Fabricant d'électroaimants de levage

L'électroaimant de levage est un dispositif spécialisé qui exploite les propriétés électriques et magnétiques pour soulever les matériaux auxquels il est attaché. Il est essentiel pour soulever et transporter des matériaux ferromagnétiques dans diverses industries comme la métallurgie, l'exploitation minière, la machinerie, la construction navale et le transport. De plus, il sert à des fins telles que la manipulation électromagnétique, le centrage de la force magnétique et la fixation de longueurs de barres dans certains domaines. Étant donné que les matériaux qu'il manipule varient, la structure de l'électroaimant, le circuit magnétique et les processus de fabrication diffèrent également, ce qui donne lieu à de nombreuses séries de produits ciblés avec des forces et des capacités spécifiques.

À propos de nous

Électroaimant de levage avec différentes capacités

Le granulateur BSGH ne produit pas seulement toutes sortes de machines de recyclage de déchets de cuivre, mais sert également nos clients avec des produits périphériques de levage électromagnétique pour augmenter l'efficacité de la machine et faciliter le fonctionnement du client.

Dans le domaine des opérations industrielles, la manutention et le transport de diverses matières premières présentent des défis redoutables. Bon nombre de nos clients sont confrontés à des complexités importantes en raison de la diversité des matières premières qu'ils manipulent, de taille, de type et de caractéristiques variables. Nos électroaimants de levage sont méticuleusement conçus pour répondre spécifiquement à ces défis, offrant une solution efficace qui minimise les préoccupations des clients et optimise l'efficacité opérationnelle. En tirant parti de notre technologie, les clients atteignent sans effort leurs objectifs, en gérant efficacement les subtilités liées à la manutention des matériaux.

Au cœur de notre mission se trouve un engagement inébranlable à donner du pouvoir à nos clients dans tous les secteurs. Avec nos électroaimants spécialisés comme pierre angulaire, notre objectif reste inébranlable : simplifier le domaine complexe de la manutention des matériaux. Nous aspirons à être la force motrice qui propulse nos clients vers un succès inégalé dans leurs diverses activités industrielles.

types d'électroaimants de levage

Les ascenseurs électromagnétiques, avec leurs différents types, formes et configurations, répondent à des applications spécifiques dans divers secteurs. Cette polyvalence souligne leur efficacité pour répondre aux besoins spécifiques de chaque secteur, mettant en valeur la nature adaptable de la technologie magnétique pour répondre aux exigences spécialisées de tous les secteurs.

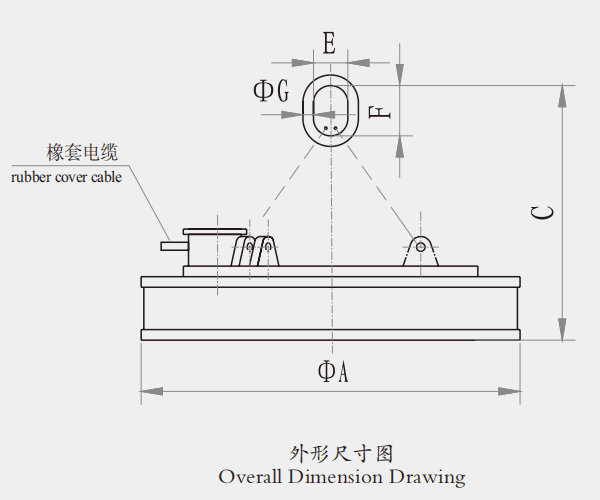

Données techniques de l'électroaimant de levage de ferraille

Il existe également des types haute température, des types haute fréquence, des électro-aimants de levage de forme ovale, des électro-aimants de levage pour billettes, billettes de poutres et dalles, etc.

Convient pour les lingots coulés, les billes d'acier, la fonte brute, les copeaux de machine, pour divers types de ferrailles d'acier, les ferrailles de retour, les déchets de récolte, les déchets de mise en balles, etc. dans les usines de fonderie et pour la poudre de fer dans les laveurs de charbon. Pendant le processus d'élimination des scories, il peut éliminer la grande taille de fer à l'étape initiale. Le boîtier de sortie comporte deux chambres, un garde-boue extra épais et un réglage anti-torsion. Il existe trois options d'excitation : tension nominale DC220V ; forte

excitation; surexcitation.

