Descrição do vídeo

Our hydraulic shears are popular in South America, Japan, the United Kingdom, Australia, etc. due to their good cutting effect, fast shearing speed, and long service life. The following is a test video we shot for an Australian customer.

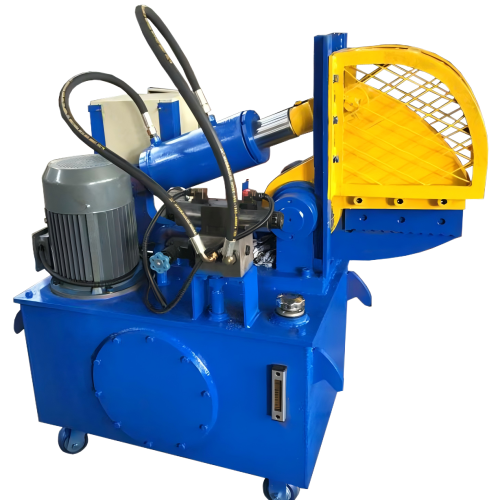

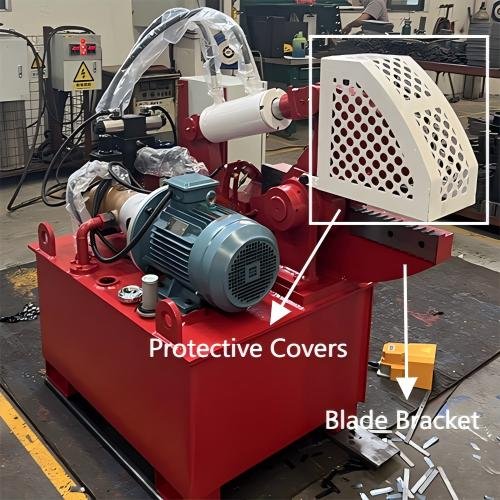

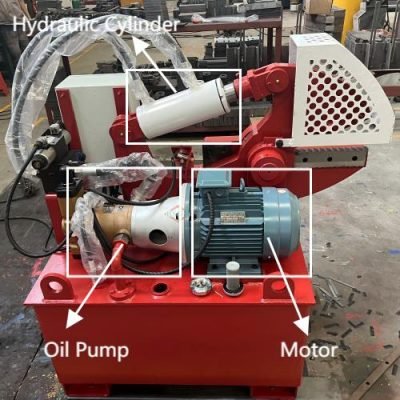

- Machine model: AS-250 hydraulic shear

- Customer from: Australia

- Capacidade Máxima de Cisalhamento: 250KN

- Max Blade Opening: 160mm

- Shearing times of per minute: 10-15

In 2022, an Australian customer who purchased a copper wire granulator from us contacted us again, seeking a cutting machine to process scrap cables before feeding them into the granulator. He also had some small round steel and iron plates that needed to be cut, so we recommended the AS-250 hydraulic shear to him. This machine is affordable, energy-saving, and requires low maintenance, it can help recyclers minimize costs and is an ideal solution for cutting various small metal materials. After the machine was produced, we sent a trial video to him, he was very satisfied and paid the balance quickly.