I. Introduction

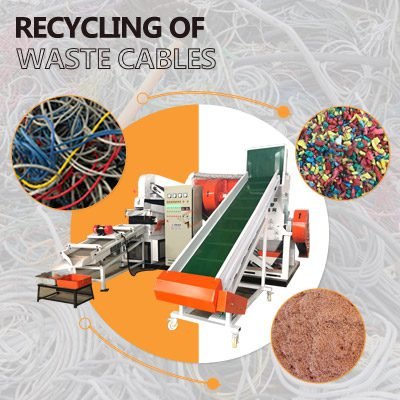

Overview of Cable Granulation Systems

Cable granulation systems represent a cornerstone in contemporary recycling methodologies, improve the efficient processing of cables and wires. These systems, equipped with crushers, granulators and separators, intricately dissect cables, expediting the extraction of valuable materials. Notably, the recovery of metals such as copper and aluminum is optimized. The benefits extend to energy efficiency, where cable granulation systems display a notable reduction in energy consumption compared to traditional methods. Moreover, the streamlined process contributes to cost-effectiveness by diminishing manual labor requirements. As recycling technology advances, cable granulation systems strengthen their position as critical tools for improving the efficacy and economics of recycling procedures.

II. Efficiency of Operations

Speed up the process of handling wires

Enhancing the efficiency of wire handling processes is very important, and this imperative is met through integrating innovative solutions such as cable granulation systems etc. These systems represent a technological leap, streamlining and expediting wire handling procedures. By automating traditionally manual tasks, cable granulation systems eliminate bottlenecks, significantly accelerating the pace of operations. This acceleration not only optimizes time utilization but also minimizes idle periods, leading to a more dynamic workflow. The result is a substantial reduction in processing time, translating into heightened overall efficiency. Cable granulation systems, under their ability to expedite wire handling, play a pivotal role in optimizing industrial processes and maximizing productivity.

Less work being done by hand

Transitioning away from manual labor, the integration of automation in wire processing signifies a departure from traditional labor-intensive methods. Cable granulation systems now assume the intricacies once managed by human hands, streamlining processes, and reducing dependence on manual work. This shift not only expedites operations but also fosters a safer work environment by alleviating physical strain and associated risks. This transformative change reflects the ongoing technological evolution in industrial practices, prioritizing efficiency, and precision. With decreasing manual involvement, attention shifts towards optimizing the capabilities of automated systems, pointing towards a future where the nuances of wire processing are seamlessly managed through advanced technologies.

Better overall throughput

Integrating advanced cable granulation technologies into wire processing recycling business will make your output bigger in equal time. These modern technologies are crucial in enhancing the efficiency and speed of the recycling process, so it’s different from the traditional method. Cable granulation systems have a more accurate structure to improve operations by automating and speeding up the extraction of valuable elements from cables. This optimized throughput is especially beneficial for recycling plants with large operational capacity, as these systems can handle a large number of cables in a specific time, Its influence on the efficiency of wire processing activities is significant and transformative.

III. Maximized Copper Recovery

Getting More Copper

Cable granulation systems are meticulously crafted with the primary goal of maximizing copper recovery a valuable and extensively utilized equipment. Employing sophisticated processing methods, these systems are designed to ensure the efficient extraction of copper from cables. One-time feeding, completed by multi-machine collaboration, high efficiency and low manpower can be achieved by one copper wire granulator machine. By leveraging advanced technologies, cable granulation systems play a pivotal role in the extraction and recycling of copper, an endeavor that aligns with the economic and sustainable utilization of this precious and versatile metal.

Higher levels of purity

The granulation method plays a pivotal role in enhancing the purity of recovered copper, a critical factor in industries requiring high-quality copper for production processes. The precision of granulation ensures that impurities are minimized so that you can get more purer copper. This heightened purity is of paramount importance, elevating the value of the recovered copper in the market. Industries reliant on top-tier copper for manufacturing benefit significantly from this method, as the increased purity not only aligns with their stringent quality requirements but also enhances the market value of the recovered copper.

Benefits for the economy

Efficient copper recovery not only benefits the environment but also proves advantageous for the economy. The utilization of granulation systems in obtaining recycled copper stands as a cost-effective alternative. In comparison to purchasing raw copper, recycled copper obtained through these systems often comes at a more economical price point. This affordability renders it a favorable option for recyclers, contributing to the circular economy by reducing the demand for new raw materials while simultaneously presenting a financially prudent choice in the economic landscape.

IV. Cost-effectiveness

Lower operational costs

Cable granulation systems play an important role in lowering operating costs by automating jobs, reducing dependency on labor-intensive procedures, and maximizing resource use. This streamlined technique not only reduces the need for heavy physical work, but it also considerably improves the cost-effectiveness of cleaning processes in a variety of industrial applications.

