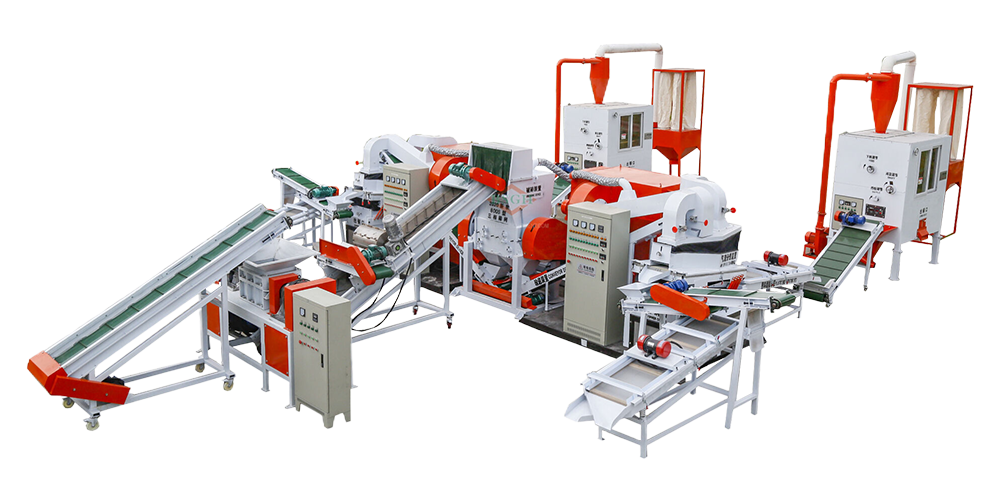

Un cliente de Canadá compró un granulador de cable de alta eficiencia ECO1000

Noticias Contáctenos Correo electrónico: coppergranulator@bsghrecycling.com WeChat/Whatsapp/Viber: +86 13772508206 Sitio web: www.bsghgranulator.com Coopere con BSGH Granulator, una decisión beneficiosa para todos ¡Buenas noticias! El 28 de junio de 2024, BSGH Granulator