Des capacités de traitement puissantes vous aident à obtenir rapidement des avantages

Broyeur de câbles industriel pour le recyclage des câbles en cuivre et en aluminium

Introducing the forklift feeding BS-A1300 cable shredder for commercial use from BSGH Granulator – a heavy-duty machine engineered for efficient recycling of scrap wires and cables, provide you broken-free, built to last, reducing operation costs, the best equipment for various scrap yards, cable recycling factories, scrap metal recycling centers, etc.

Fabricant de déchiqueteur de câbles BS-A1300

Destructeur de câbles BS-A1300 is a patented product designed by BSGH Granulator, especially used for recycling large quantities of scrap copper and aluminum wires, better with a diameter below 30mm. The processing capacity can reach 2000-3000KG/H, efficiency is in a leading position in the world and it is a unique big machine.

Cette machine prend en charge l'alimentation continue par chariot élévateur, éliminant ainsi le besoin d'alimentation uniforme tout en maintenant d'excellents résultats de recyclage, sans risque de blocage dû à un excès de matériau. Cela permet un recyclage automatisé et mécanisé des câbles usagés, réduisant considérablement le besoin d'opération manuelle. Avec seulement 1 à 2 opérateurs, la machine peut fonctionner de manière fluide et efficace.

Galerie de machines

Si vous souhaitez une machine avec une capacité de traitement plus petite, nous vous recommandons fortement de choisir notre déchiqueteur de fils BS-A1100.

Machine de déchiquetage de fil BS-A1100 économique

BS-A1100 is a also heavy-duty industrial wire shredder machine that can also be fed by a forklift, saving time and effort. Its processing capacity is about 1200-1500KG/H. Although smaller than BS-A1300, they both have the same sturdy structure and long service life. In addition to various waste cables, BS-A1100 wire shredder has strong power and can process waste motor copper windings. Due to its special design, it has become a favorite of many large recycling plants in Europe and South America.

Galerie de machines

Choisissez-nous votre meilleur choix

industrial Cable Shredder To Maximize Your Recycling Efficiency

Taux de récupération des ressources élevé

Cable shredder can achieve high-precision copper-plastic separation while greatly improving production efficiency. Through at least two separation steps, 99.99% of copper resources in waste cables can be extracted from scrap cables. At the same time, we also have auxiliary equipment to help process special cables, ensuring that copper resources can be recovered to the maximum extent from almost all types of cables.

Des résultats économiques remarquables

Our industrial cable shredder machines process cables and wires into smooth, bright copper granules with no oxidation or impurities such as plastic particles, achieving 100% purity. Also with higher processing capacity, these ensures you can get higher economic returns for you.

Construction robuste

Compared to common copper cable shredders, BS-A1300 and BS-A1100 feature a more robust structure and a thicker, sturdier body. Ordinary copper cable shredders may become jammed if they are fed too much material at once, whereas our heavy-duty models are designed with an exceptional load-bearing capacity. Not only do they support forklift feeding without the risk of jamming, but they are also more durable and resistant to damage, ensuring long-lasting performance.

Faibles besoins d'entretien

Lors de la conception de nos machines, nous avons accordé la priorité à la rentabilité des recycleurs, garantissant de faibles besoins opérationnels et de maintenance. Notre broyeur de câbles consomme environ 20% d'énergie de moins que des machines de taille similaire, minimisant ainsi la consommation d'énergie. Construit avec des composants de haute qualité, il est durable avec une usure minimale, réduisant le besoin de réparations et de remplacements fréquents et minimisant les temps d'arrêt. À long terme, les économies sur les coûts d'exploitation dépassent de loin le prix initial de la machine, ce qui en fait un investissement brillant et rentable.

