Cisaille crocodile hydraulique

✓ Powerful shearing capability, maximum shearing force reaches 5000KN, easily shearing metal.

✓ Reliable and stable, always maintains excellent performance during high-intensity continuous work.

✓ We provide a full range of models from small to heavy hydraulic alligator shears.

Fabricant leader de cisailles crocodiles hydrauliques

La plupart des cisailles crocodiles hydrauliques adoptent principalement un système hydraulique car elles sont capables de couper tous les types de matériaux, de manière sûre et avec un couple élevé. Si vous souhaitez réduire la taille du matériau, ce type de cisaille est un bon choix pour vous, bon marché et facile à utiliser.

Pourquoi avons-nous besoin d’une cisaille crocodile hydraulique ?

Que peut faire la cisaille crocodile hydraulique BSGH ?

Le moteur électrique utilisé dans le système hydraulique de la machine BSGH est très puissant et entraînera le système hydraulique pour couper les objets et le matériau utilisé est très dur et résistant à l'usure, ce qui rend le processus de coupe fluide et facile.

L'ensemble du processus ne pollue pas, il n'y a donc pas lieu de s'inquiéter de la violation des politiques locales de protection de l'environnement et l'environnement dans lequel travaillent les opérateurs est également grandement amélioré. Ces machines sont sur le marché depuis de nombreuses années, ce qui a été prouvé par des clients du monde entier en matière de qualité et de durabilité. De plus, elles sont relativement faciles à entretenir, ce qui garantit une utilisation à long terme et une rentabilité.

High-quality hydraulic alligator shear for sale

Hydraulic alligator shear machine is ideal for reducing the size of materials. They are not only low in price, but also have high shearing pressure. Driven by a hydraulic system, they can easily shear various hard metal materials into small pieces. After shearing, the material is smaller in size, which not only simplifies the recycling method, but also makes transportation and storage more convenient and saves costs.

BSGH Granulator scrap metal cisaille crocodile hydraulique have stable performance, safety, and reliability, low failure rate, and low maintenance cost, and have been unanimously recognized in the scrap metal recycling market.

Types de cisailles crocodiles hydrauliques

Depending on the size of the processing capability, the thickness, and the hardness of the material, customers require products with different performances. We have various models of hydraulic alligator shears to meet all customers’ needs.

The main differences between the following products are oil pumps, oil tanks, and tonnage.

Plus la pompe à huile de la machine est grande, plus le débit est important. Plus le réservoir de carburant est grand, plus la machine dissipe rapidement la chaleur. Un tonnage plus important signifie une plus grande force de cisaillement et peut couper de l'acier plus épais.

But the blades of each machine are of high quality, wear-resistant, and durable, and are worth choosing.

| Machine | AS-60 | AS-250 | AS-630 | AS-1000 | AS-1200 | AS-1600 | AS-2000 | AS-2500 | AS-3150 | AS-4000 | AS-5000 |

| Force de cisaillement maximale (KN) | 60 | 250 | 630 | 1000 | 1200 | 1600 | 2000 | 2500 | 3150 | 4000 | 5000 |

| Force de pression maximale (KN) | / | / | / | 196 | 200 | 100 | 260 | 260 | 420 | 420 | 420 |

| Vitesse de cisaillement (fois/min) | 7-8 | 10-12 | 7-8 | 9-16 | 10-15 | 12-20 | 7-12 | 7-12 | 7-12 | 5 | 6-9 |

| Longueur de la lame (MM) | 300 | 300 | 600 | 600 | 600 | 700 | 800 | 1000 | 1200 | 800 | 1600 |

| Ouverture maximale de la lame (MM) | 160 | 160 | 280 | 335 | 300 | 320 | 380 | 480 | 520 | 700 | 886 |

| Puissance du moteur (KW) | 3 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 15 | 18.5 | 30 | 22 |

| Débit de la pompe à huile (ml/r) | 5.2 | 25 | 25 | 40 | 63 | 80 | 160 | 63 | 80 | 160 | 160 |

hydraulic alligator shearing machine usage

Les cisailles crocodiles peuvent couper de nombreux types de matériaux différents, tels que des objets aux formes spéciales tels que des cadres de vélo, des cadres en bois, etc.

The other is section steel, such as square tubes, round tubes, channel steel, and so on. It is widely used for cold shearing of round steel, square steel, angle steel, I-beams, plate steel, steel pipes, and other scrap materials, as well as for cutting fixed-length hot-rolled small steel, Steel rolling mill sections, cutting of scrap steel bars, small briquettes, steel plates, scrap cables and other heavy scrap materials in metallurgical furnaces.

Also, fit for plastic and wooden pallets, and many other light materials or heavy metals.

