Máquinas de sucata de cobre de alta qualidade da China

Uma máquina de sucata de cobre é um equipamento usado para processar vários tipos de sucata de cobre. Sua principal função é separar o cobre de outros materiais de sucata para atingir o propósito de reciclagem.

Geralmente dividimos máquinas de sucata de cobre em máquinas de decapagem de fios e máquinas de granulação de fios de cobre, máquinas de reciclagem de motores de sucata e máquinas de reciclagem de radiadores. Nós projetamos máquinas de reciclagem de sucata de cobre multifuncionais e uma variedade de modelos de acordo com as diferentes características das máquinas. Cada máquina de sucata de cobre tem suas características únicas e desempenha um papel importante na indústria de reciclagem.

Melhores máquinas de sucata de cobre da China

Aqui estão quatro tipos de máquinas de sucata de cobre fabricadas pela BSGH Granulator que podem ser usadas para reciclar materiais de sucata de cobre: máquina de decapagem de fios de cobre, máquina granuladora de cobre, máquina de reciclagem de motor elétrico e máquina de decapagem de radiador de sucata. Cada máquina de sucata de cobre tem suas características únicas e desempenha um papel importante em sua indústria de reciclagem. A parte a seguir é uma exibição do produto de cada máquina. Você pode clicar no botão abaixo de cada máquina para saber mais sobre seus detalhes.

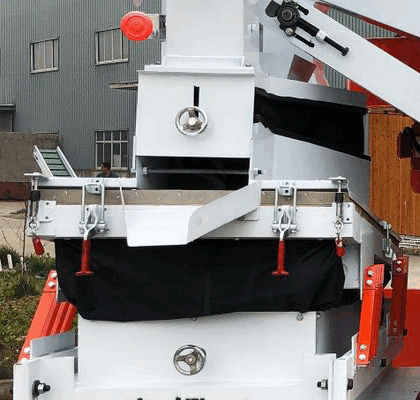

Informações sobre a máquina de decapagem de fios de cobre

Nossas máquinas de decapagem de fios de cobre são principalmente destinadas a grandes cabos blindados ou cabos de grande diâmetro. Elas têm uma estrutura resistente, bela aparência e podem decapagem de fios de até 200 mm. Seja uma operação de pequena escala ou um grande projeto industrial, nossas máquinas de decapagem de fios de cobre podem fornecer excelente suporte de desempenho para garantir processos de reciclagem eficientes e sustentáveis para vários materiais.

Descrição do produto

Modelo | Diâmetro | Peso (KG) | Potência (KW) | Dimensão (MM) |

BS-AC80 | 2-72MM | 152 | 3 kW | C520*L740*A890 |

BS-KOF | 1,5-50 mm | 115 | 3 kW | C760*L640*A920 |

BS-AC120 | 10-120MM | 205 | Caixa de redução de 3 kW | C710*L510*A1130 |

BS-AC55 | 2-50MM | 122 | 2,2 kW | C780*L595*A987 |

BS-AN120 | 15-120MM | 185 | Caixa de redução de 3 kW | C600*L50*A1250 |

Máquina de decapagem de fios de alta venda

Abaixo estão as máquinas de decapagem de fios de cobre de alta qualidade da nossa empresa, todas elas têm desempenho estável. Você pode clicar diretamente no link do produto abaixo para saber mais sobre os detalhes específicos da máquina, nós garantimos que você obtenha a mais alta qualidade e o menor preço.

Vantagens da máquina de decapagem de fios de cobre

Melhore a eficiência do decapagem de fios

A máquina de decapagem de fios de cobre pode simplificar o tedioso processo de decapagem de fios em etapas simples, o que não só economiza muito tempo, mas também permite que a mão de obra se concentre em trabalhos mais importantes e melhore a eficiência geral do trabalho.

Durável e econômico

O preço da máquina de decapagem de fios é relativamente baixo, o que é mais econômico do que contratar vários trabalhadores. Ao mesmo tempo, a máquina de decapagem de fios tem uma longa vida útil e pode ser usada por muitos anos com manutenção adequada.

Fácil de operar

O uso da máquina de decapagem de fios não requer ajustes complicados, é fácil de operar e você pode começar rapidamente. E o design e a fabricação da máquina de decapagem de fios levam em consideração a conveniência do usuário, tornando o processo de operação mais suave.

Forte adaptabilidade

A máquina de decapagem de fios é altamente adaptável e pode lidar com fios de diferentes tipos e especificações, quase atendendo às necessidades de várias especificações. Sejam fios residenciais, cabos de escritório ou fios industriais, a máquina de decapagem de fios pode processá-los.