Protection de l'environnement et zéro pollution

Notre machine est conçue pour favoriser la récupération et la réutilisation des ressources en cuivre, réduisant ainsi le besoin de nouvelles mines de cuivre, tout en garantissant qu'elle ne pollue pas l'environnement. Elle est équipée d'un système avancé de dépoussiérage par impulsions qui collecte efficacement toute la poussière générée pendant le processus de recyclage, créant ainsi un environnement de travail propre et sain. L'entretien du système de dépoussiérage est simple : il suffit de nettoyer régulièrement le sac à poussière pour qu'il fonctionne correctement.

devis gratuit

Si vous devez traiter un grand nombre de câbles et disposez d'une source stable de câbles usagés, et si vous recherchez une solution de recyclage abordable, hautement efficace et facile à utiliser, nos broyeurs de cuivre BS-A1300 et BS-A1100 sont le meilleur choix. Contactez-nous et nous serons heureux de vous aider.

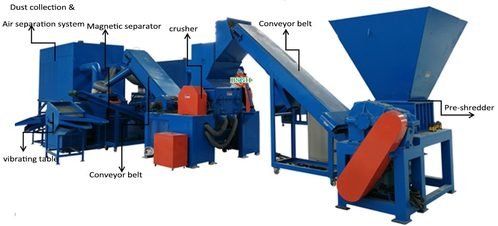

structure of industrial copper cable shredder machine

Notre destructeur de câbles comprend principalement les pièces suivantes : pré-broyeur, concasseur principal, bandes transporteuses, séparateur d'air, table vibrante, séparateur magnétique, dispositif de dépoussiérage et armoire électrique. Leurs fonctions et étapes de travail sont à droite

Les fonctions de chaque partie sont les suivantes :

La première étape du destructeur de câbles est le processus de pré-déchiquetage. Il peut déchiqueter les câbles usagés en 6 à 15 cm pour faciliter l'étape suivante. Cet appareil utile réduit efficacement la charge de travail du broyeur principal pour augmenter la capacité de traitement globale du destructeur de fils de cuivre, réduire le meulage des lames et rendre la machine plus durable. Le pré-déchiqueteur du BS-A1300 est notre conception spéciale, qui est unique au monde.

L'étape la plus importante du système de recyclage des câbles. Il peut transformer les câbles usagés en un mélange de granulés métalliques et de granulés plastiques de 3 à 5 mm. Notre concasseur principal est doté de 48 lames mobiles et de 6 lames fixes, et est entraîné par un moteur de 110 kW, ce qui le rend très puissant.

Le convoyeur à bande relie toutes les parties de la machine. Il peut transporter les matières premières vers différentes parties de la machine, réduisant ainsi le besoin d'opérations manuelles.

La première étape du système de séparation, également la technologie la plus avancée de l'industrie, utilise la différence de poids entre le métal et le plastique pour extraire des métaux tels que le cuivre et l'aluminium.

La deuxième étape du système de séparation, il utilise la différence de fréquence de vibration des deux matériaux pour trier, puis vous pouvez obtenir 99,99% de granules de cuivre à partir du mélange. Seul le broyeur de câbles chinois est équipé de petites tables vibrantes, tandis que notre petite table vibrante est la plus précise et la plus durable d'entre elles.

Le séparateur magnétique est un équipement auxiliaire essentiel pour le traitement des câbles contenant du fer. Il sépare le fer de tous les mélanges pour garantir que le produit final est du cuivre pur ou de l'aluminium 100%.

Le dispositif de collecte de poussière collectera en continu toute la poussière issue du processus de recyclage, permettant à notre destructeur de câbles de répondre aux normes environnementales de tous les pays.

Le système de contrôle électronique est utilisé pour contrôler la liaison, l'action unique, l'alarme de surcharge, etc. de chaque composant du destructeur de câbles, ainsi que pour diagnostiquer leur fonctionnement.

Pré-broyeur hydraulique - la conception unique au monde

The pre-shredder used in BS-A1300 industrial cable shredder is specially designed by BSGH Granulator. It has the characteristics of high efficiency, high torque, reliability, etc. It is the best partner to help you carry out large-scale cable recycling operations.

- Conception à arbre unique : avec des lames carrées pour accrocher le matériau, de sorte qu'il peut être alimenté en continu par chariot élévateur, ce qui minimise le risque de blocage dû à une surcharge dans la chambre de concassage.

- Il peut pré-déchiqueter les câbles usagés en bandes de 6 à 15 cm de long, plus petites que les bandes de 5 à 25 cm produites par le broyeur à double arbre, ce qui facilite le traitement du concasseur principal.

