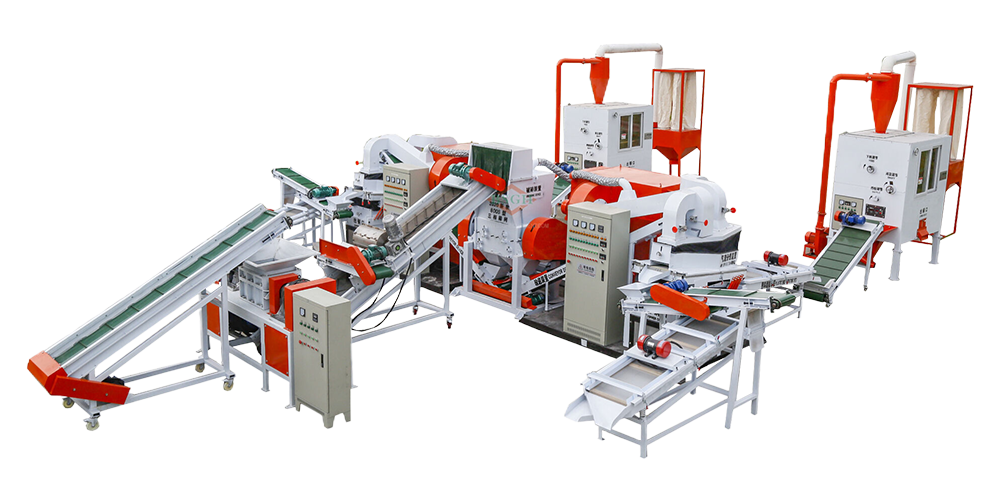

4 Sets Of BS-1200P Radiator Stripper Recycling Machines Delivered To Romania

At 11 a.m. on July 15, 2024, Beijing time, we sent four sets of BS-1200P radiator recycling machines to a Romanian customer who purchased his

Customize your BSGH Granulator copper plastic separator with unique features. Optimize performance by tailoring the equipment to your unique needs. BSGH Granulator is a versatile solution that allows you to tailor settings, configurations, and functionality to your specific requirements. Increase productivity and precision by customizing the separator to your specific processing needs. Experience increased control and productivity with a copper plastic separator custom-made for your company. Trust BSGH Granulator to provide a customized solution that is in sync with your operating goals.

Explore the cost-effective efficiency of the copper plastic separator from BSGH Granulator, a dependable solution developed to optimize your resource recovery process. Our advanced technique ensures perfect separation of copper and plastic materials, reducing waste and increasing profits.

This separator, designed for longevity and performance, provides a cost-effective solution without sacrificing quality. Profit from lower operational costs while maintaining high material purity criteria.

The commitment of BSGH Granulator to affordability extends beyond the original investment, since our separators are designed for energy efficiency, which contributes to long-term cost savings.

Our low-cost copper plastic separator has simple controls that will streamline your operation and reduce downtime. BSGH Granulator, with a focus on simplicity and utility, provides a solution that matches your budgetary limits without sacrificing effectiveness.

Count on our experience to improve your recycling capacities, delivering a dependable and cost-effective solution for your copper-plastic separation requirements. Our copper plastic separator is the sensible choice for organizations seeking both cost-effectiveness and performance in their recycling processes since BSGH Granulator is committed to delivering value without compromise.

As it comes to your copper plastic separator, BSGH Granulator prioritizes quality. We diligently focus on guaranteeing the durability, precision, and dependability of all of our equipment. BSGH Granulator products are distinguished by their outstanding craftsmanship and attention to detail. Elevate your recycling processes with a copper plastic separator that satisfies the highest criteria, delivering long-lasting performance and consistent results. Experience the difference that quality-driven engineering can make for efficient and successful copper-plastic separation.

For raw material: cutting and drilling Processing raw materials involves the procedures of cutting and drilling.

Following the initial processing of raw materials, the subsequent stage involves subjecting them to heat treatment.

This stage primarily involves welding spare parts.

This stage consists of producing the main shaft, air separator system shaft, rollers, eccentric shaft, and other machine components. Precision at this stage is crucial for machine performance. Machine functionality and efficiency depend on the accurate machining of these vital components.

This stage primarily involves the welding of the pre-processed components into the semi-finished assembly of the main crusher, air separator, and dust removal device.

Assemble all completed spare parts through welding to create semi-finished products.

When dealing with semi-finished products, we undergo a debugging and testing phase to fine-tune the machine’s performance post-disassembly, ensuring it operates at its optimal level.

After breakdown, we polished and painted carefully. After assembly and troubleshooting, a new copper granulator machine was ready to use.

Leading China Wire Granulators

Can Compete with Euro Granulators

BSGH Granulator takes pride in our commitment to cutting-edge technology and exceptional craftsmanship as a leading copper plastic separator producer.

We lead the industry in producing high-performance solutions for efficient material separation, with a focus on innovation and client satisfaction. Our cutting-edge manufacturing facilities and trained team ensure that each copper plastic separator is of the highest quality and durability.

