machine de recyclage de fils et câbles

Les machines de recyclage de fils et câbles sont les équipements professionnels les plus avancés du marché pour le recyclage des fils usagés. Ces machines sont capables de transformer une variété de tailles et de types différents de fils usagés en fils de cuivre entiers ou en particules de cuivre pur et propres. Elles varient en taille et en capacité, s'adressant à des opérations de recyclage allant des petites entreprises aux grandes installations industrielles. On peut dire que les machines de recyclage de fils et câbles sont essentielles dans l'industrie du recyclage en raison de leur construction solide, de leur fiabilité et de leur efficacité opérationnelle élevée. Puisqu'elles utilisent une technologie de séparation physique et sont équipées d'un équipement avancé de collecte de poussière par impulsion, ces machines respectueuses de l'environnement peuvent répondre aux normes mondiales de protection de l'environnement, vous aidant à utiliser nos machines de recyclage de fils et câbles dans le monde entier.

Nos machines de granulation de fil de cuivre

Les meilleures solutions de recyclage de fils et câbles

Granulateur BSGH est le premier fabricant de machines de recyclage de fils et câbles en Chine. Nous avons nos propres concepteurs professionnels et notre propre usine de fabrication de machines, et nous nous engageons à fournir des machines rentables à tous les clients. Nous fournissons principalement deux types de machines pour le recyclage des câbles usagés : les machines à dénuder automatiques et les machines à granuler le cuivre. Elles ont des domaines d'application et des groupes applicables différents, mais elles sont toutes deux une combinaison de hautes performances, de haute durabilité, de haute sécurité et de faible coût. Que vous appréciiez les performances, l'efficacité, la durabilité ou le prix de la machine, vous pouvez trouver une excellente solution chez BSGH Granulator.

Machine de granulation de cuivre

La machine de granulation de cuivre recycle principalement les câbles usagés par broyage et séparation. Tout d'abord, le broyeur broie les câbles usagés en particules mixtes de cuivre et de plastique de 3 à 5 mm. Ensuite, ces particules mixtes sont traitées par un séparateur d'air et une table vibrante et enfin séparées en particules de cuivre pur et en particules de plastique. Notre machine de granulation de cuivre adopte la technologie la plus avancée pour résoudre le problème de perte de cuivre élevée dans les machines de recyclage de fils de cuivre secs, avec un taux de récupération allant jusqu'à 99,9%.

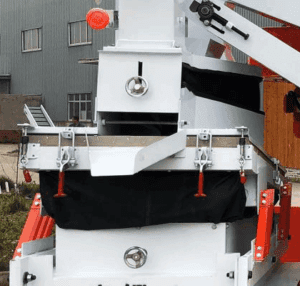

Structures de la machine à granuler le cuivre

La structure de la machine de granulation de cuivre est principalement composée de cinq parties : concasseur principal, séparateur de flux d'air, collecte de poussière, table vibrante, tapis roulant, etc. De plus, certains clients peuvent configurer pré-broyeur, séparateur magnétique, séparateur électrostatique ou d’autres dispositifs pour améliorer le taux de récupération en fonction de leurs propres besoins de production.

Fonctions des composants

Pré-broyeur

Déchiquetez les fils de ferraille en petits segments, les rendant plus adaptés au broyage ultérieur.

Broyeur

Il est responsable du broyage de petits segments en particules mixtes de cuivre et de plastique.

Collecte de poussière

Gérez la poussière générée pendant le processus de broyage des fils et améliorez la pureté du cuivre.

Tapis roulant

Transporter et convoyer des fils et des câbles usagés en vue de leur traitement et de leur manutention ultérieurs.

Table vibrante

Il comporte deux couches et son objectif principal est de réaliser une séparation efficace du cuivre et du plastique par vibration et criblage.

Séparateur de flux d'air

Séparez les granulés de cuivre et les granulés de plastique en fonction de leur différence de poids.

Séparateur magnétique

Absorbe le fer contenu dans les granulés de cuivre pendant le processus de production et réduit l'usure des lames de la machine de granulation de cuivre.

Séparateur électrostatique

Séparez les particules de cuivre et de plastique en profitant de la différence de conductivité entre le cuivre et le plastique.

Machine de granulation de cuivre série D

Machines de granulation de cuivre de la série D sont extrêmement rentables. Leurs prix de machine et leurs coûts d'exploitation sont bas, conçus pour vous aider à réaliser des bénéfices tout en minimisant vos coûts. Bien qu'ils aient une capacité de traitement plus petite, ils peuvent toujours traiter une large gamme de fils de ferraille et ont la même qualité élevée et les mêmes excellentes performances que les machines plus grandes. Nos machines de granulation de cuivre de la série D valent certainement bien plus que leur prix.

Machine de granulation de cuivre série N

Nous avons conçu notre Machines de granulation de cuivre de la série N avec efficacité et performance à l'esprit. Cette série de machines est principalement destinée aux clients disposant de grandes quantités de fils de rebut. Elles ont une capacité de traitement ultra-élevée, prennent en charge le traitement efficace des fils de rebut et peuvent maintenir des performances de travail stables pendant un fonctionnement à long terme. Si vous êtes intéressé par notre machine de granulation de cuivre de la série N, vous pouvez cliquer sur le lien pour en savoir plus sur les détails de la machine.

Désolé, nous n'avons trouvé aucun article. Veuillez essayer une autre recherche.

Les avantages de notre machine de granulation de cuivre

Haute efficacité

Notre machine de granulation de cuivre adopte une technologie de concassage et de séparation avancée et est équipée d'un système de contrôle automatisé pour réaliser un fonctionnement à un seul bouton, améliorant considérablement l'efficacité du recyclage et l'efficacité de la production.