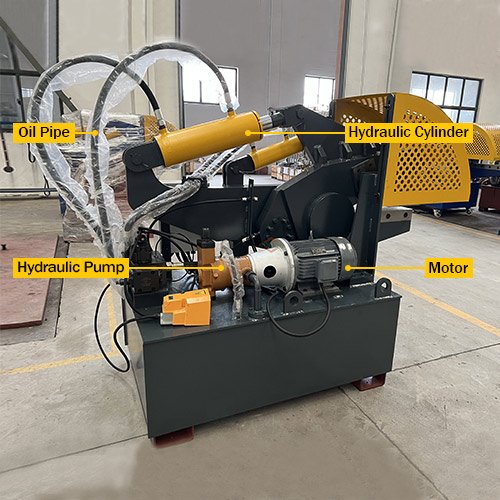

hydraulic alligator shear machine structure

La cisaille crocodile hydraulique BSGH Granulator a 2 types, l'un est de type intégré (principalement pour les petites pressions de cisaillement inférieures à 100 T), l'autre est de type divisé (principalement pour les grandes pressions supérieures à 100 T) ; toutes les cisailles sont principalement composées d'une partie mécanique, d'une partie électronique et d'une partie hydraulique.

- Partie mécanique : Elle se compose principalement d'un cadre, d'un support de lame et d'un vérin hydraulique, etc.

- Partie électronique : Il y a deux parties comprenant le circuit de commande du moteur et le circuit de séquence de mouvement.

- Partie hydraulique : La partie hydraulique est un ensemble composé d'une pompe, d'une boîte à vannes, d'un cylindre et d'une canalisation.

Les images suivantes montrent la structure détaillée de notre cisaille crocodile hydraulique AS-630.

La galerie d'images suivante présente les principaux composants des machines présentées dans les deux schémas structurels ci-dessus.

Comment fonctionne une cisaille hydraulique Alligator ?

En termes de principe de fonctionnement, notre cisaille crocodile hydraulique utilise la pression hydraulique fournie par une pompe hydraulique pour entraîner des vérins hydrauliques afin de générer une pression de levier. Après le pré-pressage et le verrouillage, l'opération de cisaillement est réalisée sous la pression de cisaillement du vérin de pression principal agissant sur la lame mobile et la lame fixe.

L’ensemble du processus peut être divisé en deux étapes.

Première étape : L'opérateur doit placer l'objet sur la plate-forme de coupe. Ensuite, la plaque de pression sera posée pour fixer l'objet et la lame le coupera.

Deuxième étape : Chaque fois que la lame effectue une coupe, l'opérateur doit l'avancer d'une certaine distance en fonction de la longueur que doit avoir la partie coupante.

Remarque : Différents modèles de cisailles crocodiles hydrauliques peuvent couper différents types et épaisseurs d'objets. Cisaille crocodile AS-1200 à titre d'exemple, les tailles des différents matériaux de cisaillement sont les suivantes :

- Canal en acier : 180*70*6MM

- Acier d'angle : 100*100MM

- Acier rond : Ø60MM

- Plaque d'acier : 200*200MM

- Acier carré : 45*45MM

alligator shear machine videos

Below are some videos of our various alligator shears in action. They can continuously shear scrap metal materials in an automatic mode. Whether a small home model or a heavy-duty industrial model, they can maintain high cutting efficiency and smooth operation, making them your best choice for size reduction. Some of our customer is very happy to share his operating video of AS-5000 Hydraulic Scrap metal alligator shear machine with us. From the video, we can see the hydraulic alligator shear cut the objects very smoothly.

Granulateur BSGH - Votre fournisseur le plus fiable

Nous fournissons des solutions de recyclage de cisailles crocodiles hydrauliques personnalisées, personnalisables en fonction de vos besoins industriels ou domestiques et des conditions de votre site, offrant la configuration d'équipement la plus adaptée à vos besoins. Bienvenue pour visiter notre usine !

Venez profiter d'un voyage AR à BSGH ➜

Pourquoi nous choisir?

Our machines have been constantly updated, their performance has been steadily improved and is more cost-effective than many machines on the market. Our hydraulic alligator shear machine has different types, besides integrated type and split types for each kinds also have different power and pressure for you to choose.

Vous êtes toujours inquiet du nombre trop important de modèles de machines parmi lesquels choisir ? Peu importe, notre personnel professionnel vous servira et élaborera le plan d'achat le plus adapté à vos besoins de traitement et à votre budget.

Nous fournissons également un service après-vente pour vous assurer de pouvoir l'utiliser correctement. Je crois que nous méritons votre choix.

obtenez un devis gratuit maintenant !

Nos experts en conseil en ligne vous apportent la tranquillité d'esprit nécessaire pour répondre à vos besoins complexes en matière de personnalisation. Découvrez comment nous pouvons vous aider à transformer vos déchets en trésors. Envoyez-nous un e-mail dès maintenant.

Ce formulaire vous permettra d'envoyer un email sécurisé à BSGH Granulator.