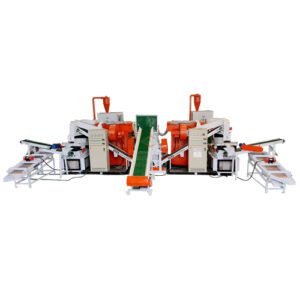

Granulateur BSGH En tant que premier fabricant chinois à concevoir, fabriquer et commercialiser des broyeurs à cuivre, nous proposons les meilleures solutions de recyclage de câbles usagés. Depuis de nombreuses années, nos machines à câbles en cuivre sont présentes dans le monde entier et nos produits sont unanimement salués par la plupart des clients du monde entier.