High Quality Copper Scrap Machines From China

A copper scrap machine is an equipment used to process various types of scrap copper contain materials. Its main function is to separate the copper from other scrap materials to achieve the purpose of recycling.

We usually divide copper scrap machines into wire stripping machines and copper wire granulating machines, scrap motor recycling machines and radiator recycling machines. We have designed multifunction copper scrap recycling machine and a variety of models according to the different features of machines. Each copper Scrap machine has its unique features and plays an important role in the recycling industry.

Best Copper Scrap Machines From China

Here are four kinds of copper scrap machines manufactured by BSGH Granulator can use to recycle scrap copper materials: copper wire stripping machine, copper granulator machine, electric motor recycling machine and scrap radiator stripper machine. Each copper scrap machine has its unique features and plays an important role in their recycling industry. The following part is a product display of each machine. You can click the button under each machine to learn more about its detail.

Information About copper Wire Stripping Machine

Our copper wire stripping machines are mainly aimed at large armored cables or big diameter cables. They have a sturdy structure, beautiful appearance and can strip wires up to 200mm. Whether it is a small-scale operation or a large industrial project, our copper wire stripping machines can provide excellent performance support to ensure efficient and sustainable recycling processes for various materials.

Product Description

Model | Diameter | Weight(KG) | Power(KW) | Dimension(MM) |

BS-AC80 | 2-72MM | 152 | 3KW | L520*W740*H890 |

BS-KOF | 1.5-50MM | 115 | 3KW | L760*W640*H920 |

BS-AC120 | 10-120MM | 205 | 3KW Reduction Gear Box | L710*W510*H1130 |

BS-AC55 | 2-50MM | 122 | 2.2KW | L780*W595*H987 |

BS-AN120 | 15-120MM | 185 | 3KW Reduction Gear Box | L600*W50*H1250 |

Hot sales Wire Stripping Machine

Below are our company’s high quality copper wire stripping machines, all of them have stable performance. You can directly click on the product link below to learn more about the specific details of the machine, we ensure you get the highest quality and lowest price.

Advantages of copper Wire Stripping Machine

Improve wire stripping efficiency

The copper wire stripping machine can simplify the tedious wire stripping process into simple steps, which not only saves a lot of time but also allows manpower to focus on more important work and improve overall work efficiency.

Durable and economical

The price of the wire stripping machine is relatively low, which is more economical than hiring multiple workers. At the same time, the wire stripping machine has a long service life and can be used for many years with proper maintenance.

Easy to operate

The use of the wire stripping machine does not require complicated adjustments, it is easy to operate, and you can quickly get started. And design and manufacture of the wire stripping machine take into account the user’s convenience, making the operation process smoother.

Strong adaptability

The wire stripping machine is highly adaptable and can handle wires of different types and specifications, almost meeting the needs of various specifications. Whether it is home wires, office cables or industrial wires, the wire stripping machine can process it.

Through the following video, you can see the entire process of how our wire stripping machine works more clearly.

Raw Materials & Applications

What Can we Process

what Industry Are We Suitable

The scrap copper wire stripping machine of BSGH Granulator can handle thick wires with different cable diameters, such as single core wire, multi-core wire, aluminum wire, sheet cable wire, armored cable, high voltage cable, optical cable, submarine cable, sheath flat wire, steel wire, etc.

The wire stripping machine can be widely used in wire production, electronic products, building electrical wiring, scrap cable recycling and other industries.

Maintenance Tips

Regular lubrication

According to the frequency of use of the copper wire stripper, apply an appropriate amount of lubricating oil or grease to the sliding parts and bearings regularly to maintain their flexibility and smooth operation.

Regularly check the blades

Regularly check whether the blades of the copper wire stripping machine are worn or damaged. If necessary, replace the blades in time to ensure the stripping effect and safety of the wire stripper.

Storage and preservation

When our copper wire stripping machine is not in use, it should be stored in a dry, ventilated place to avoid moisture or damage from external objects.