No vídeo a seguir, você pode ver com mais clareza todo o processo de funcionamento da nossa máquina de decapagem de fios.

Raw Materials & Applications

O que podemos processar

Para qual indústria somos adequados

A máquina de decapagem de fios de cobre da BSGH Granulator pode lidar com fios grossos com diferentes diâmetros de cabo, como fio de núcleo único, fio multi-núcleo, fio de alumínio, cabo de folha de arame, cabo blindado, cabo de alta tensão, cabo óptico, cabo submarino, bainha fio plano, fio de aço, etc.

A máquina de decapagem de fios pode ser amplamente utilizada em produção de arame, produtos eletrônicos, fiação elétrica de construção, reciclagem de sucata de cabos e outras indústrias.

Dicas de manutenção

Lubrificação regular

De acordo com a frequência de uso do decapador de fios de cobre, aplique uma quantidade adequada de óleo lubrificante ou graxa nas peças deslizantes e rolamentos regularmente para manter sua flexibilidade e operação suave.

Verifique as lâminas regularmente

Verifique regularmente se as lâminas da máquina de decapagem de fios de cobre estão gastas ou danificadas. Se necessário, substitua as lâminas a tempo para garantir o efeito de decapagem e a segurança do decapador de fios.

Armazenamento e preservação

Quando nossa máquina de decapagem de fios de cobre não estiver em uso, ela deve ser armazenada em local seco e ventilado para evitar umidade ou danos causados por objetos externos.

Precauções de segurança

Ao descascar fios, evite usar fios diversos ou fios descartados com plugues.

peça um orçamento grátis agora!

Como uma empresa líder na produção de máquinas de reciclagem de sucata de cobre, estamos sempre comprometidos em melhorar a qualidade de nossas máquinas para melhor atender às suas necessidades exclusivas. Se você precisar de assistência para selecionar a máquina certa para suas operações ou tiver dúvidas sobre nossa máquina específica, nossa equipe profissional está aqui para apoiá-lo em cada etapa do caminho.

Este formulário é totalmente seguro, então não se preocupe e envie um e-mail para nos contar suas necessidades de decapagem de cabos de cobre. Responderemos a você em até 2 horas.

máquina de sucata de cobre - Granuladores de cobre

O máquina de granulação de sucata de cobre da nossa empresa representa uma tecnologia avançada líder para processamento de cabos residuais no mercado. A operação começa com o triturador principal, que tritura os cabos residuais em partículas misturadas de cobre e plástico. Em seguida, um separador de ar e uma mesa vibratória trabalham juntos para separar as partículas misturadas. Este processo de separação em duas etapas garante o isolamento eficaz dos materiais. O resultado final são partículas de cobre puro e partículas de plástico puro.

Descrição do produto

Modelo | Capacidade | Peso (KG) | Potência (KW) | Dimensão (MM) |

BS-D75 | 70 kg/h | 1500 | 18 kW | C1700*L1600*A2200 |

BS-D10 | 100 kg/h | 1800 | 24 kW | C2230*L1600*A2000 |

BS-D30 | 300 kg/h | 3500 | 37,2 kW | C2700*L2100*A2300 |

BS-D65 | 500 kg/h | 4000 | 53 kW | C4200*L2250*A2850 |

ECO1000 | 700-1200 kg/h | 5800 | 76 kW | C7200xL7500xA2200 |

Granuladores de cobre de venda quente da BSGH Granulator

Abaixo estão as máquinas granuladoras de cobre mais vendidas da nossa empresa, que têm estrutura sólida, motor de cobre puro altamente confiável e lâminas de liga especial com boa resistência ao desgaste. Usar uma máquina de arroz de cobre pode obter cobre puro 100%

-

Máquina de corte de sucata BS-D20 totalmente automática, fábrica de 200 kg/h

Ler mais -

Melhor Custo Desempenho BS-D60 Máquina Separadora de Fios de Cobre em Venda

Ler mais -

Máquina de reciclagem de cobre BS-N125 com separador eletrostático para cabos de sucata

Ler mais -

Máquina trituradora de cabos BS-N130 de 400 a 700 kg/h mais vendida para venda

Ler mais -

Granuladores de cabo de cobre industrial de grande capacidade para venda BS-F3000

Ler mais

Vantagens da máquina granuladora de cobre

Benefícios econômicos significativos

Os recursos de cobre em fios e cabos de sucata são de alto valor. Você pode usar nossos granuladores de cobre de forma eficiente para recuperar os recursos de cobre, assim você pode confiar neles para obter mais dinheiro para viver a vida.