| Modèle | Puissance à froid (KW) | Courant (état froid/chaud) | Poids (kg) | Dimensions hors tout | Capacité de levage (état froid/chaud) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| UN | C | F | E | G | Bille d'acier | Lingot de coulée | Tournages | ||||||

| BS5-50L-1 | 2.6 | 11.8/7.7 | 220 | 500 | 700 | 160 | 90 | 25 | 1200 | 220/130 | 80/65 | ||

| BS5-60L/1 | 3.0 | 13.6/8.9 | 320 | 600 | 750 | 160 | 90 | 25 | 2000 | 290/170 | 95/80 | ||

| BS5-70L/1 | 3.3 | 15/9.8 | 490 | 700 | 800 | 160 | 90 | 30 | 2500 | 380/200 | 120/100 | ||

| BS5-80L/1 | 4 | 18/12 | 580 | 800 | 800 | 160 | 90 | 30 | 3000 | 480/250 | 150/130 | ||

| BS5-90L/1 | 5.9 | 26.8/17.5 | 750 | 900 | 1090 | 200 | 125 | 40 | 4500 | 600/400 | 250/200 | ||

| BS5-110L/1 | 7.7 | 35/22.8 | 1100 | 1100 | 1140 | 220 | 150 | 40 | 6500 | 1000/800 | 450/400 | ||

| BS5-120L/1 | 10 | 45.5/29.5 | 1300 | 1200 | 110 | 220 | 150 | 45 | 7500 | 1300/100 | 650/500 | ||

| BS5-130L/1 | 12 | 54.5/35.5 | 1700 | 1300 | 1240 | 250 | 175 | 50 | 8500 | 1400/1100 | 700/600 | ||

| BS5-150L/1 | 15.6 | 70.9/46.1 | 2200 | 1500 | 1250 | 350 | 210 | 60 | 11000 | 1900/1500 | 1100/900 | ||

| BS5-165L/1 | 16.5 | 75/48.8 | 2700 | 1650 | 1590 | 370 | 230 | 75 | 12500 | 2300/1800 | 1300/1100 | ||

| BS5-180L/1 | 22.5 | 102.3/66.5 | 3200 | 1800 | 1490 | 370 | 230 | 75 | 14500 | 2750/2100 | 1600/1350 | ||

| BS5-210L/1 | 28.4 | 129/84 | 4200 | 2100 | 1860 | 400 | 25 | 80 | 21000 | 3500/2800 | 2200/1850 | ||

| BS5-240L/1 | 33.9 | 154/100 | 5500 | 2400 | 2020 | 450 | 280 | 90 | 26000 | 4800/3800 | 2850/2250 | ||

| BS5-260L/1 | 35.6 | 162/105 | 6800 | 2600 | 2100 | 450 | 280 | 90 | 30000 | 6100/4900 | 3850/3600 | ||

| BS5-280L/1 | 39 | 178/116 | 7900 | 2800 | 2700 | 500 | 300 | 100 | 34000 | 7100/5700 | 4450/3400 | ||

| BS5-300L/1 | 41.6 | 189/123 | 11000 | 3000 | 2300 | 500 | 300 | 100 | 39000 | 8350/6700 | 5250/4100 | ||

Cet électroaimant est conçu pour des opérations à température standard. Pour des exigences spécifiques telles que des applications à haute température ou à haute fréquence, n'hésitez pas à nous contacter pour des solutions sur mesure et une assistance supplémentaire.

caractéristiques de l'électroaimant de levage

- Adopter une structure totalement étanche avec une bonne propriété d'étanchéité à l'humidité. Initiative nationale de protection non magnétique, production de plaques en acier inoxydable, isolation magnétique, résistance à l'usure et aux chocs.

- La technologie étrangère a été introduite, améliorée, innovée, ainsi qu'une conception optimale par ordinateur pour rendre nos produits avec une structure raisonnable, un poids propre léger, une forte force d'attraction et une faible consommation d'énergie.

- Les bobines d'énergie ont été traitées par une technologie spéciale et ainsi leurs propriétés électriques et mécaniques sont améliorées, la résistance à la chaleur du matériau isolant atteint le grade C et la durée de vie est longue.

- Le cycle de service nominal d'un électro-aimant normal est passé de 50% à 60%, ce qui améliore l'efficacité de travail.

- L'électroaimant à haute température adopte une isolation unique contre la chaleur et le rayonnement, la température des matériaux attachés passe de 600° C dans le passé à 700° C, ce qui élargit la plage d'application de l'électroaimant.

- Un ensemble complet d'unités auxiliaires telles qu'une cabine de commande, un enrouleur de câble, etc. peut également être fourni.

- L'installation, l'utilisation et la maintenance sont pratiques

Comment choisir un électro-aimant ?

- Les spécifications, le tonnage, la hauteur du palan, le type de frein du crochet et la capacité doivent être fournis.