Safety precautions

When stripping wires, avoid using miscellaneous wires or scrap wires with plugs.

get free quote now!

As a leading scrap copper recycling machine production company, we are always committed to improving the quality of our machines in order to better meet your unique needs. Whether you require assistance with selecting the right machine for your operations or have inquiries about our specific machine, our professional team is here to support you every step of the way.

This form is totally secure so please don’t worry and send an email to tell us your copper cable stripping needs. We will reply to you within 2 hours.

copper scrap machine - Copper Granulators

The copper scrap granulating machine from our company represents an leading advanced technology for processing waste cables in the market. The operation begins with the main shredder, which crushes the waste cables into mixed particles of copper and plastic. Next, an air separator and a vibrating table work together to separate the mixed particles. This two-step separation process ensures the effective isolation of materials. The end result is pure copper particles and pure plastic particles.

Product Description

Model | Capacity | Weight(KG) | Power(KW) | Dimension(MM) |

BS-D75 | 70 KG/H | 1500 | 18 KW | L1700*W1600*H2200 |

BS-D10 | 100 KG/H | 1800 | 24 KW | L2230*W1600*H2000 |

BS-D30 | 300 KG/H | 3500 | 37.2 KW | L2700*W2100*H2300 |

BS-D65 | 500 KG/H | 4000 | 53 KW | L4200*W2250*H2850 |

ECO1000 | 700-1200 KG/H | 5800 | 76 KW | L7200xW7500xH2200 |

Hot Selling Copper Granulators of BSGH Granulator

Below are our company’s hot selling copper granulator machines, which have solid structure, highly reliable pure copper motor, and special alloy blades with good wear resistance. Using a copper rice machine can get 100% pure copper

-

Fully Automatic BS-D20 Scrap Wire Chopper Machine Factory 200KG/H

Read more -

Best Cost Performance BS-D60 Copper Wire Separator Machine in Selling

Read more -

BS-N125 Copper Recycling Machine with Electrostatic Separator for Scrap Cables

Read more -

400~700KG/H Hot Selling BS-N130 Cable Shredder Machine for Sale

Read more -

Large Capacity Industrial Copper Cable Granulators for Sale BS-F3000

Read more

Advantages of Copper Granulator Machine

Significant economic benefits

The copper resources in scrap wires and cables are of high value. You can use our copper granulators efficiently to recover the copper resources, thereby you can rely on them to obtain more money to live life.

Simple and efficient operation

The price of the wire stripping machine is relatively low, which is more economical than hiring multiple workers. At the same time, the wire stripping machine has a long service life and can be used for many years with proper maintenance.

Wide processing range

The copper granulators can process scrap copper wires of different specifications, and can also process mixed scrap cables of different diameters.

Excellent quality

BSGH Granulator manufactures its machines using high-quality materials and in compliance with the highest industry standards. We also test the quality of the machines many times during production, ensuring that each machine is of durability and longevity.

what parts of copper granulator machine you can assemble?

Copper granulator machines for scrap copper wire have small single machines or complete recycling lines. Small single machines have copper wire scrap stripping machines and single granulator machines; for a complete recycling line, we can choose to assemble different configurations according customer requests.

the must part

Crusher

Crusher is main parts, mainly for crushing copper wire scrap into mixed small copper rice and plastic granules for next step preparation.

air separator system

Aire separator system is crucial part for separating copper and plastic granules.

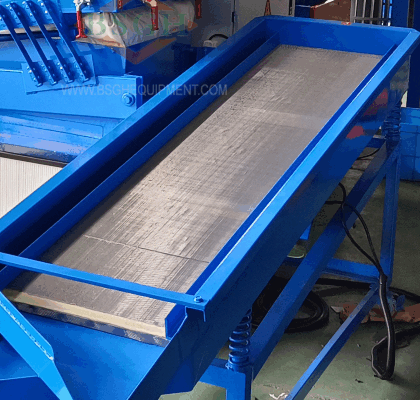

table vibrator

The small table vibrator machine have 2 kinds, one is for copper outlet and another one is for plastic outlet, they are not same.

optional configurations

Customers is able to choose different machine configurations according to which kinds of copper scrap wires they process; for different types of raw material, machines need to assemble different parts.

pre-shredder

Various shredder for options.

