Leading motor stator and rotor recycling Line

- Our advanced system handles the entire recycling process of motor stator & rotor — from feeding scrap stators and rotors to crushing, sorting, and dust collection.

- With multi-stage sorting, it effectively separates iron, non-ferrous metals, and non-metallic substances, achieving high-quality metal recovery.

- As a leading manufacturer of motor stator and rotor recycling plant, we deliver reliable, large-scale solutions for maximum metal recovery.

- We provide the light model and heavy model according your material, capacity requests.

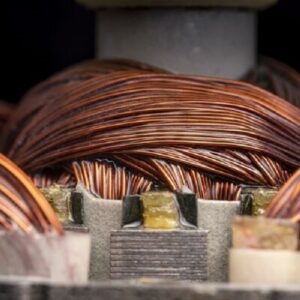

What is motor stator and rotor recycling line?

BSGH Granulator turns complex motor stator and rotor recycling into a simple, profitable, and safe process. Our fully automated motor stator and rotor recycling system is engineered to boost your bottom line and improve your profit to the best. Here’s what you can expect:

- Higher Profitability: Significantly lower your operating costs by eliminating expensive manual labor and maximizing the yield of high-purity copper and iron.

- Enhanced Safety: Create a safer workplace by automating hazardous tasks.

- Superior Efficiency: Our intelligent combination of crushing, magnetic, air, and eddy current separation ensures a continuous, high-volume workflow with exceptional material purity.

- A Smarter Investment: This is more than just a machine; it’s a sustainable, long-term solution for growing your recycling business.

Stop leaving money in your pocket. Discover how the BSGH Granulator machine can optimize your operation. Request a quote to learn more now.

High-efficiency motor stator and rotor recycling line for sale

We offer a variety of motor stator and rotor recycling plants designed to accommodate the processing capabilities of various recyclers. If you have unique types of motors or specific machine requirements, contact us and we’ll create a solution that perfectly suits your needs.

• Processing capacity: Up to 3000 kg/h

• Suitable for nearly all types of motor stators and rotors

• If your motor is still mounted on a housing, we recommend using a BSM-50 motor cutting machine to remove the housing before feeding.

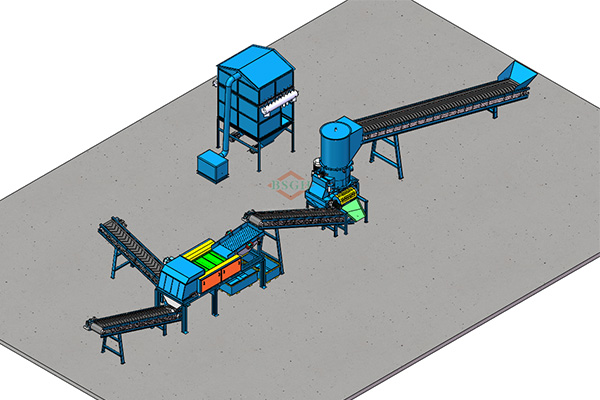

#900 Motor stator and rotor recycling line

Heavy-duty hammer mill + Vibrating screen + Séparateur magnétique + Electric control cabinet

#1200 Motor stator and rotor recycling line

Heavy-duty hammer mill + Vibrating screen + Magnetic separator +Pulse dust collector + Supporting dust removal pipe + Electric control cabinet

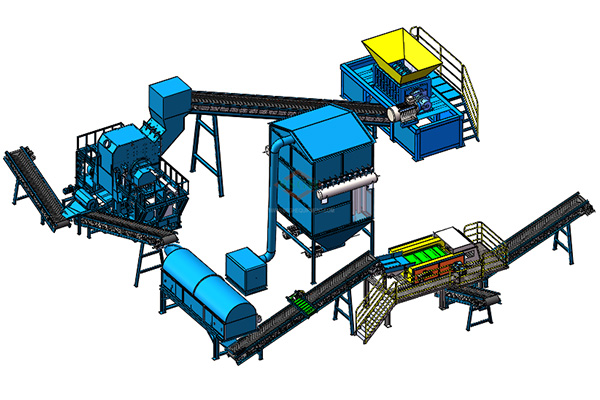

heavy duty Motor stator and rotor recycling line

Heavy-duty hammer mill + Vibrating bed + Magnetic separator + Vibrating screen + Winnowing + + Eddy current separator + Pulse dust removal + Electric control cabinet

Industrial Motor stator and rotor recycling line

Heavy-duty hammer mill + Vibrating bed + Magnetic separator + Vibrating screen + Winnowing + Belt magnetic separator + Eddy current separator + Pulse dust removal + Electric control cabinet

