transformer dismantling machine

- Extracts copper windings from small transformers, keeping windings intact to maximize their recycling value.

- User-friendly design, simple automated process (cutting + winding pulling), perfect for daily small transformer recycling.

- Built with industrial-grade components, our transformer dismantling machine is designed for high safety and reliable daily operation.

What is transformer dismantling machine?

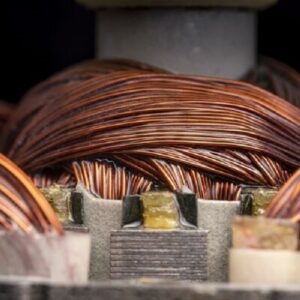

A transformer dismantling machine is specialized recycling equipment designed to separate and recover valuable materials—especially copper windings and silicon steel sheets from waste transformers. Instead of manually cutting or burning, the machine quickly and cleanly pulls the copper wires out of the transformer core, ensuring a higher copper recovery rate, better purity, and improved efficiency.

Stop losing profit — discover how our technology can transform your recovery operation today.

transformer dismantling machine Details

Der BSGH Small Transformer Dismantling Machine is the ultimate solution for efficiently recycling copper from transformers under 100mm. In just seconds, this machine cleanly separates copper windings from the silicon steel core, delivering a higher copper recovery rate and superior metal purity. Unlike traditional manual dismantling, this advanced copper recovery equipment not only saves time but also maximizes the profit you can earn from every transformer. For scrap metal recyclers, this means faster operations, reduced labor costs, and more valuable output.

| Artikel | Parameter |

|---|---|

| Maschinengewicht | 240 kg |

| Größe | L1200*W730*H1230MM |

| Package Size | L1260*W830*H1350MM |

| Motorleistung | 4KW |

| Package Weight | 300KG |

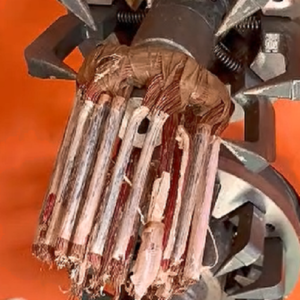

Witness Precision in Action: How to disposal Transformers

In this test video, you can see that transformer disposal is become easier with our machine. We will see the transformer dismantling procedure step by step:

- First, the small scrap transformer is securely fixed.

- Next, high-strength blades cleanly cut the transformer into half.

- Last, the pulling claws smoothly extracting the entire copper winding assembly in one continuous motion—quickly, cleanly, and without damage.

The result? A perfectly intact copper coil ready for resale, and an iron core that remains whole, enabling maximum material recovery. This seamless operation ensures high efficiency and outstanding value recovery from every unit processed.

advantages of transformer dismantling machine

Durable use

The heat-treated cutting blade and wear-resistant pulling four-claw require no frequent replacement.

support customized

For transformer dismantling, we support customization according to different sizes of your materials.

Hands-free control

The foot pedal allows the operator to keep hands free to control the blades and claws while precise cutting and pulling.

small footprint

The compact design allows for flexible, space-saving placement in various small recycling stations and scrapyards.

versatile application

It is fully compatible with all common types of small transformers, including E-shaped, Japanese-shaped, F-shaped, and C-shaped.

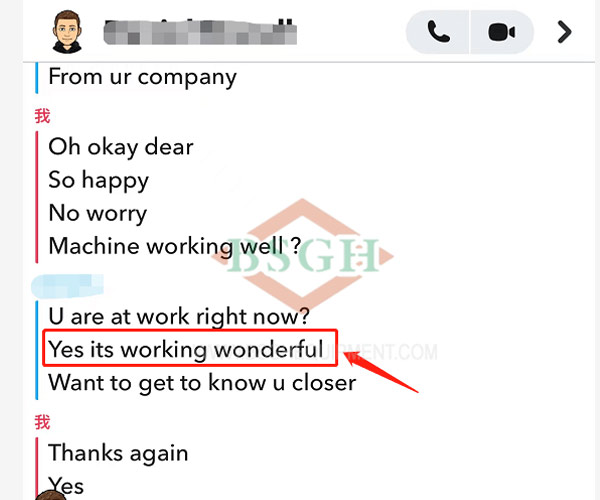

customer case for transformer dismantling machine

A customer from Germany ran a small recycling station.

Challenges:

- Limited space. His recycling station is only about 30 square meters, making it impossible to invest in large machinery.