Operação simples e eficiente

O preço da máquina de decapagem de fios é relativamente baixo, o que é mais econômico do que contratar vários trabalhadores. Ao mesmo tempo, a máquina de decapagem de fios tem uma longa vida útil e pode ser usada por muitos anos com manutenção adequada.

Ampla faixa de processamento

Os granuladores de cobre podem processar fios de cobre de sucata de diferentes especificações e também podem processar cabos de sucata mistos de diferentes diâmetros.

Excelente qualidade

A BSGH Granulator fabrica suas máquinas usando materiais de alta qualidade e em conformidade com os mais altos padrões da indústria. Também testamos a qualidade das máquinas muitas vezes durante a produção, garantindo que cada máquina tenha durabilidade e longevidade.

Quais partes da máquina granuladora de cobre você pode montar?

As máquinas granuladoras de cobre para sucata de fio de cobre têm pequenas máquinas individuais ou linhas de reciclagem completas. As máquinas individuais pequenas têm máquinas de decapagem de sucata de fio de cobre e máquinas granuladoras individuais; para uma linha de reciclagem completa, podemos escolher montar diferentes configurações de acordo com as solicitações do cliente.

a parte obrigatória

Triturador

O triturador é a peça principal, usada principalmente para triturar sucata de fio de cobre em pequenos grânulos mistos de arroz de cobre e plástico para a próxima etapa de preparação.

sistema separador de ar

O sistema separador de ar é uma parte crucial para separar grânulos de cobre e plástico.

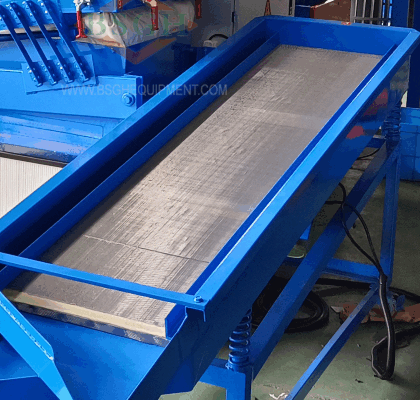

vibrador de mesa

A pequena máquina vibradora de mesa tem 2 tipos, uma é para saída de cobre e outra é para saída de plástico, elas não são iguais.

configurações opcionais

Os clientes podem escolher diferentes configurações de máquinas de acordo com os tipos de fios de sucata de cobre que processam; para diferentes tipos de matéria-prima, as máquinas precisam montar peças diferentes.

pré-triturador

Vários trituradores para opções.

Temos desde trituradores pequenos até grandes para você escolher, desde trituradores de motor único de 3 kW até grandes trituradores industriais de motor duplo de 132 kW*2. Entre em contato com nossa equipe.

separador eletrostático

Se você tiver fios finos, fios de cabelo ou fios muito pequenos, recomendamos que você monte um separador eletrostático para seu granulador.

Separador magnético de camada dupla

Uma máquina separadora magnética de camada dupla é configurada após a saída de cobre, a função principal é absorver os pequenos metais em grânulos de cobre.

Etapas de trabalho dos granuladores de cobre

O primeiro pré-triturador tritura os cabos em pedaços de 5 a 25 cm.

Por meio de um transportador, os cabos triturados são transportados para o triturador principal, que os tritura novamente em pedaços de plástico de 3 a 5 mm de comprimento e grânulos de cobre.

A mistura é enviada para o sistema de vibração. Por meio do separador de gravidade de fluxo de ar e da tela de vibração, as peças de plástico são separadas dos grânulos de cobre completamente.

Grânulos de cobre e partículas de plástico saem de diferentes saídas.

Raw Materials & Applications

O que podemos processar

Para qual indústria somos adequados

Nossos granuladores de cobre podem processar vários cabos, incluindo fios de eletrodomésticos, fios de comunicação, fios de computador, fios grossos, fios de tear automotivo, etc.

A máquina granuladora de cobre é amplamente utilizada em estações de reciclagem de resíduos, plantas de processamento de metais, indústria automotiva, fabricantes de cabos, etc. devido à sua alta eficiência de processamento.

