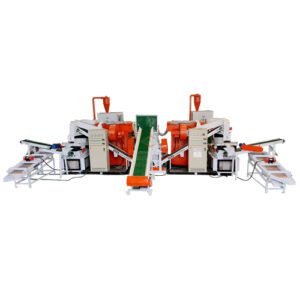

Britador de eixo vertical

– The vertical structure design realizes material crushing through the impact and collision between the high-speed rotating rotor and the fixed liner.

– It has a large crushing ratio and is especially suitable for fine crushing of medium and high-hardness materials.

– It is widely used in recycling, metallurgy, building materials, chemical industries, etc.

– High return on investment, bringing you significant economic benefits.

What is vertical shaft crusher?

Stop struggling with inefficient crushing! The BSGH Granulator vertical shaft crusher transforms waste into value—faster, cleaner, and with less hassle. One machine, limitless potential. Ready to upgrade your operation? Contact us now and take your recycling to the next level!

Vertical shaft crusher selection

We provide a full range of vertical shaft crusher models to provider you the most effective and well-suited solution for your needs, for any details you can send us an enquiry.

#1000 vertical shaft crusher

Motor: 22/30KW

Feeding Inlet: 1000*800MM

Outlet: 0-200MM

Wall Thickness: 35MM

Dimention: 2400*1800*3500MM

#1600 vertical shaft crusher

Motor: 90/132KW

Feeding Inlet: 1550*1400MM

Outlet: 0-300MM

Wall Thickness: 70MM

Dimention: 3200*2600*5000MM

#1800 vertical shaft crusher

Motor: 132KW

Feeding Inlet: 1550*1500MM

Outlet: 0-350MM

Wall Thickness: Φ220*20MM

Dimention: 3200*3000*4000MM

#2000 vertical shaft crusher

Motor: 160/220KW

Feeding Inlet: 1800*1500

Outlet: 0-400MM

Wall Thickness: 70MM

Dimention: 3700*3100*5000mm

Application of vertical shaft crusher

BSGH Granulator vertical shaft crusher is suitable for a wide range of waste materials, including household appliances such as refrigerators, washing machines, microwave ovens, electronic waste, scrap aluminum can bales, automobile parts such as engine blocks and exhaust pipes, and metals such as copper, iron, and aluminum, this machine is a multifunction one which can help you process many different types of waste material within one machine.

How does vertical shaft crusher work?

Vertical shaft crusher mainly reduces the size of materials by collision between the blades and material with the hard surface of the crushing chamber and collision between materials. It is mainly divided into the following four steps:

1. The material enters the machine from the feed port and falls into the rotating rotor.

2. The rotor spins at high speed, accelerating the materials outward with strong centrifugal force.

3. The raw materials collide with the hard wall of the crushing chamber, or the raw materials collide with each other, reducing the volume in continuous high-intensity impact, collision, and friction.

4. The material that finally meets the particle size requirements is discharged from the outlet at the bottom of the machine.

Advantage:

High Flexibility

Fácil operação

Time Saving

High Efficient

Pollution Free

Multifuncional

Durável

Long Life Time

High Quality Final product

Saving Money

Why choose BSGH Granulator vertical shaft crusher?

Compared with other types of crushers, VSI crusher has the following advantages, making it the first choice for fine crushing of high-hardness materials.

1. Unlike other crushers, BSGH Granulator vertical shaft crusher does not have any cutting tools, but instead uses the force of mutual impact to complete the material crushing process. This eliminates the need to replace wearing parts such as blades and hammers, reducing downtime and repair costs.

2. The crushing process of the VSI crusher can reduce flaky or elongated particles and produce high-quality final products with good shape, uniformity, and smooth surface.

3. Vertical crusher has excellent effects on materials of various hardness, especially when processing high-hardness household appliances, metals, rocks, and other materials.

4. This crusher focuses on the disintegration of input materials while avoiding damaging individual components, so it can quickly disintegrate valuable waste materials without causing individual components to emit harmful substances.

5. High flexibility. The output particle size of the vertical shredder can be changed by adjusting the rotor speed, feed amount, etc., without changing the screen or adjusting the blade gap.

Por que BSGH Granulator?

BSGH Granulator is one of the leading metal recycling machine manufacturers, holding over 70% of the market share in China.

As a crucial part of the recycling process, the performance of shredders directly impacts the quality of the final product. We offer a wide range of shredders, including eixo único e double-shaft shredders, hammer mill shredders, etc. Each is designed with different processing capacities and applications to meet diverse recycling needs.

The vertical crusher is a versatile, high-efficiency machine built for long-term performance. Constructed with high-strength manganese steel and precision bearings, it delivers durability and reliability. Its intelligent design reduces energy consumption and maintenance costs, making it ideal for recycling, construction, and mining applications.

We take quality seriously at every step—from material selection to final assembly—ensuring each vertical shredder meets the highest standards. Built for durability, safety, and top performance, our machines are engineered to handle the toughest industrial recycling demands with efficiency and reliability..

Before shipping, each machine is fully tested and trial-run, and we provide a testing video for you. You can trust in our dedication to quality and reliability.

Escolha Nossa Máquina sua escolha aconselhável

Advantages of vertical shaft crusher

Excelente efeito de trituração

Long life

Fácil instalação

Estável e durável

Fácil operação

Entre em contato conosco imediatamente para obter uma cotação razoável

Looking for a powerful and reliable vertical shaft shredder? Contact us now for a competitive quote! Engineered for efficiency and durability, our shredders deliver superior performance for industrial recycling. Let’s discuss the best solution for your needs now!