2. They previously dismantled small transformers manually, which was not only inefficient but also resulted in copper wires frequently breaking. The recovery rate was only around 85%, resulting in significant profit losses.

Solution: We recommended our transformer dismantling machine to him. His compact design and specialized capabilities for handling small transformers immediately captured his attention. After further research, he quickly invested in our machine.

Result:

1. Easily fits in the corner of his station, saving space.

2. Efficiency increased nearly 10x—one operator now processes a transformer in only 20s.

3. Hydraulic pulling removes windings completely intact, boosting copper recovery from 85% to over 99.9%.

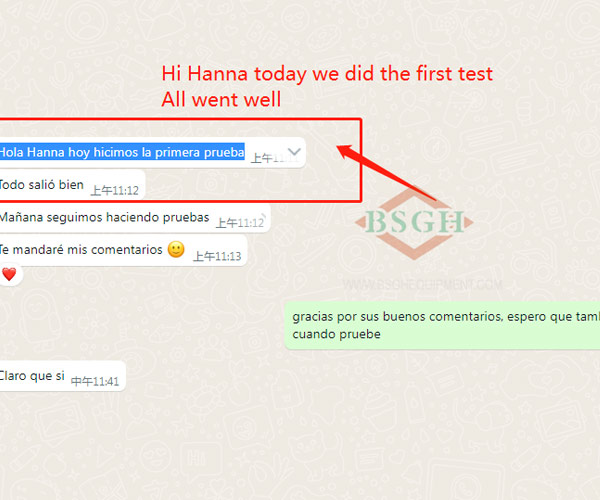

Customer feedback:

“I was amazed at this machine, no bigger than a washing machine, that fits perfectly in my station. I can run it alone with a foot pedal, finishing one in 20 seconds, besides, its copper recovery rate is 99.99%, resulting in saving labor costs and increasing profits. Very satisfied!”

best transformer dismantling machine supplier in China

For nearly 30 years, BSGH Granulator has been committed to delivering the best transformer dismantling machines to global customers. Our equipment is designed to perform reliably in real-world recycling conditions, helping scrap metal recyclers maximize copper recovery, efficiency, and overall profitability.

- With 60,000+ square meters of factory and automated production lines, we are proud to know how to meet your real needs.

Our product line goes far beyond transformer dismantling machines. BSGH-Granulator manufactures a complete range of recycling equipment, including wire strippers, copper cable granulators, radiator recycling machines, metal shredders, balers, and briquette presses. Every machine is produced under strict quality control standards to ensure reliable performance and long service life.

We provide a complete order process—from quotation and contract signing to production, testing, delivery, and installation. With BSGH, you gain not only high-quality recycling machines but also a trusted long-term partner dedicated to your success.

Join recyclers worldwide who trust BSGH Granulator for durable, efficient, and customized transformer dismantling solutions. Contact us today for a free consultation and custom quote.

transformer dismantling machine Working video

See our transformer dismantling machine in action in the video below. To see more detailed photos, specifications, or even a live demonstration, please do not hesitate to contact us. We’re happy to provide you with all the information you need.

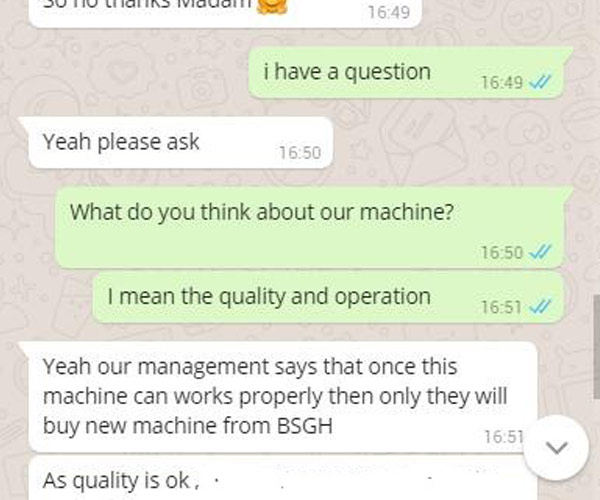

What Our Clients Say

The best proof of performance comes directly from our customers. Below, you’ll find real reviews from recyclers who have put our transformer dismantling machine to the test.

Zertifizierung

Every metal recycling machine manufactured by BSGH Granulator has applied CE-Zertifizierung.