Dicas de manutenção

Os rolamentos de todas as peças de corrida da nossa máquina granuladora de cobre foram preenchidos com graxa antes de sair da fábrica, mas isso é limitado ao equipamento de depuração. Ao usar oficialmente a máquina granuladora de cobre, os rolamentos de todas as peças de corrida devem ser preenchidos novamente com graxa. Cada peça de corrida deve ser preenchida com graxa nova a cada 40 horas de operação, e os mancais do britador devem ser preenchidos com graxa nova a cada 8 horas de operação.

A lâmina ficará cega após um período de produção, o que afetará os efeitos de trituração e classificação, por isso ela precisa ser polida de vez em quando.

Ao polir a lâmina, você deve escolher polimento mecânico. A lâmina ficará mais estreita após polimento repetido. Quando a folga entre a lâmina rotativa e a lâmina fixa do invólucro não puder atender aos requisitos de esmagamento, a lâmina antiga precisará ser substituída.

Ao polir ou substituir a lâmina, desligar a potência antes de operar. Ajuste a folga entre a lâmina rotativa e a lâmina fixa toda vez que polir ou substituir a lâmina.

obter orçamento grátis

Obtenha os melhores preços de máquinas granuladoras de fio de cobre hoje. O valor da nossa marca é permitir que os clientes comprem a máquina mais satisfatória pelo preço mais adequado. Entre em contato conosco hoje para um orçamento personalizado e obtenha máquinas granuladoras de fio de cobre líderes do setor.

Máquina de sucata de cobre | Motores de sucata de reciclagem

Ao reciclar e reutilizar os enrolamentos de cobre em motores de sucata, o consumo de matérias-primas é reduzido, o custo de produção de novos motores é reduzido e a poluição de resíduos para o meio ambiente também é reduzida. A aplicação e promoção desta tecnologia é de grande importância para promover a economia circular e o desenvolvimento sustentável.

Descrição do produto

Modelo | Capacidade (PCS/H) | Peso (KG) | Potência (KW) | Dimensão (MM) |

BSM-10 | 50-70 | 750 | 5,5 kW | C2400*L1100*A1300 |

BSM-30 | 60-80 | 395 | 5,5 kW | C2310*L770*A950 |

BSM-40 | 0-120 | 670 | 7,5 kW | C1940*L1430*A1150 |

BSM-50 | 40-60 | 650 | 7,5 kW | C2140*L800*A730 |

BSM-60 | 80-120 | 508 | 4 kW | C1370*L1040*A1460 |

BSM-70 | 200-300 | 430 | 3 kW | C1500xL650xA800 |

Melhor máquina de decapagem de motor elétrico

Abaixo estão as máquinas de decapagem de motor elétrico de alta qualidade da nossa empresa, todas elas têm desempenho estável. Você pode clicar diretamente no link do produto abaixo para saber mais sobre os detalhes específicos da máquina.

Máquina de reciclagem de motores BSM-10

Máquina de reciclagem de motores BSM-30

Máquina de reciclagem de motores BSM-40

Máquina de reciclagem de motores BSM-50

Máquina de reciclagem de motores BSM-60

Máquina de reciclagem de motores BSM-70

Vantagens da máquina de reciclagem de sucata de motor

Sistema hidráulico

Nossa máquina de decapagem de motor elétrico é equipada com sistema de corte hidráulico e sistema de tração, que pode facilmente cortar o estator do motor e puxar os enrolamentos de cobre do motor. Os enrolamentos de cobre podem ser puxados todos de uma vez, o que torna a eficiência de processamento da máquina maior.

Materiais de alta qualidade

As lâminas da maioria das peças de corte de nossas máquinas são feitas de liga de aço com alto teor de manganês, com resistência ao desgaste, alta dureza e boa tenacidade, o que pode garantir uma longa vida útil e durabilidade das máquinas.

Fornecendo retornos econômicos

O custo de reciclagem de motores descartados é relativamente baixo e a demanda do mercado é muito forte, então iniciar um negócio nessa área geralmente pode obter retornos de lucro maiores.

Fácil operação

A máquina de reciclagem de motores é muito fácil de operar e requer apenas um operador para concluir a operação, o que pode economizar muito em custos de mão de obra.

Etapas de trabalho da máquina de reciclagem de agitação de motor de sucata

Tente colocar uma extremidade do enrolamento de cobre do motor sob a faca de corte. Em seguida, o operador deve girar o motor manualmente após cada corte até que o enrolamento de cobre esteja totalmente cortado.