- Pour résoudre le problème selon lequel le broyeur à arbre unique ne peut pas accrocher le fil lors du traitement de câbles relativement durs, nous avons conçu un système de poussée auxiliaire hydraulique pour empêcher la machine de tourner au ralenti.

- We have upgraded the hydraulic pushing system. The ordinary pushing system adopts the horizontal pushing method. When there is not enough material in the crushing chamber, there may be empty crushing. However, our hydraulic pushing equipment adopts pushing from up to down, ensuring that the waste cable can be pushed to the blades every time the pusher is extended, and the hydraulic rod has a fast pull-back speed, which effectively reduces the gap time and improves the crushing efficiency.

Granulateur BSGH - Votre partenaire fiable en Chine

Avec plus de 25 ans d'expérience, nous sommes le plus ancien manufacturer of industrial cable shredder machines since 1995 in China.

Nos machines sont exportées vers 80+ pays et régions du monde.

Nous avons établi des relations de coopération amicales et mutuellement bénéfiques avec plus de 100 000 clients.

Notre part de marché en Chine a atteint 70%~80%.

Quels services pouvez-vous obtenir auprès de BSGH Granulator

Un service professionnel de solution unique vous aide à gérer les problèmes de recyclage

Granulateur BSGH est une marque de confiance dans l'industrie du recyclage du cuivre depuis près de 30 ans, avec une vaste expertise dans la fabrication et la vente de broyeurs de câbles. Notre équipe technique dédiée s'engage à développer et à perfectionner la technologie de recyclage des câbles pour répondre à diverses exigences de production, en aidant les clients à récupérer efficacement des matériaux précieux et à maximiser leurs profits.

Machines de haute qualité

Nous sommes une marque de machines de recyclage de cuivre haut de gamme avec une part de marché de plus de 80% en Chine. Nous ne fournissons que des broyeurs de câbles de très haute qualité, ils disposent d'une technologie de recyclage précise et de systèmes d'exploitation stables pour créer en permanence de la valeur pour vous. Ils combinent parfaitement des prix raisonnables et une excellente qualité pour vous fournir les solutions de recyclage les plus précieuses, réalisant une situation gagnant-gagnant de faible coût et de rendement élevé.

Service de personnalisation flexible

Chez BSGH Granulator, notre équipe d'experts en R&D excelle dans la création de solutions personnalisées adaptées à vos besoins spécifiques. Envoyez-nous simplement des photos de vos matières premières ainsi que vos exigences particulières, et nous concevrons une solution flexible pour répondre exactement à vos exigences. Qu'il s'agisse du matériau de la lame, du matériau et de la taille de l'écran, de la tension ou de la couleur de la machine, nous proposons des options entièrement personnalisables pour garantir votre satisfaction.

Équipe de service professionnelle

Avant la vente, nous vous proposons les suggestions de sélection de modèles les plus adaptées, des services de personnalisation et vous aidons à terminer le processus de commande afin que vous puissiez vivre une expérience d'achat fluide. Pendant la vente, nous vous aidons à concevoir gratuitement des plans de placement de machines et fournissons des méthodes d'installation et de débogage des machines ainsi que la formation des travailleurs. Après la vente, nous offrons une garantie de 12 mois et un service de réponse rapide en ligne à vie.

Bon retour

As the industry’s leading brands, our customers are all over the world. Our main overseas markets are concentrated in the United States, South America, Europe, Thailand, etc., and the customer repurchase rate has reached 60%. There is no doubt that our cable shredder has also been widely praised by overseas customers. The following is the feedback from some customers.

Non seulement l'entreprise fait du bon travail, mais elle le fait aussi avec de bonnes personnes. Chaque fois que nous nous renseignons sur les machines, ils demandent toujours nos exigences, recommandent des installations et font preuve de professionnalisme dans l'examen de nos besoins.