We prioritize customer needs by providing a variety of adjustable options that allow us to design our separators to specific needs. Our commitment to quality extends beyond product creation also offer full support, from installation to continuing technical assistance.

You can rely on us for a dependable and cost-effective solution that fits the requirements of current recycling processes. BSGH Granulator is your reliable partner, continuously supplying high-quality copper plastic separators that redefine efficiency and dependability in the recycling business.

As a manufacturer specializing in copper plastic separators, we have extensive technical knowledge to ensure that each separator is designed for maximum efficiency and longevity.

We follow to strict quality requirements throughout the manufacturing process of our copper plastic separators. Every unit is rigorously tested and meets industry standards to ensure its dependability and durability, even in the most demanding working settings.

We are committed to providing cutting-edge solutions and are always incorporating revolutionary technologies into our goods. We retain our dedication to cutting-edge recycling technology by ensuring that our copper plastic separating machines are efficient and user-friendly.

Our commitment to clients extends beyond the acquisition of copper plastic separators. We provide extensive technical support, maintenance services, and critical components to help our clients optimize the performance of their copper plastic separator machines.

To purchase your copper plastic separator from us, please visit our website or contact our sales staff directly. We are here to help you with smooth and effective procurement.

Starting by sharing your specifications with us. Our experts will assess your individual requirements and advise you on the best copper plastic separator to meet your goals.

Our team can customize the copper plastic separator to match your unique requirements. Once we have finalized the data and criteria, we will provide you with a detailed price for the tailored solution.

Once your order is confirmed and payment procedures are completed, we commence the construction of your copper plastic separator. Each unit is meticulously crafted to adhere to our stringent standards for quality and performance.

Your copper plastic separator will be shipped safely after production is completed. We provide installation services, operating training, and continuous maintenance help to ensure optimal functionality after purchase.

Specify your wire granulator machine needs. We styling solutions to your processing needs to maximize recycling performance and efficiency.

At 11 a.m. on July 15, 2024, Beijing time, we sent four sets of BS-1200P radiator recycling machines to a Romanian customer who purchased his

In early March, an Iraq customer visited our One-Stop Recycling Solution website. He discovered that our company offers a comprehensive range of metal recycling machines,

News Contact us Email: coppergranulator@bsghrecycling.com WeChat/Whatsapp/Viber: +86 13772508206 Website: www.bsghgranulator.com Mr.Schmidt, From Germany, Satisfied With Our Machines On June 30, 2024, we received the deposit

Best Copper Wire Granulator Manufacturer in China. We provide one-stop recycling solutions for copper wire, motors, radiators, and other scrap metals — including shredders, crushers, and separation systems. With customers across the globe, we are committed to delivering reliable, high-performance recycling solutions that meet your needs.

© All rights reserved by BSGH Granulator.

WhatsApp us

Please fill in the following form(tell us your requests or you can choose from):

| D Series Different Capacity |

| 50KG/H, 70KG/H, 100KG/H, 200KG/H, 300KG/H |

| N Series Different Capacity |

| 300~500KG/H, 400~600KG/H, 1T/H, 1200~1500KG/H |

According above different capacities, tell us your requests, once we get your detailed information for your requests, we will contact you at the first time with professional solutions and support from buying to using.

Please fill in the following form(tell us your requests or you can choose from):

| Home use wire stripper machine |

| 1.5MM-38MM; 2-45MM; 2-76MM; 2-60MM; |

| Industrial cable stripping machine |

| 10-120MM; 10-160MM; 60-200MM |

According to your requests, I’ll recommend the suitable machine.

We have all kinds of radiator recycling machines, besides single radiator stripper machines and radiator recycling lines, radiator cutting machines.

Our machines are capable of processing all kinds of scrap radiators, including car radiators, water tank radiators and AC radiators, aluminum-clad radiators etc.

Our metal baler can processing all types of scrap metals, besides light metal and heavy metals; ferrous metal and non-ferrous metals;

our machine have from small pressure to big pressure 80T, 125T, 135T, 160T, 200T, 250T,315T and 400T, if you not know which pressure should you choose, so please send us your material picture below and ask for a free quote now!

We have:

Can you tell me which kinds of material you want to process? click below and send material picture.

Process Motor Shell | Motor Stator | Motor Shaft

Motor Shell Cutting | Motor Stator Recycling

Auto Starter Cutting | Auto Starter Pressing | Car Starter Heating | Car Starter Pulling Machine

Car Alternator Cutting Machine | Car Alternator Pulling Machine

Motor Stator Recycling Line | Motor Rotor Recycling Line | Whole Motor Recycling Plant

For Small Transformer Recycling

Compressor Shell Cutting Machine | Compressor Stator Recycling

Mainly for Recycling Ceiling Fan Motors

For All Kinds of Car Magnetic Switch

For All Kinds of Electric Bike Hub Motors

Mainly for Press All Kinds of Motor Parts | Support Customized