Em seguida, coloque o estator na parte de puxar cobre para separar os enrolamentos de cobre e o aço silício. Nota: Você deve colocar o estator em

Raw Materials & Applications

O que podemos processar

Para qual indústria somos adequados

Existem algumas matérias-primas que podem ser processadas pela nossa máquina de reciclagem de motores:

As máquinas de reciclagem de motores podem ser amplamente utilizadas em empresas de manufatura, empresas de transporte, empresas agrícolas, usinas de reciclagem de motores, etc.

Dicas de manutenção

-

Dica 1

Antes de usar a máquina, verifique se a caixa elétrica está inundada ou úmida.

-

Dica 2

Verifique a tomada elétrica e a capa protetora. Se ocorrer algum dano, substitua-a a tempo.

-

Dica 3

Há duas pistas de corrida em ambos os lados do cortador, que precisam ser lubrificadas e mantidas pelo menos duas vezes por dia.

-

Dica 4

Quando as garras se retraem, há várias pistas de rolamento na máquina, e óleo lubrificante deve ser adicionado para manutenção pelo menos duas vezes ao dia.

-

Dica 5

Quando o tanque de óleo hidráulico estiver em uso, adicione óleo até 2/3 do tanque.

Preço e ROI da máquina de decapagem de motor elétrico

Cada máquina é personalizada para sua situação, portanto os preços e o ROI podem variar.

Entre em contato conosco para obter um orçamento exclusivo.

máquina de sucata de cobre | reciclar sucata Radiadores

Os radiadores de sucata consistem em folhas de alumínio e tubos de cobre, vêm de sucatas de carros, tanques de água e condicionadores de ar, a principal vantagem técnica da máquina de reciclagem de radiadores está em sua capacidade de processamento de radiadores de sucata. Nossa empresa tem principalmente dois tipos de equipamentos para reciclagem de radiadores, a saber, máquina de stripper de radiador e linha de produção de reciclagem de radiador.

A máquina stripper de radiador é para separar tubos de cobre e folhas de alumínio nos radiadores de sucata, realizando a recuperação dupla de alumínio e cobre. Esta máquina tem as características de baixo investimento e alta eficiência. Enquanto isso, a linha de produção de reciclagem de radiadores da nossa empresa divide três tipos: triturador de radiador de eletrodomésticos, usina de reciclagem de radiador de tanque de água e máquina de reciclagem de radiador de carro.

A principal vantagem técnica da máquina de reciclagem de radiadores está na sua capacidade de processamento de radiadores de sucata. Por meio deste equipamento, materiais de alumínio e cobre podem ser efetivamente recuperados para atingir a reutilização de recursos, ao mesmo tempo em que reduz os custos de processamento e melhora a eficiência da utilização de recursos.

Vantagens da máquina de reciclagem de radiadores

Alto desempenho de custo

As máquinas de reciclagem de radiadores da BSGH Granulator são muito acessíveis e podem descascar e separar todos os tipos de radiadores, como radiadores de ar condicionado, radiadores de carro, etc., para reciclar cobre e alumínio. Você só precisa de um pequeno investimento para obter um retorno enorme.

Ampla faixa de processamento

A máquina de reciclagem de radiadores da BSGH Granulator pode processar uma ampla gama de distâncias centrais de tubos de cobre. Podemos processar materiais de radiadores com distâncias centrais de 17,5 mm, 19 mm, 21 mm, 22 mm e 25 mm. Claro, também oferecemos suporte a serviços personalizados. Se você tiver requisitos para outros tamanhos, entre em contato conosco e os personalizaremos para você.

Alta eficiência

A máquina de reciclagem de radiadores da BSGH Granulator tem uma capacidade de processamento muito poderosa, e a estrutura perfeita das lâminas faz com que a máquina decapadora de radiadores melhore essencialmente a eficiência da reciclagem de cobre.

Fácil operação

Você só precisa alinhar a borda do radiador com o thermovent e, em seguida, empurrar o radiador para dentro da porta de alimentação. A engrenagem de alimentação prenderá firmemente o radiador e concluirá automaticamente todo o processo de separação.

Etapas de trabalho da máquina de decapagem de radiador

Gire o interruptor de reversão e verifique a direção de rotação.

Injete óleo nos dois orifícios de óleo nos lados esquerdo e direito da máquina para lubrificar as engrenagens da transmissão (geralmente uma vez a cada 4 horas de trabalho).

Empurre diferentes radiadores de cobre e alumínio em diferentes entradas de material de acordo com suas especificações (19 mm, 21 mm, 25 mm) para separação; o lado esquerdo dos radiadores deve tocar o lado esquerdo das entradas de material; quando os radiadores são empurrados para as entradas de material, as engrenagens de alimentação irão roer os radiadores e levá-los para dentro da máquina.

