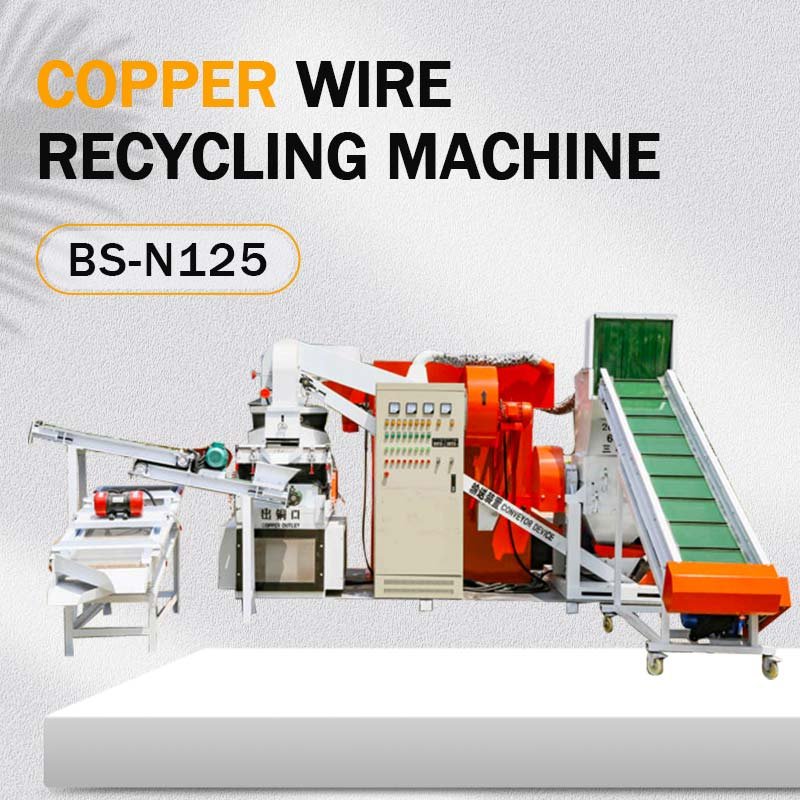

The copper recycling machine is called the scrap wire and cable recycling machine. It can crush scrap copper wires and separate copper and plastic through a series of processing and operations of the machine.

The copper recycling machine improves the efficiency of scrap cable processing, ensures the purity and quality of copper granules, reduces production costs, and complies with environmental protection and sustainable development.

SO, WHAT SHOULD YOU PAY ATTENTION TO WHEN OPERATING THE COPPER RECYCLING MACHINE?

The Following Is The Answer.

Ⅰ. Preparation Before Operation

Before you use the copper recycling machine, you’d better do some inspection on the machine.

⭐ Equipment Inspection

First of all, you should inspect whether the equipment is in good condition, including Système électrique et Mechanical Parts:

+ Electric System Inspection

Power and Wire Inspection

- Make sure the power cord is not damaged, wire connections are secure, and there are no exposed wires to avoid short circuits or electric shock risks.

Control Device Inspection

- Check that all control switches, relays and other electrical control devices are working properly and are not damaged or malfunctioning.

Grounding Check

- Make sure the equipment is properly grounded to prevent electrical shock accidents.

Protection Device Inspection

- Make sure that safety devices such as overload protection, emergency stop button are effective and can automatically cut off the power supply when necessary to ensure equipment safety.

+ Mechanical Parts Inspection

- CHECK all moving parts of the machine to prevent objects from falling into the moving parts during operation.

- CHECK whether the motor is running normally, without abnormal sound or vibration, and ensure that the motor direction is consistent with the equipment requirements.

- CHECK whether the bolts of the main components are loose during transportation.

- CHECK whether the bearings in each part need to be lubricated.

⭐Safety Precautions

Next, you should do some safety precautions before start on the copper recycling machine.

+ Wear Appropriate Protective Equipment

Wear Protective Equipment

- Before operating the copper recycling machine, you should wear protective equipment as required, including work clothes, work hats, protective glasses or masks, etc., to prevent flying chips or debris generated during the operation of the machine from causing harm to the operator.

Avoid Using Damaged or Expired Protective Gear

- Make sure any protective gear you use is intact and not past its expiration date.

Use Safety Shoes

- Wear non-slip, wear-resistant safety shoes for added protection and stability of your feet.

Tie Up Your Cuffs

- In order to prevent your work clothes from being caught in the machine, you should tie up your cuffs during operation to avoid potential safety risks.

+ Ensure A Safe Working Environment

Ventilation Environment

- The copper recycling machine should be placed in a well-ventilated environment to maintain a good working environment and avoid the accumulation of heat and exhaust gas generated by the operation of the machine.

Equipment Placement

- The copper recycling machine should be placed in a clean, pollution-free environment to ensure the hygiene and safety of the working area. In addition, the copper recycling machine needs to be placed on flat ground, which can reduce the impact of vibration on the equipment and maintain stable operation of the equipment.

⭐ Operator Training

At last, you should organize special training for operators. The operators must be familiar with the operation process and master safe operating procedures.

Operation Training

- Train the operators to fully understand the equipment performance, precautions and maintenance knowledge, and ensure that the operator can operate the copper recycling machine correctly and safely.

Technical Training

- Provide technical training for operators, including equipment performance, precautions and maintenance knowledge, to ensure that operators can master the operation and maintenance of the equipment.

Safety Operation Specifications

- Emphasize that operators must stand on the side of the copper recycling machine to prevent flying objects from hitting people. After work every day, the machine should be left idling for 5-10 minutes to ensure that the material in the crusher is completely removed before shutting down.