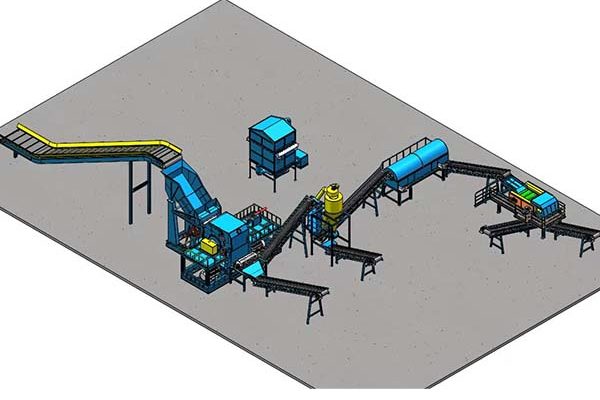

1-2T Motor stator and rotor recycling line

Heavy-duty hammer mill + Vibrating bed + Magnetic separator + Vibrating screen + Winnowing + + Eddy current separator + Granulateur de fil de cuivre + Pulse dust removal + Electric control cabinet

3T Motor stator and rotor recycling line

Heavy-duty hammer mill + Vibrating bed + Magnetic separator + Vibrating screen + Winnowing + + Eddy current separator + Copper wire granulator + Pulse dust removal + Electric control cabinet

Working steps of motor stator and rotor recycling line

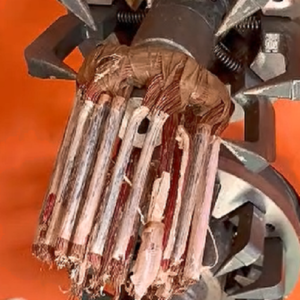

Step 1: Stators and rotors are evenly fed into the hammer-mill shredder by a feeding conveyor belt. Here, the materials are thoroughly crushed into particles through high-intensity impact.

Step 2: A magnetic separator extracts and separates the iron content from the crushed material, and ferrous metals are conveyed away via a discharge conveyor.

Step 3: The remaining mixed particles are transferred by conveyor into a vibrating screen. This step removes dust and fine impurities generated during the crushing process.

Step 4: The air separator applies controlled airflow to separate lighter impurities, such as plastics and rubber, from heavier metallic particles.

Step 5: A belt magnetic separator performs secondary removal of residual iron to guarantee complete ferrous separation.

Step 6: Finally, the treated material passes through an eddy current separator and granulateur de fil de cuivre (according to the model you bought). Using a high-frequency alternating magnetic field, it precisely separates valuable copper from non-metallic residues, ensuring a copper purity of up to 100%.

Check out above videos to see the high performance of our motor stator and rotor recycling line. It can efficiently separate ferrous, non-ferrous, and non-metallic materials from the stator and rotor in motors. If you would like to learn more about the machine details, please contact us!

Choisissez-nous, vous aide à obtenir deux fois plus de résultats avec la moitié des efforts

motor stator and rotor recycling line Key features and advantages

uniform feeding

Equipped with a conveyor belt to achieve uniform feeding. Prevent large pieces of materials from rushing into the crusher and causing overload, ensure the recycling system operates under a stable load, and guarantee smooth production.

Powerful shredding

The hammer mill rotates at a high speed, powerfully crushing the stator and rotor, so that the silicon steel sheets, shafts, bearings, copper, plastics, and insulating wood inside are fully separated and easily for the next sorting.

Fully Automatic Operation

The entire production line adopts an advanced PLC control system. Operators can use the buttons to start and stop, monitor the process, and adjust parameters, greatly reducing the difficulty of operation.

Over-Belt Magnetic Separator

Our permanent over-belt magnetic separator ensures a superior ferrous material purity and recovery rates, robust with no electrical magnets, leading to extremely low downtime and operating costs.

From Scrap stator and rotor to Profits

Our scrap motor stator and rotor recycling line is designed to transform complex waste into high-purity, valuable commodities. We turn the challenge of end-of-life motors into a profitable and streamlined opportunity.

Saisir: The process begins with a wide range of end-of-life motor stators and rotors, handling their varied sizes and compositions with ease.

Sortir: Through our advanced automated process, these mixed materials are precisely separated into distinct, high-value streams:

High-Purity Copper Particles: Ready for direct resale as a premium-grade metal.

Clean Iron Fragments: A high-quality feedstock for the steel and foundry industries.

Dense Non-Metal Blocks: Primarily containing silicon steel sheets, ideal for specialized recycling.

Lightweight Materials: Such as plastics, fiber and wood, were effectively removed for proper management.

Fournir une machine de haute qualité pour vous

Trusted motor stator and rotor recycling plant supplier

BSGH Granulator is a global leader in pioneering motor recycling technology. We specialize in delivering industry-leading, fully automated solutions for processing motor stators and rotors. Our systems are engineered to meet the specific demands of every client, from high-volume industrial recyclers to small and medium-sized enterprises seeking a fast and efficient return on investment.

The superior performance of our scrap motor stator and rotor recycling lines is extensively proven across European and North American markets. Recognized for their unmatched reliability, high output, and adherence to international environmental standards, our equipment has secured the long-term trust of a growing customer base.

When you choose BSGH Granulator, you gain more than just machinery; you secure a dedicated partner committed to driving your business growth. Discover the difference that proven technology and unwavering support can make.

What Our Clients Say

Our Motor Stator and Rotor Separation Lines are engineered for one purpose: to deliver unmatched profitability and efficiency to your motor recycling operation. They’ve experienced significant increases in metal recycling, reduced operational costs, and the robust reliability keeps their production running smoothly. Discover how our solutions are driving success across the globe.