Depois que os radiadores são levados para dentro do dispositivo, os tubos de cobre e alumínio são separados e saem da máquina automaticamente.

De acordo com as camadas dos radiadores e sua altura, ajuste cada par de Rodas de Ajuste na máquina (após o ajuste, aperte os parafusos abaixo).

Raw Materials & Applications

O que podemos processar

Para qual indústria somos adequados

Aqui estão algumas fotos do radiador para mostrar a você: plano e sem curvas

A máquina de decapagem de radiadores pode ser usada em estações ou fábricas de reciclagem de radiadores, plantas de processamento de metais, indústria da construção, reciclagem de radiador de automóvel, fundições, etc.

Notas antes de trabalhar

Verifique se a energia está bem conectada;

Verifique se as Réguas Guia de cada peça estão na posição correta;

Verifique se as duas rodas de ajuste de cada par estão no mesmo nível;

Ligue a máquina e verifique se ela está funcionando na direção correta.

Contate-nos

Como um fabricante líder especializado na produção de máquinas de decapagem de radiadores, sempre oferecemos soluções de alta qualidade, personalizadas de acordo com suas necessidades específicas.

Quer você precise de assistência sobre a introdução de máquinas ou tenha dúvidas sobre matérias-primas, nossa equipe profissional está aqui para apoiá-lo com a maior sinceridade.

Seu fabricante confiável de máquinas de reciclagem de sucata de cobre

A BSGH Granulator é a melhor fábrica de máquinas para reciclagem de sucata de cobre na China. Atendemos o mercado de reciclagem de cobre há mais de 25 anos.

Nossa empresa adere ao conceito de inovação tecnológica, qualidade em primeiro lugar e gestão honesta. Ela tem uma equipe de pesquisa e desenvolvimento de engenheiros seniores e pessoal de gestão, e está comprometida em criar produtos de marca mundialmente famosos. Os produtos da nossa empresa são vendidos no país e no exterior, atendendo às necessidades de alta qualidade dos países europeus e americanos. Além disso, a empresa também fornece forte suporte técnico e serviço pós-venda de alta qualidade, e fornece produtos de alta qualidade para clientes em todo o país e ao redor do mundo.

BSGH Granulator - Seu parceiro mais confiável

Sua solução definitiva para equipamentos de máquina de sucata de cobre eficientes e ecológicos – a melhor máquina de sucata de cobre da China

Venha e aproveite uma viagem de RA para BSGH ➜

Feedback do cliente

Todas as máquinas que vendemos passam por inspeção de qualidade porque fomos verificados pelo mercado e reconhecidos por organizações relevantes, e os clientes elogiam muito nossas máquinas depois de usá-las.

o que você pode obter de nós?

O mundo continua girando. Neste mercado de reciclagem em rápido desenvolvimento, aderimos ao espírito que buscamos. Por meio dessa persistência, encontramos nosso lugar e continuamos a nos desenvolver. Acreditamos que tecnologia, inovação, integridade e desenvolvimento mútuo são as direções que buscamos.

A tecnologia é a força motriz para a sobrevivência e o desenvolvimento de uma empresa. A BSGH Granulator tem sua tecnologia e produtos principais. Isso determina a posição de liderança e a vantagem absoluta da nossa empresa na competição de mercado.

Inovação inclui inovação de gestão, inovação tecnológica e inovação de serviço. A BSGH ouve as opiniões dos clientes com uma mente aberta e melhora sua tecnologia de fabricação e conscientização de serviço. Nós nos promovemos e nos fortalecemos no processo de desenvolvimento.

Integridade é a base de uma empresa. Somente uma empresa honesta pode se desenvolver por um longo tempo. A BSGH Granulator atribui grande importância ao espírito de integridade. Estamos ansiosos para cooperar com você com total sinceridade.

Nossos clientes nos apoiam, e nós os retribuímos com produtos de alta qualidade e serviços atenciosos. Estamos comprometidos em alcançar resultados ganha-ganha para nossos clientes, funcionários e a empresa.

Escolha múltipla | Soluções completas

Entre em contato conosco e nós o ajudaremos a criar lucro

Temos uma equipe técnica profissional, equipe de serviço para fornecer um serviço completo de consultoria, design, planejamento, fabricação, instalação para todos os tipos de máquinas de sucata de cobre. Se você tiver alguma necessidade, pode entrar em contato conosco diretamente.

Deixe suas dúvidas aqui para obter o que lhe interessa.