Warning: Undefined variable $ekit_testimonial_client_image_size in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 68

Warning: Trying to access array offset on value of type null in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 68

Warning: Undefined variable $ekit_testimonial_client_image_size in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 69

Warning: Trying to access array offset on value of type null in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 69

Nous utilisons les machines de marque BSGH Granulator depuis 8 ans et à chaque fois, j'ai de nouvelles exigences, nous pouvons toujours envoyer un message à Hannah pour un service rapide et efficace. Nous avons été bien entretenus dans des machines professionnelles, telles que le hachoir à fil de cuivre et l'éplucheur de radiateur, nous sommes très heureux de nous attaquer bientôt au marché du recyclage en Amérique.

Warning: Undefined variable $ekit_testimonial_client_image_size in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 68

Warning: Trying to access array offset on value of type null in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 68

Warning: Undefined variable $ekit_testimonial_client_image_size in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 69

Warning: Trying to access array offset on value of type null in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 69

Lorsque les équipements sont programmés et confirmés, les conversations téléphoniques et les appels vidéo en face à face sont toujours amicaux et courtois. La société BSGH Granulator est sans aucun doute une entreprise cinq étoiles ! », Je suis fier de travailler avec la société BSGH !

Warning: Undefined variable $ekit_testimonial_client_image_size in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 68

Warning: Trying to access array offset on value of type null in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 68

Warning: Undefined variable $ekit_testimonial_client_image_size in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 69

Warning: Trying to access array offset on value of type null in /home/u427840971/domains/bsghgranulator.com/public_html/wp-content/plugins/elementskit-lite/widgets/testimonial/style/style5.php on line 69

FAQ

Oui, une lubrification régulière de la machine contribuera à maintenir ses performances élevées et à prolonger sa durée de vie.

Nos machines peuvent fournir des performances stables pendant plus de dix ans dans le cadre d'une utilisation normale et d'un entretien régulier, ce qui en fait votre meilleur choix.

Oui, vous pouvez être rassuré. Toutes les machines du granulateur BSGH sont certifiées CE.

Non, la différence de poids entre le cuivre et l'aluminium est si faible que le broyeur de câbles ne peut pas les séparer proprement. Lorsque vous devez traiter à la fois des fils de cuivre et d'aluminium, placez-les séparément dans la machine.

Notre déchiqueteur de câbles industriel peut traiter des câbles en aluminium, des câbles en cuivre, des fils en caoutchouc, des fils souples, des câbles blindés, des fils de métier à tisser de voiture, etc.

Lorsque les lames deviennent émoussées, vous pouvez les retirer et les affûter avant de continuer à les utiliser. Lorsque l'effet de broyage devient faible, veuillez réduire manuellement la distance entre les lames mobiles et les lames fixes. Lorsque la distance a été réglée à 0 mais que l'effet de broyage idéal ne peut toujours pas être obtenu, vous devez remplacer les lames.

Parlons-nous de vos besoins en matière de broyeur de câbles usagés

Veuillez nous indiquer ce dont vous avez besoin en matière de destructeurs de câbles. Nous travaillerons pour trouver des options qui répondront à vos besoins.

- Whatsapp/Viber : 008613772508206

- Courriel : coppergranulator@bsghrecycling.com

- Site Web : https://bsghgranulator.com/

industrial Cable Shredder video

Produit connexe

Si vous êtes une petite usine de recyclage ou une casse de taille moyenne, nous avons également de nombreux petits destructeurs de câbles et destructeurs de câbles de taille moyenne pour votre choix.

-

Granulateurs de câbles en cuivre industriels de grande capacité à vendre BS-F3000

Lire la suite -

Granulateur de fil de cuivre BS-F1000 d'une capacité de 1 T/H en provenance de Chine

Lire la suite -

Machine de déchiquetage de câbles BS-N130 à vendre à chaud de 400 à 700 kg/h

Lire la suite -

Machine de recyclage de fils de cuivre BS-N125 pour câbles de rebut

Lire la suite -

Meilleur prix BS-D65 Séparateur électrostatique Granulateur de fil de cuivre à vendre

Lire la suite -

Machine de séparation de fil de cuivre BS-D60 au meilleur rapport qualité-prix en vente

Lire la suite -

Rectifieuse de fil BS-D30 avec 300 kg/h

Lire la suite -

Broyeur de fils de cuivre BS-D85 abordable avec séparateur électrostatique à vendre

Lire la suite