Widely used material handlers machine for sale

• Designed for handling and feeding a wide variety of materials.

• Material handler machine with industrial-grade durability, reinforced steel structure, and wear-resistant grab.

• Extra-long arm and 360-degree rotating work platform.

• Fixed chassis to ensure high stability and safety.

scrap Material handlers

Material handlers are essential workers who move the flow of materials within a workplace, often in manufacturing or warehousing settings. They are responsible for receiving, storing, distributing, and shipping goods, ensuring efficient operations and smooth production processes. They can handling including scrap steel, rebar, industrial waste, gravel, scrap cars, scrap metals and construction debris and so on. Designed to replace traditional conveyor systems, it requires only one operator to move large volumes of material, significantly reducing labor costs and improving productivity.

Granulateur BSGH material handlers has a strong loading capability, and the maximum effective operating radius can reach 15800mm. The large bucket capacity can grab many scraps at one time. Whether loading, unloading, or sorting, this equipment ensures fast, safe, and cost-effective operations. It is ideal equipment for scrap recycling yards, steel mills, ports, etc.

Main parts brand:

- Main control valve(Italy NEM)

- Anti-explosion valve(Italy NEM)

- Pilot oil source block(Italy NEM)

- Pilot operating system Italy NEM)

- Oil cylinder (China)

- Hydraulic motor(Japan KAWASAKI)

- Grab material(Hardox450)

- Boom&Arm material T690

- AC (TCL)

High-performance material handlers for sale

We offer a range of models, each designed with a different working radius to suit various operational needs. All models feature a compact structure, smooth transmission, flexible control, easy operation, reliable performance, and fast material handling. Additionally, we provide customization options to tailor the working radius based on your specific site requirements.

| Modèle | #8900 | #9800 | #11800 | #13800 | #15800 | |

| Working radius | 8900mm | 9800mm | 11800mm | 13800mm | 15800mm | |

| Working pressure | 25 Mpa | 21.5Mpa | 21.5Mpa | 21.5Mpa | 21.5Mpa | |

| Puissance du moteur | 37KW+3KW | 37KW*2+3KW | 37KW*2+3KW | 37KW*2+3KW | 37KW*2+3KW | |

| Grapper capacity/Weight | 0.3m³/1-2.3t | 0.4m³/1-2.8t | 0.4m³/1-2.8t | 0.4m³/1-2.8t | 1m³/1-2.3t | |

| Grapper height(mm) | 10000 | 10500mm | 13500mm | 14500mm | 15500mm | |

| Boom length(mm) | 5000 | 6500 | 7600 | 8200 | 9600 | |

| Swing speed | 4-6 R/Min | 4-6 R/Min | 4-6 R/Min | 4-6 R/Min | 4-6 R/Min | |

- From 70kg/h to 2T/H or customized

- 99.9% recycling rate

- Versatile processing range: small wire: telephone wire, mixed wire, car loom cables, hair wire; big armoured cables and etc.

Over the years, we have continuously updated and improved our scrap cable recycling line, which now serves clients across multiple industries worldwide with proven efficiency and reliability.

Material handlers can also feed raw materials to the baler machine. BSGH Granulator offers a variety of presses à balles métalliques with different models and pressure levels — from small to large — depending on the type and volume of material you need to bale

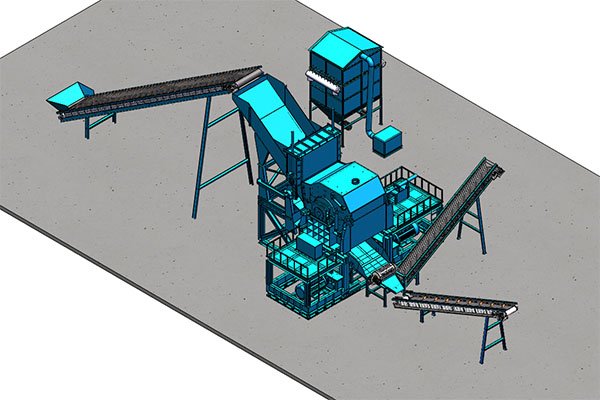

metal shredding line

find in the site

Advantages of our industrial material handlers equipment

Advantages of our industrial material handler equipment

haute efficacité

Our material handling equipment engineered for continuous scrap processing, our material handler machine maintains consistent 4-6 grabs per minute, ideal for high-volume material handling.

comfortable

The cab is equipped with air conditioning to ensure a comfortable working environment for the operator, even in the harshest conditions.

easy to operate

Unrestricted 360-degree continuous rotation allows precise gripping and positioning in crowded scrap yards. The smooth rotation lets you reach every corner, making even complex material handling feel effortless.

fiable

Driven by a hydraulic system, it provides smooth load control. There is no sudden vibration during operation, so you don’t need to worry about accidental drops or stalls when lifting heavy objects. It is safe and reliable.

long distance working

It adopts a reasonable structural design, straight arm + curved arm configuration. The straight arm can ensure a higher working range, while the curved arm can provide greater flexibility.

customer project case

See how our material handlers perform in real-world conditions in our customer site —working efficiently with other heavy duty equipment!

for our Singapore Customer

for our HK Customer