We have from small to big shredders for you to choose, from single motor 3KW shredders to big industrial 132KW*2 double motor shredders, welcome to consult our staffs.

electrostatic separator

If you have thin wires, hair wire such kinds very small wires, we recommend you assemble electrostatic separator for your granulator.

Double layer magnetic separator

A double-layer magnetic separator machine is configured after the copper outlet, the main function is mainly to absorb the small metals in copper granules.

Working Steps of copper granulators

First pre-shredder shreds cables into 5-25cm length.

By conveyor, crushed cables are conveyed to main crusher, which crushes them again into 3-5mm length plastic pieces and copper granules.

Mixture is sent to vibration system. By airflow gravity sorter and vibration screen, plastic pieces are separated from copper granules thoroughly.

Copper granules and plastic particles come out from different outlets.

Raw Materials & Applications

What Can we Process

what Industry Are We Suitable

Our copper granulators can process various cables, including household appliance wires, communication wires, computer wires, thick wires, automotive loom wires, etc.

Copper granulator machine is widely used in waste recycling stations, metal processing plants, automotive industry, cable manufacturers, etc. due to its high processing efficiency.

Maintenance Tips

The bearings of all running parts of our copper granulator machine have been filled with grease before leaving the factory, but this is limited to the debugging equipment. When officially using copper granulator machine, the bearings of all running parts should be re-filled with grease. Each running part should be filled with new grease every 40 hours of operation, and the crusher bearings should be filled with new grease every 8 hours of operation.

The blade will become blunt after a period of production, which will affect the crushing and sorting effects, so it needs to be polished every once in a while.

When polishing the blade, you should choose mechanical polishing. The blade will become narrower after repeated polishing. When the gap between the rotating blade and the fixed blade of the casing cannot meet the crushing requirements, the old blade needs to be replaced.

When polishing or replacing the blade, turn off the power before operating. Adjust the gap between the rotating blade and the fixed blade every time you polish or replace the blade.

get free Quote

Get the best copper wire granulator machine prices today. Our brand value is to let customers buy the most satisfactory machine at the most suitable price. Contact us today for a customized quote and get industry-leading copper wire granulator machines.

copper scrap machine | Recycle scrap Motors

By recycling and reusing the copper windings in scrap motors, the consumption of raw materials is reduced, the cost of producing new motors is reduced, and the pollution of waste to the environment is also reduced. The application and promotion of this technology is of great significance to promoting the circular economy and sustainable development.

Product Description

Model | Capacity(PCS/H) | Weight(KG) | Power(KW) | Dimension(MM) |

BSM-10 | 50-70 | 750 | 5.5KW | L2400*W1100*H1300 |

BSM-30 | 60-80 | 395 | 5.5 KW | L2310*W770*H950 |

BSM-40 | 0-120 | 670 | 7.5 KW | L1940*W1430*H1150 |

BSM-50 | 40-60 | 650 | 7.5 KW | L2140*W800*H730 |

BSM-60 | 80-120 | 508 | 4 KW | L1370*W1040*H1460 |

BSM-70 | 200-300 | 430 | 3 KW | L1500xW650xH800 |

Best electric motor stripping Machine

Below are our company’s high quality electric motor stripping machines, all of them have stable performance. You can directly click on the product link below to learn more about the specific details of the machine.

