Best Catalytic Converter Recycling Machine For Sale BSGH Granulator

BSGH Granulator play an important role in catalytic converter recycling production for more than 10 years, we offer original designs and high-quality products, ensuring top performance and reliability in every solution we provide.

To recover precious metals, first need to extract the honeycomb material containing PGMs in the catalytic converter. Using a hydraulic catalytic converter recycling machine is the best solution for extracting this material.

Cutting Part

+ Size: 1100*800*2360

+ Weight: 324KG

+ Power: 3KW

Dust Collection

+ Size: 940*530*2000

+ Weight: 40KG

+ Power: 2.2KW

How Does catalytic converter Work?

The hydraulic catalytic converter recycling machine is equipped with a large sharp knife, and its thick blade can easily break the metal shell of the catalytic converter. To use the machine,

-

First Step

you only need to place the catalytic converter under the machine's blade, and the catalytic converter will be split in half by the sharp blade.

-

Second Step

After the machine processing, you can manually peel off the honeycomb ceramic material coated with PGMs.

What can catalytic converter Recycling Machine do?

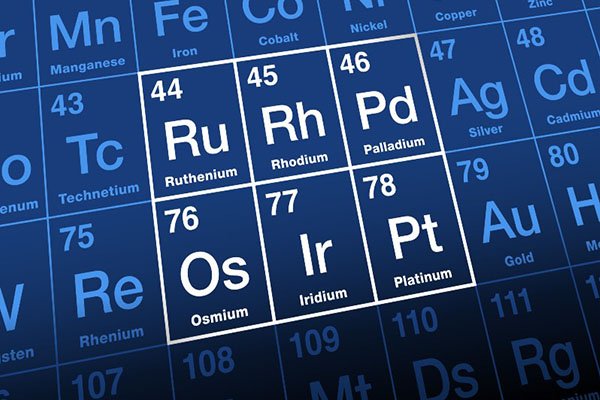

The three-way catalytic converter is the most important exhaust gas purification device installed in the automobile exhaust system. It can convert the three main harmful substances in the exhaust gas into harmless substances. The catalytic converter contains precious metals such as platinum, rhodium, and palladium. The scarcity, importance, and high physical and chemical stability of these precious metals make them very expensive. Therefore, the waste catalytic converter has a high recycling value.

BSGH Granulator’s catalytic converter recycling machine mainly uses physical methods to extract the honeycomb ceramic materials containing precious metals such as platinum, rhodium and palladium from the catalytic converter.

Here are some machine demonstrations

The platinum, rhodium and palladium contained in the three-way catalytic converter are all platinum group metals (PGMs). These metals have the characteristics of bright color, strong chemical stability, acid and alkali corrosion resistance and excellent catalytic performance.

According to a survey in the United States in 2021, the global reserves of PGMs are only 69,000 tons, but they have a great wide application range, playing an important role in many fields, including Including petrochemicals, environmental protection, medicine, energy storage, hydrogen energy, new materials, and also automobiles

Due to the shortage of PGMs, relevant mining companies around the world have to close mines and cancel expansion plans. Under this situation, the recycling and reuse of PGMs is particularly important.

It can be said that recycling catalytic converters can not only alleviate resource shortages, but also help reduce environmental pollution and achieve sustainable development.

Recycling catalytic converters has important significance and high economic profits. So, how much profit can be obtained from recycling catalytic converters? What is its development prospect?

Automobiles are the largest demand area for PGMs. With the development of the automobile industry and the gradual increase in the number of cars, PGMs are very scarce and in short supply, so recycling and reuse will become the main source of PGMs. And the recycled PGMs still have the same properties as mineral PGMs, so recycling catalytic converters can bring you high economic profits.

After being processed by BSGH Granulator's catalytic converter recycling machine, you will get honeycomb ceramic materials coated with PGMs. You can further process the material into precious metal powder through multiple processes such as crushing, grinding, and refining. You can also sell these honeycomb ceramic materials directly and get rich profits.

You can extract about 0.2 to 5 grams of PGMs from one kilogram of catalytic converter, and the amount of extraction depends mainly on the quality of the three-way catalytic converter. Currently, the price of 1 gram of rhodium is about 130 to 250 US dollars, 1 gram of palladium is about 30 to 50 US dollars, and 1 gram of platinum is about 25 to 40 US dollars.

