieten nicht nur Maschinen zum Recycling von Katalysatoren, sondern auch Abisoliermaschinen, Maschinen zum Zerkleinern von Kupferdrähten, Motorrecyclingmaschinen und Kühlerrecyclingmaschinen an. Von der Maschinenkonstruktion über Forschung und Entwicklung und Fertigung bis hin zu Vertrieb und Service wird jeder Teil von unserem professionellen Personal betreut. Unsere umfangreiche Produktlinie deckt ein breites Anwendungsspektrum ab, sodass Sie bei BSGH Granulator Komplettlösungen erhalten.

25 Jahre reichhaltige Erfahrung

BSGH Granulator hat eine langjährige Erfahrung in der Altmetallrecyclingbranche von mehr als 25 Jahren. Unser Fachwissen kann alle Ihre Fragen zu Altmetallrecyclingmaschinen beantworten und unser professionelles Team kann Ihnen konstruktive Vorschläge für Ihr Recyclinggeschäft unterbreiten. Wenn Sie sich für uns entscheiden, entscheiden Sie sich für einen zuverlässigen Partner mit umfassender Erfahrung.

Ein globaler Vertriebsauftritt

Unsere Maschinen sind nicht nur in China beliebt, sondern werden auch weltweit verkauft. Im Laufe der Jahre haben wir für beide Seiten vorteilhafte Partnerschaften mit Kunden in mehr als 80 Ländern und Regionen aufgebaut, und unsere Maschinen wurden von den meisten Kunden gut angenommen.

Strenge Qualitätskontrolle

Wir kontrollieren jeden Teil des Maschinenproduktionsprozesses streng. Wir haben höchste Qualitätsstandards und Kontrollpläne entwickelt. Wir wählen die hochwertigsten Materialien zur Herstellung der Maschinen aus und führen während des Produktionsprozesses Stichprobenprüfungen und umfassende Tests an den Maschinen durch, um sicherzustellen, dass sie 99% von Maschinen desselben Typs auf dem Markt übertreffen.

Bestehen auf Integrität

Bei der Zusammenarbeit mit unseren Kunden legen wir Wert auf Integrität. Wir halten auf jeden Fall, was wir versprechen, und Sie können sich bei Ihrer Entscheidung, mit BSGH Granulator zusammenzuarbeiten, sicher fühlen.

Unsere Ifat-Messe und Kanton-Messe

Teilen Sie uns Ihren Bedarf an Recyclingmaschinen für Katalysatoren mit

Teilen Sie uns gerne Ihren individuellen Bedarf an einer Katalysator-Recyclingmaschine mit. Wir entwickeln einzigartige Verarbeitungslösungen, die Ihnen dabei helfen, effizienter und effektiver zu recyceln.

Am häufigsten gestellte Fragen

Dazu muss lediglich der Katalysator aus dem Altfahrzeug ausgebaut und das Auspuffrohr demontiert werden.

Ja. Solange Ihr Katalysator Platin, Palladium und Rhodium enthält, hat er einen hohen Recyclingwert.

Ja. Unsere Maschine verfügt über eine neue Struktur, die den Bediener vom Sägeblatt fernhält.

Die Maschine ist außerdem mit einem Staubsammelsystem ausgestattet, das keinen schädlichen Staub erzeugt. So kann die Sicherheit des Bedieners wirksam geschützt werden.

- Whatsapp/Viber: 008613772508206

- E-Mail:coppergranulator@bsghrecycling.com

- Website: https://bsghgranulator.com/

andere Verwandte Produkte

Wir bieten auch Maschinen zum Recycling verschiedener Autoteile an, um Ihren unterschiedlichen Anforderungen gerecht zu werden. Wenn Sie interessiert sind, können Sie gerne auf den untenstehenden Link klicken, um mehr über unsere Produkte zu erfahren, oder Sie können uns direkt kontaktieren.

Metallzerkleinerer

MS-D800 Vertical Double Shaft Shredder

Metallzerkleinerer

MS-D1800 Heavy-duty industrial shredder

Metallzerkleinerer

MS-D1300 IBC Container Shredder

Scrap Motor Recycling