BSM-10 Motor Recycling Machine

BSM-30 Motor Recycling Machine

BSM-40 Motor Recycling Machine

BSM-50 Motor Recycling Machine

BSM-60 Motor Recycling Machine

BSM-70 Motor Recycling Machine

Advantages of Scrap Motor Recycling Machine

Hydraulic system

Our electric motor stripping machine is equipped with hydraulic cutting system and pulling system, which can easily cut the motor stator and pull out the motor copper windings. The copper windings can be pulled out all at once, which makes the machine’s processing efficiency higher.

High quality materials

The blades of most of our machine cutting parts are made of high manganese steel alloy with wear resistance, high hardness and good toughness, which can ensure a long service life and durability of machines.

Providing economic returns

The recycling cost of scrap motors is relatively low, and the market demand is very strong, so starting a business in this field can often obtain higher profit returns.

Easy operation

The motor recycling machine is very easy to operate and only requires one operator to complete the operation, which can greatly save your labor costs.

Working Steps of Scrap Motor stirpping Recycling Machine

Try to place one end of the motor copper winding under the cutting knife, then operator should turn around the motor manually after every cut until the copper winding is totally cut off.

Then put the stator on the copper pulling part to separate copper windings and silicon steel. Note: You should put the stator into appropriate

Raw Materials & Applications

What Can we Process

what Industry Are We Suitable

There are some raw materials can be processed by our motor recycling machine:

Motor recycling machines can be widely used in manufacturing enterprises, transportation enterprises, agricultural enterprises, motor recycling plants, etc.

Maintenance Tips

-

Tip 1

Before using the machine, check whether the electrical box has been flooded or damp.

-

Tip 2

Check the power socket and protective cover. If any damage occurs, please replace it in time.

-

Tip 3

There are two running tracks on both sides of the cutter, which need to be lubricated and maintained at least twice a day.

-

Tip 4

When the claws retract, there are several running tracks in the machine, and lubrication oil should be added for maintenance at least twice a day.

-

Tip 5

When the hydraulic oil tank is in use, add oil to 2/3 of the tank.

electric Motor stripping machine Price And ROI

Each machine is customized to your situation, so prices and ROI will vary.

Contact us for your exclusive quote。

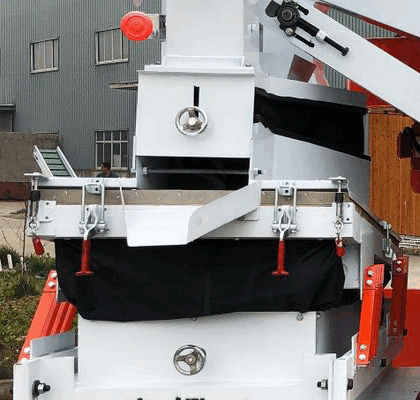

copper scrap machine | recycle scrap Radiators

Scrap radiators consist of aluminum foil and copper tubes, comes from scrap cars, water tanks and air conditioners, the main technical advantage of the radiator recycling machine lies in its processing capacity for scrap radiators. Our company mainly has two types of equipment for recycling radiators, namely radiator stripper machine and radiator recycling production line.

The radiator stripper machine is to separate copper tubes and aluminum foils in the scrap radiators, realizing the dual recovery of aluminum and copper. This machine has the characteristics of low investment and high efficiency. While, radiator recycling production line of our company divides three types: household appliance radiator crusher, water tank radiator recycling plant and car radiator recycling machine.

The main technical advantage of the radiator recycling machine lies in its processing capacity for scrap radiators. Through this equipment, aluminum and copper materials can be effectively recovered to achieve resource reuse, while reducing processing costs and improving resource utilization efficiency.

Advantages of Radiator recycling Machine

High cost performance

Radiator recycling machines of BSGH Granulator are very affordable, and can strip and separate all kinds of radiators, such as air conditioner radiators, car radiators, etc, for recycling copper and aluminum. You only need a small investment to get a huge return.

Wide processing range

The radiator recycling machine of BSGH Granulator can process a wide range of copper tube center distances. We can process radiator materials with center distances of 17.5mm, 19mm, 21mm, 22mm, and 25 mm. Of course, we also support customized services. If you have requirements for other sizes, you can contact us and we will customize them for you.