In the future, fuel vehicles will still occupy a dominant position, and with the continuous development of the hydrogen energy industry, platinum jewelry, glass fiber industry and electronic information manufacturing industry, the demand for platinum group metals will gradually increase.

Conclusion

Platinum group metals are in short supply, can be sold at high prices, and have broad development space in the future. Therefore, recycling catalytic converters is a business with ideal profits.

Advantages Of BSGH Granulator Catalytic Converter Recycling Machine

BSGH Granulator strictly controls the quality of catalytic converter recycling machines. We use the best materials, the most advanced technology and the best configuration to manufacture machines, and carry out refined management during the production process. Therefore, each machine shipped from BSGH Granulator maintains high durability and the best performance.

The blade of the machine is made of H13 steel, which keeps the blade high strength, high hardness, good toughness, good wear resistance, and excellent thermal stability, ensuring that the blade can still maintain stability under high pressure and high temperature environment.

The machine is equipped with hydraulic equipment, which is more powerful and can process your raw materials quickly. It takes about only 25 seconds to process a catalytic converter, which can improve your production efficiency.

The machine has a compact structure and saves space.

The machine is equipped with a dust collection system, which can effectively collect the dust generated during the production process, with no pollution, and ensure the health of the operators.

Have any questions about the machine? See more FAQs.

Why Choose Us

Your Leading Professional Recycling Manufacturer

BSGH Granulator is a company that specializes in producing all kinds of scrap metal recycling machines. We mainly provide high-quality and low-cost not only offer catalytic converter recycling machine but also wire stripping machines, copper wire crushing machines, motor recycling machines and radiator recycling machines. From machine design, research and development, manufacturing, to sales and service, every part is handled by our professional staff. Our extensive product line covers a diverse range of applications, so you can get one-stop solutions at BSGH Granulator.

25 years of rich experience

BSGH Granulator has a rich history in the scrap metal recycling industry for more than 25 years. Our expertise can answer all your questions about scrap metal recycling machines, and our professional team can provide constructive suggestions for your recycling business. Choosing us means choosing a reliable partner with rich experience.

A global sales footprint

Our machines are not only popular in China, but also sold all over the world. Over the years, we have established mutually beneficial partnerships with customers in more than 80 countries and regions, and our machines have been well received by most customers.

Strict Quality Control

We strictly control every part of the machine production process. We have developed the highest quality standards and control plans. We choose the best quality materials to manufacture the machines, and conduct sampling inspections and comprehensive tests on the machines during the production process to ensure that they exceed 99% of the same type of machines on the market.

Insistence on integrity

In the process of cooperation with our customers, we adhere to the spirit of integrity. We will definitely do what we promise, and you can feel confident in your decision to cooperate with BSGH Granulator.

Our Ifat Fair And Canton Fair

Tell Us About Your Catalytic Converter Recycling Machine Needs

Please feel free to tell us your customization need from a catalytic converter recycling machine. We’ll come up with unique processing solutions that will help you recycle more efficiently and effectively.

Most Frequently Asked Questions

You only need to remove the catalytic converter from the scrapped vehicle and dismantle the exhaust pipe.

Yes. As long as your catalytic converter contains platinum, palladium, and rhodium, it has a high recycling value.

Yes. Our machine adopts a new structure to keep the operator away from the blade.

The machine is also equipped with a dust collection system, which will not produce harmful dust. So it can effectively protect the safety of the operator.

- Whatsapp/Viber: 008613772508206

- Email:coppergranulator@bsghrecycling.com

- Website: https://bsghgranulator.com/

other Related Products

We also provide machines for recycling various parts of cars to meet your different needs. If you are interested, you are welcome to click the link below to learn more about our products, or you can contact us directly.

Wire Stripper Machine

BS-30A BX Wire Stripping Machine

Hydraulic Alligator Shear

AS-4000 Scrap Metal Alligator Shears

Metal Shredder Machine

MS-D1600 Scrap Iron Shredder

Metal Shredder Machine