Machine de recyclage de compresseurs

BSGH Granulator offers a one-stop copper windings extracting machine for compressor scrap, superior in:

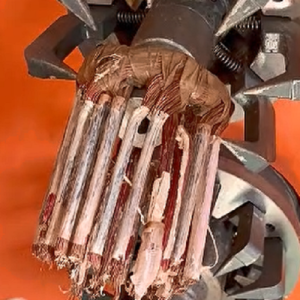

- Not only cut scrap compressor shell but also separate copper coil out with minimal copper loss.

- 100% precise cutting and safe pulling.

- Easy operation, one person can handle.

- Handle all scrap compressors such as round, flat, square, long or irregular shape.

- Invented by the recycling machine manufacturing leader with three decades experience and R&D team.

Why BSGH Granulator invents compressor recycling machine?

As is known scrap compressor is made up of hard steel case, valuable stator and useful rotor. The copper windings inside stator has a great value of recycling, but first you should break the tightly sealed shell, at this time, the compressor casing cutter machine can be put to good use. They are able to safely and precisely cut the tough shell, then you can pull the copper windings out with our stator recycling machine, thereby BSGH Granulator invents the one-stop compressor motor recycling machine, most driven by hydraulic system, keeping an intact copper windings extracting, boosting your profits, commonly used in scrapyard, recycling center from over 80 countries worldwide. If you have more needs, just feel free to contact us for specific needs.

As a supplier with all-sided models and most powerful machines de recyclage de moteurs in the world, Granulateur BSGH can provide you with efficient and economical compressor recycling solutions so as to lead the industry in such a fierce market competition, involving outer shell removal machine and inner stator copper windings separator machine.

We have two types of compressor casing cutting machines that can easily remove the tough steel case, ensuring a precise cutting to keep stator value, meanwhile, protecting your safety, thus, it has become a wise investment for motor recyclers.

Découpeur de carter de compresseur plasma abides by an advanced working principle: utilize an ultra-high temperature and high-speed plasma arc to melt and remove outer steel case, making it is a professional equipment favored by recyclers around the world.

- Vous pouvez vous adapter à des compresseurs de différentes spécifications en réglant la position de la tête du pistolet. Pendant le fonctionnement, la tête du pistolet s'ajuste automatiquement en fonction de la forme du matériau et s'arrête immédiatement une fois la coupe terminée, sans provoquer de gaspillage.

- Plasma cutter only takes an average of about 15s to complete a cutting process, which greatly shortens your processing time.

- Entire cutting occurs in a closed environment, effectively preventing operators from being injured, making sure a safety workshop.

- Capable of slicing both top and bottom just one pass.

- Cutting time: Single circle about 15″; Circle up and down about 50″.

- Able to handle different shapes of scrap compressors like round, flat, long, square or irregular shape.

Données techniques:

- Moteur: 13KW

- Longueur du compresseur : 150-550 mm

- Poids : 560 kg

- Diamètre extérieur du compresseur : 120-260 mm

BSCC blades compressor cutting recycling machine is equipped with 4 high-hardness blades and a rotating platform, suitable for standard round compressors. When running, the rotating platform drives the compressor to rotate at a constant speed, and then the 4 blades cut its outer shell.

- Adopts the mechanical structure, composed of cutting blades, a rotating platform, a control system, machine body and other parts, keeping blade compressor-cutting machine highly stable and easy to maintain.

- You can just press the button to control our blade cutter, easy to operate.

- Blades single circle cutting time: about 2-3 minutes(according different size of compressor, time will have little difference).

Données techniques :

- Moteur : 6,2 kW

- Longueur du compresseur : plus de 150 mm

- Poids : 820 kg

- Diamètre extérieur du compresseur : 120-260 mm

If you only have compressor motors, there is no doubt mini BSC stator cutting and pulling machine is your best choice, it is the cheapest motor recycling machine with 1 cutter and a 8-claw puller, only cost 2000USD and has enough ability to separate copper coils out and keep their value, ideal for your home use and scrapyard.

- Equipped with wheels, easy to move.

- Compact structure with 660 × 730 × 950 mm.

- Has control lever easy to adjust.

- Easy maintenance.