- Choisissez le type de température normal, élevé ou très élevé en fonction de la température du matériau. Si la température est inférieure à 150 °C, choisissez le type normal ; entre 150 °C et 600 °C, le type élevé ; au-dessus de 600 °C mais avec une limite inférieure à 700 °C, le type très élevé.

- Cycle de service : lorsque vous dépassez 60%, choisissez le type haute fréquence.

- Lorsque l'opération est en liquide, veuillez choisir le type de plongée et nous fournir le milieu liquide et la profondeur de plongée.

- Veuillez fournir les paramètres de géométrie (tels que la longueur, la largeur, la profondeur, le diamètre, etc.) et le nombre de pièces ou de paquets à soulever lors du levage de matériaux de section et de matériaux en feuille.

- Pour une unité simple, choisissez l'armoire de commande et les autres équipements auxiliaires en fonction de la puissance consommée (courant) ; pour l'unité combinée, nous avons besoin de la quantité totale de puissance consommée (courant).

- La hauteur de levage détermine la longueur du câble enroulé sur l'enrouleur de câble. La puissance de l'électroaimant (courant) détermine la tolérance de courant de l'enrouleur de câble. Les pièces des électroaimants et les conditions de groupement déterminent le nombre de noyaux.

Comprendre les électroaimants de levage de ferraille

Évolution et innovation

L'histoire des électroaimants de levage de ferraille remonte au 19e siècle. Au départ, des configurations de base étaient utilisées, mais les progrès technologiques ont conduit à des modèles très sophistiqués. L'évolution a été marquée par des capacités de levage et une efficacité opérationnelle améliorées.

Comment fonctionnent les électro-aimants en ferraille ?

Ces électroaimants utilisent des champs électromagnétiques générés par des courants électriques. Le passage du courant à travers une bobine de fil crée un champ magnétique. Lorsque l'électricité est activée, l'aimant attire les matériaux ferreux. Une fois le courant arrêté, le champ magnétique diminue, libérant la charge.

Avantages dans les applications industrielles

Efficacité dans la manutention des matériaux

Les électroaimants de levage de ferraille sont parfaits pour la manutention de matériaux ferreux lourds et de formes irrégulières. Leur force magnétique assure une préhension et un transport sûrs, ce qui simplifie considérablement les processus opérationnels.

Sécurité et rentabilité

Ces électroaimants contribuent à un environnement de travail plus sûr en réduisant le besoin de manutention manuelle. De plus, ils minimisent les dommages matériels, ce qui se traduit par des économies de coûts en préservant l'intégrité des marchandises transportées.

Composants et configuration

Un électroaimant de levage de ferraille typique comprend un noyau ferreux, une bobine enroulée autour de celui-ci et une source d'alimentation. L'agencement est conçu pour optimiser le champ magnétique pour un levage efficace du matériau.

Applications dans tous les secteurs

Installations de recyclage des métaux

Les électroaimants de levage de ferraille jouent un rôle essentiel dans les opérations de recyclage. Ils séparent et transportent efficacement les déchets métalliques, contribuant ainsi aux pratiques durables et à la conservation des ressources.

Chantiers de construction et de démolition

Dans le domaine de la construction, ces électroaimants permettent de déplacer des poutres et des structures en acier lourdes. De même, dans le domaine de la démolition, ils aident à éliminer les débris en soulevant rapidement les morceaux de métal.

Lignes de fabrication et d'assemblage

Les unités de fabrication utilisent ces électroaimants pour la manutention des matériaux au cours des différentes étapes de la production. Leur précision et leur efficacité rationalisent le processus d'assemblage.

FAQ sur l'électroaimant de levage

Les électroaimants de levage de ferraille, lorsqu'ils sont utilisés conformément aux consignes de sécurité, sont considérés comme sûrs. Cependant, il faut faire preuve de prudence pour éviter les accidents.

Absolument ! Leur force magnétique permet de soulever des matériaux ferreux très divers, quelles que soient leurs formes et leurs dimensions.

Le plus souvent, ils fonctionnent à l’électricité, mais des configurations spécifiques peuvent être personnalisées pour s’adapter à des sources d’énergie alternatives.

Des contrôles de routine de l'usure, de la détérioration et du bon fonctionnement sont essentiels. Les tâches de maintenance peuvent inclure l'inspection de la bobine, la vérification des connexions et la garantie de la stabilité de la source d'alimentation.

Bien que certaines variantes soient conçues pour une utilisation sous-marine, les modèles standards peuvent être confrontés à des limitations opérationnelles lorsqu'ils sont immergés.

Tenez compte de facteurs tels que la capacité de levage, la compatibilité de la source d’alimentation et l’environnement opérationnel lors de la sélection de l’électro-aimant approprié.