Lower requirement for raw resources

Effective copper recycling reduces the need for costly and harmful extraction procedures while also conserving resources. Reusing copper from outdated cables makes the operation financially viable and reduces the environmental impact of mining raw copper minerals using conventional ways.

Long-Term Profits

Over time, wire granulation systems can prove to be a financially beneficial investment. These solutions provide greater performance over time in addition to cost savings through increased efficiency. For example, if you choose a BSGH Granulator copper granulator machine with reputable and durable, it will work ten years at least which means it can earn money for you constantly for quite a long time. In this way, recyclers can create a long-term business plan that guarantees profitability and success in the evolving recycling market by putting such methods into practice.

More cable granulation systems for your choose:

| Especificação | Capacidade | Modelo |

| Big Cable Granulation System | 800~2000KG/H | BS-F3000 | BS-F1000 | BS-A1100 | ECO1000 |

| Middle Cable Granulator | 300~700KG/H | BS-N130 | BS-D600 | BS-N125 | BS-D60 |

| Small Cable Granulator | 70~300KG/H | BS-D30 | BS-D20 | BS-D10 | BS-D75 |

| Single phase Cable Granulator | 20~60KG/H | BS-S10 |

V. Versatility and Adaptability

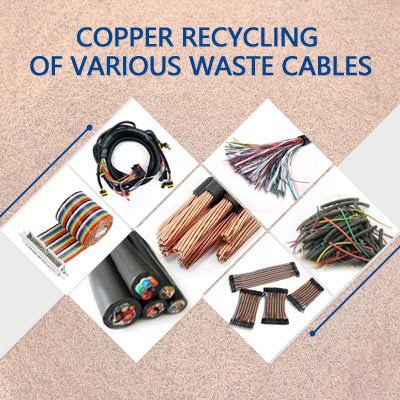

Handling Various Cable Types and Sizes

Cable grinding systems showcase remarkable flexibility, adeptly managing various cable types and sizes. This adaptability empowers recyclers to effectively handle a diverse range of materials, aligning with the dynamic demands of the recycling industry. The systems’ versatile design ensures responsiveness to evolving needs, enhancing their utility in the ever-changing landscape of recycling.

Compatible with a range of recycling operations

Designed for versatility, wire granulation systems seamlessly integrate with diverse recycling operations, offering easy adaptability to different sets and methods. Their capability to interface with various systems renders them invaluable for recyclers with a broad spectrum of needs, providing a flexible and efficient solution across a range of recycling scenarios.

Adapting to Industry Evolution

The adaptability of cable granulation systems proves invaluable in the ever-evolving recycling industry. Their inherent flexibility allows for seamless updates and modifications to align with emerging technologies and evolving industry standards. This dynamic feature ensures the continued relevance and utility of these systems in the face of industry advancements.

VI Technology and Service

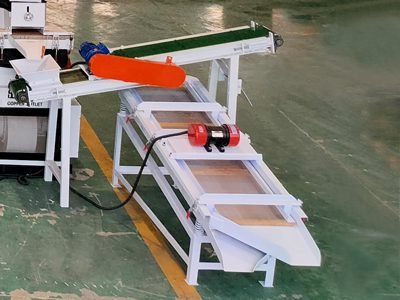

Separador de ar

We continue to innovate technology, improve service levels, and strive to provide customers with satisfactory services. The air separator’s effectiveness is fine-tuned through strategic control over wind force and angle. Compared with previous high-pressure separation methods on the market, it avoids the disadvantages of traditional methods and makes the recycling effect more accurate.

Mesa vibratória

Similarly, our vibrating table achieves optimal performance with precise adjustments to angle and frequency. It combined with air separator can make the recycled copper reaching at a very high purity.

Separador eletrostático

The inclusion of an electrostatic separator adds a layer of sophistication to our technological repertoire. Compared with air separator, it can process waste wires as thin as a hair in diameter, also able to handle more messy scrap wires as well. If you have wires like these, we advise you install electrostatic separator to you recycling line.

Serviço pós-venda

Beyond technology, our services are tailored to provide customized solutions, accommodating different types of wires and various recycling capacity needs. For your reference, every parts of the machine are rigorously designed, showcasing our commitment to achieving precision and efficiency in every aspect of our technological advancements and client-specific offerings.

Conclusão

In summary, a comprehensive review of the significant benefits associated with cable granulation devices underscores their pivotal role in modern recycling practices. These devices stand out for their capacity to enhance the efficiency of operations, facilitate increased copper recovery, offer cost-effectiveness, and exhibit versatile applications. Their adoption signifies a crucial step towards advancing resource recovery, cost efficiency, and environmental sustainability within the recycling landscape. By promoting the widespread integration of wire granulation systems, the recycling industry can harness their advantages to optimize cable handling, thereby bolstering the overall efficiency of operations and contributing to a more sustainable and eco-friendly approach to recycling practices.