Données techniques :

- Moteur: 3KW

- Stator Diameter: Under 120MM

- Weight: 150KG

- Application: Small motors below 1.5KW

If you have other big scrap motors besides compressors, BSM-40 scrap motor recycling machine is an optimal one, hottest sale in BSGH Granulator, over 2000 sets are exported worldwide annual year, composed of 1 cutter + 3 puller, powerfully improving your high processing capacity in scrapyard and recycling center.

- Made up of one cutter, a 8-claw puller, a 16-claw puller in the front and a lifter at the back, the lifter can work together with each puller.

- Maximum stator diameter up to 500MM.

- Has 4 foot pedals to control, safe and easy to operate.

Données techniques :

- Motor: 7.5KW

- Stator Diameter: Under 500MM

- Poids : 670 kg

- Application: Can recycle all common scrap motors

Obtenez le meilleur prix aujourd'hui.

Notre entreprise s'engage à fournir des solutions de recyclage de compresseurs de haute qualité et des services à guichet unique. Nos machines de recyclage de compresseurs sont très reconnues par les clients étrangers, notamment au Royaume-Uni, en Pologne, en Malaisie, en Thaïlande, au Chili, etc. Vous pouvez obtenir les informations de prix les plus récentes et toutes les offres spéciales en nous contactant.

Étapes de recyclage du compresseur

Le recyclage des compresseurs usagés nécessite 3 étapes, vous pouvez suivre les instructions suivantes pour terminer le processus de recyclage du compresseur, facilement et avec une grande efficacité.

1. Placez le compresseur sur la plate-forme rotative du coupeur de boîtier de compresseur plasma ou de la machine de découpe de compresseur, démarrez la machine et la machine coupera automatiquement le boîtier du compresseur.

2. Après avoir retiré le boîtier du compresseur, placez le stator du compresseur dans la partie coupante de la machine de recyclage du stator du moteur et coupez une extrémité de l'enroulement en cuivre du stator.

3. Placez le stator du compresseur sur la partie de traction, utilisez la pédale pour contrôler les griffes pour serrer l'enroulement en cuivre et retirez-le.

Raw material and End Product

Compressor recycling machine is capable of cutting outer steel shell and pulling copper windings out from varying scraps, involving air conditioner (AC), refrigerator, and water tank, no matter round, flat, long or short even irregular shape, output with pure copper windings and two halves of casing.

Solutions fiables de recyclage de compresseurs de BSGH Granulator

BSGH Granulator professional R&D team is driven by innovation and inspired by customer demands, thereby engineering numerous machine options like cable wire stripping machine, machine à granuler les fils de cuivre, machine de recyclage de radiateurs, alligator shear, metal baler, briquetting press machine and diverse metal shredders, ensuring a wide adaptation to any application, including household, scrapyard, recycling center and waste management. In addition, each machine from BSGH Granulator is tested through a network of multiple processes from engineers in Department of Quality Assurance to enthusiastic users, guaranteeing a reliable machine performance. Last but not least, our considerate service gives you a comfortable purchasing experience, take compressor recycling machine as an example:

- Free-customized for you such as motor, logo, color, voltage and blades.

- 24/7 online service all over the sales process.

- Send the testing video for our client befor machine shipping.

- User manual is offered, meanwhile, technicians can also fly to your local place till machine is installed perfect.

- One year warranty.

- All machine has CE approval.

Plus de photos et de vidéos de machines de recyclage de compresseurs

vous pouvez vérifier ci-dessous

CE for Compressor recycling machine

FAQ

No. Both the plasma compressor case cutter and the compressor cutting machine are specially designed according to the characteristics of the compressor. If you need to remove ordinary motor casings, you can choose our Machine de découpe à moteur électrique BSM-50.

Oui, nous sommes disposés à vous aider à tester votre compresseur. En même temps, nous réaliserons une vidéo de test pour vous afin de garantir que notre machine a un effet de recyclage sur vos matières premières qui dépasse vos attentes.

Blades. Usually, we recommend customers buy some extra blades to meet long-term use needs.

The BSM-40 motor stator recycling machine can process almost all motors with a diameter of less than 500mm, such as refrigerator motors, washing machine motors, air conditioner motors, etc.

Oui, toutes les machines de granulation BSGH sont certifiées CE.

Dear friend, we know your concern and you only need to buy extra nozzles as spare use.

Do not worry, the spark will extinguish automatically upon contacting with air and very safe. Of course, before handling the compressor, you'd better remove the oil inside, if only a small amount, it's ok.