Prohibition of Private Disassembly

- It is emphasized that operators are not allowed to disassemble the copper recycling machine without permission, and maintenance tools are not allowed to be placed in the machine.

Ⅱ. Precautions for Operating Copper Recycling Machine

When you are ready to operate the copper recycling machine, you should pay attention to the flowing points:

⭐ Pre-start-up Check

You need to ensure that the copper recycling machine is in the best condition before putting it into use, to improve production efficiency and product quality.

+ Confirm Device Status

Before starting the machine each time, the entire production line of the copper recycling machine should be allowed to idle for 5 to 10 Minutes to check whether the equipment is operating normally. Only when there is no abnormality can the material be put into production.

+ Check the Quality of Raw Materials

When preparing scrap wires and cables, you need to pay attention to their specifications, types, materials, etc., ensuring that the copper wires meet the processing requirements of the copper recycling machine to avoid affecting the normal operation of the equipment due to raw material problems. Also you need to note there’s should haven’t iron materials to avoid damage to the blades of copper recycling machine.

⭐ Precautions During Operation

In the working process of copper recycling machine, you should notice the following aspects:

+ Follow the Operating Procedures

The operator should use the copper recycling machine strictly according to the instructions. According to the startup steps of the copper recycling machine, start the machine main body and control system, set the processing parameters according to production requirements, and adjust the position and angle of the blades.

+ Pay Attention to the Speed and Quantity of Raw Materials

During the production process, it is best to classify and crush the raw materials first, especially to separate the copper wire and the aluminum wire separately for recycling. In addition, when using the copper recycling machine, we need to maintain a uniform and reasonable feeding speed to avoid excessive feeding and material accumulation, which will cause blockage inside the copper recycling machine and make the sorting effect unsatisfactory.

+ Abnormal Situation Handling

During operation, if any equipment failure is found, it should be stopped immediately and handled correspondingly according to the type of failure.

Blockage Problem

- If the copper recycling machine does not discharge or discharges less material, it may be caused by poor adjustment of the airflow separator, inadequate vibration frequency, loose sealing, etc. The solution includes checking and adjusting the seal of the airflow separator, cleaning the blocked material, and restarting the machine to discharge the material.

Low Separation Rate

- Check whether the copper recycling machine is level, and ensure the separation effect of the vibrating table.

- Check the copper recycling machine sieve mesh, and choose the appropriate mesh aperture to avoid metal and plastic granules being sieved out together.

Machine Failure

- Check whether the screws of the copper recycling machine are loose, whether the bearings need to be lubricated, whether the belt is loose, etc. If you encounter a circuit failure such as tripping, you should first check the circuit part.

Ⅲ. Maintenance of Copper Recycling Machine

The maintenance of the copper recycling machine is very important, which can ensure the efficient and stable operation of the equipment and extend its service life.

⭐ Clean the Equipment

When using the copper recycling machine, there are two parts that are more prone to blockage, and these two parts are also where we need to clean frequently

✓ Feeding Port

Feeding is the main premise of copper recycling machine processing. Because of this, the feed port will be blocked when in use. If the material specifications carried in the feed port are too large, there will be serious congestion, resulting in a decrease in the feeding speed. Therefore, daily cleaning of the feed port is the basic condition to ensure the normal and efficient operation of the machine.

✓ Sieve Mesh

The sieve mesh is the main guarantee for making the copper and plastic granules processed by the copper recycling machine purer and of higher quality. It is also because of this that the sieve mesh will be extremely seriously blocked after long-term use and work. Therefore, when using the copper recycling machine, you must clean them regularly to clear the blockage of the sieve mesh, which is beneficial to the processing effect of the copper rice machine.

⭐ Check and Replace the Wearing Parts

After the copper recycling machine has been used for a period of time, it should be inspected, especially the blades, bearings, gears and other vulnerable parts should be inspected or replaced in time if they are worn or damaged to extend the service life of the machine.

At the same time, the connecting bolts and nuts should be carefully checked for looseness to ensure that there is sufficient lubrication grease.

⭐Regular Inspection of Equipment

You also should attach importance to regular inspection of the machine.

✓ Inspection and Maintenance of Lubrication System

Regularly check whether the lubricating oil in the bearings and eccentrics has dried up. If it is lacking, add lubricating oil. And check whether the fixing bolts are loose.

Add new grease to each operating part every 40 Hours of operation, and add new grease to the crusher bearing every 8 hours of operation to ensure the smooth operation of the machine.

✓ Inspection and Maintenance of the Blade

The blade will become blunt after a period of production, which will affect the crushing and sorting effects. When grinding the blade, mechanical grinder should be selected. After repeated grinding, the blade will become narrower. Once the gap between the movable blade and fixed blade cannot meet the crushing requirements, the old blade should be replaced. As grinding or replacing the blade, turn off the power before operation. The gap between movable blade and fixed blade should be adjusted every time after grinding or replacing the blade.

✓ Equipment Cleaning and Dust Removal

After shutdown, the dust particles inside the machine should be cleaned to maintain air circulation. The dust collection should be cleaned regularly to remove the dust on the bags and maintain air permeability. Regularly and thoroughly clean and dust the motor, bearings and other parts to keep the equipment clean and avoid dust accumulation that affects machine performance.

Ⅳ. Conclusion

As an efficient copper resource recovery equipment, the operation and maintenance of copper recycling machine is very important. Through strict pre-operation preparation, standardized operation process, timely abnormal situation handling and regular equipment maintenance, the safe and efficient operation of the copper recycling machine can be ensured, and your production efficiency can be improved.