High efficiency

The radiator recycling machine of BSGH Granulator has a very powerful processing capacity, and the perfect blades structure makes the radiator stripper machine improves copper recycling efficiency essentially.

Easy operation

You only need to align the edge of the radiator with the thermovent, and then push the radiator into the feed port. The feed gear will firmly clamp the radiator and automatically complete the entire separation process.

Working Steps of Radiator Stripper Machine

Turn the Reversing Switch and check the rotating direction.

Inject oil into the two oil holes on the left and right side of the machine to lubricate transmission gears (usually once per 4 working hours).

Push different copper aluminum radiators into different Material Inlets according to their specs (19mm, 21mm, 25mm) for separating; the left side of radiators must touch the left side of Material Inlets; when radiators are pushed into Material Inlets, Feeding Gears will gnaw at radiators and take them into the machine.

After radiators are taken into the device, copper pipes and aluminum are separated and come out of the machine automatically.

According to the layers of radiators and their height, adjust each pair of Adjusting Wheels on the machine (after adjusting, tighten screws below).

Raw Materials & Applications

What Can we Process

what Industry Are We Suitable

Here are some radiator pictures to show you: flat and uncurved

Radiator stripper machine can be used in radiator recycling stations or factories, metal processing plants, construction industry, automobile radiator recycling, smelters, etc.

Notes before Working

Check if the power is connected well;

Check if the Guiding Rulers for each part is at the right position;

Check if the two Adjusting Wheels of each pair are on same level;

Start the machine and check if the machine is running at the right direction.

Contact Us

As a leading manufacturer who specializes in radiator stripping machine production, we always deliver top-quality solutions customized with your unique needs.

Whether require assistance about introduction for machines or have inquiries about raw materials, our professional team is here to support you with the greatest sincerity.

Your Reliable Scrap Copper Recycling Machine Manufacturer

BSGH Granulator is the best scrap copper recycling machine factory in China, we have been serving the copper recycling market fields for more than 25years.

Our company adheres to the concept of technological innovation, quality first, and honest management. It has a research and development team of senior engineers and management personnel, and is committed to creating world-famous brand products. The products of our company are sold at home and abroad, meeting the high-quality needs of European and American countries. In addition, the company also provides strong technical support and high-quality after-sales service, and providing high-quality products to customers across the country and around the world.

BSGH Granulator -Your most reliable partner

Your ultimate solution for efficient, eco-friendly copper scrap machine equipment – best scrap copper machine in China

Come and Enjoy an AR journey to BSGH ➜

Customer feedback

All the machines we sell support quality inspection because we have been verified by the market and recognized by relevant organizations, and customers are full of praise for our machines after using them.

what you can get from us?

The world keeps spinning. In this rapidly developing recycling market, we adhere to the spirit we pursue. Through this persistence, we have found our place and continued to develop. We believe that technology, innovation, integrity and mutual development are the directions we pursue.

Technology is the driving force for the survival and development of an enterprise. BSGH Granulator has its core technology and products. This determines our company's leading position and absolute advantage in market competition.

Innovation includes management innovation, technological innovation and service innovation. BSGH listens to customers' opinions with an open mind and improves its manufacturing technology and service awareness. We promote and strengthen ourselves in the process of development.

Integrity is the foundation of an enterprise. Only an honest enterprise can develop for a long time. BSGH Granulator attaches great importance to the spirit of integrity. We are looking forward to cooperating with you with full sincerity.

Our customers support us, and we repay them with high-quality products and thoughtful services. We are committed to achieving win-win results for our customers, employees, and the company.

Multi choice | One stop solutions

Contact US And We Will Help You Create Profit

We have professional technical team, service team to provide one-stop service from consulting, design, planning, manufacturing, installation for all kinds of scrap copper machines. If you have any needs, you could contact us directly.

Leave your doubts here to get what you care.