Avantages économiques élevés

L'utilisation d'une machine de granulation de cuivre permet d'extraire les ressources en cuivre et en plastique des fils de ferraille. La pureté du cuivre et du plastique après extraction peut atteindre 100%, ce qui apporte des avantages économiques considérables à l'entreprise.

Large gamme d'applications

Nous disposons de nombreux modèles de machines de granulation de cuivre. Différents modèles ont des capacités de traitement et des diamètres de câbles traités différents pour répondre à vos divers besoins de production.

Faibles coûts

Nous utilisons une technologie avancée d'économie d'énergie pour réduire efficacement la consommation d'énergie des machines de granulation de cuivre, ce qui peut réduire les coûts d'exploitation et obtenir rapidement des bénéfices.

Machine à dénuder automatique

La machine à dénuder automatique est une sorte d'équipement mécanique de recyclage, qui est utilisé pour retirer efficacement et avec précision le matériau isolant extérieur des fils et câbles de rebut et récupérer le noyau métallique à l'intérieur.

Structures de la machine à dénuder

Notre machine à dénuder automatique comprenant principalement ajuster la poignée, trou d'entrée, lame, deux arbres de lame et deux rouleaux.

Fonctions des composants

Ajuster la poignée

Il comprend un dispositif de réglage de roue et un dispositif de réglage de lame. Le dispositif de réglage de roue ajuste l'écart entre les roues, le dispositif de réglage de lame ajuste l'écart entre les lames.

Trou d'entrée

Introduisez le câble dans le rouleau, de manière à entraîner le rouleau en rotation et à faire avancer le câble.

Lame

Les lames de la machine à dénuder les fils sont principalement utilisées pour dénuder et couper la couche isolante des fils.

Arbre de lame

Le contenu de l'accordéon d'images va ici ! Cliquez sur le bouton Modifier pour modifier ce texte.

Rouleau

Transport de fils et câbles usagés et d'extrémités de fils dénudées.

Série de décapage Machine de décapage automatique

Pour les machines de recyclage de fils et de câbles, une petite machine à dénuder les fils est le moyen le plus rapide et le plus adapté aux câbles qui conviennent à la machine à dénuder, le fil de cuivre dénudé peut également être vendu à un bon prix. Nous avons différents types de machines à dénuder les fils, des petites dénudeuses (adaptées aux diamètres de fil inférieurs à 72 mm) aux grandes machines à dénuder les fils (adaptées aux diamètres de fil supérieurs à 120 mm à 200 mm ou à une gamme de diamètres personnalisée), pour toute question, vous pouvez contacter notre personnel, notre personnel expérimenté vous donnera les meilleures solutions.

Les avantages de notre machine à dénuder

Améliorer l'efficacité et le rendement de la production

Notre machine à dénuder les fils peut fonctionner de manière entièrement automatisée, améliorant considérablement l'efficacité de la production et le rendement. Elle peut réaliser un grand nombre d'opérations de dénudage de fils en peu de temps, ce qui permet d'économiser efficacement les coûts de main-d'œuvre et de temps.

Garantir des profits économiques

Nos machines adoptent un système de coupe précis, qui peut dénuder avec précision la couche isolante du fil, garantissant la pureté du noyau métallique, garantissant ainsi de bons avantages économiques.

Versatilité

Nos machines à dénuder les fils peuvent être ajustées en fonction des différentes spécifications et exigences des fils, adaptées à divers types d'opérations de dénudage de fils. Cette polyvalence la rend hautement applicable et compétitive sur le marché.

Rapport coût-performance élevé

Le prix de notre machine est relativement bas, ce qui est plus économique que l'embauche de plusieurs travailleurs. En même temps, la machine à dénuder les fils a une longue durée de vie et peut être utilisée pendant de nombreuses années avec un entretien approprié.

obtenez votre meilleur prix aujourd'hui.

Vous pouvez comparer différents modèles de machines sur le site et prendre une décision. Si nécessaire, vous pouvez nous contacter et nous vous aiderons.

La différence entre une machine à granuler le cuivre et une machine à dénuder les fils

La machine de granulation de cuivre broie les fils et câbles de rebut en particules par broyage mécanique pour séparer le plastique et le cuivre. Elle convient au traitement de divers fils divers.

Tandis que la machine à dénuder les fils utilise une lame pour couper la couche isolante, recyclant ainsi le noyau métallique du fil, ce qui convient au dénudage des fils de diamètres plus épais.

Vous pouvez également cliquer sur le lien approprié pour obtenir plus d'informations sur leur différence

Granulateur de câbles et machine à dénuder les fils de cuivre, lequel vous convient le mieux ?

Ⅰ. Introduction Les câbles sont largement utilisés dans diverses applications partout où l'électricité existe. Par conséquent, d'énormes quantités de câbles usagés sont générées partout dans le monde.

Différence Nom | Machine de granulation de cuivre | Machine à dénuder les fils |

Principe de fonctionnement | Écraser le fil en granulés de cuivre et de plastique | Dénuder la couche isolante du fil |

Traitement des câbles de type | Fil réseau, fil de voiture, fil capillaire, fil de communication, etc. | Fil blindé, fil haute densité, fil multiconducteur, etc. |

Scénario d'application | Stations de recyclage des déchets, usines de traitement des métaux, industrie automobile, fabricants de câbles, etc. | Production de fils, produits électroniques, câblage électrique de bâtiment, recyclage de câbles de récupération, etc. |

Ce que nous faisons

Fabrication et approvisionnement

Nous sommes spécialisés dans la fabrication et la fourniture de machines de recyclage de fils et de câbles avec diverses capacités et fonctionnalités.

Nous nous concentrons sur l’intégration d’une technologie de pointe dans nos machines de recyclage de fils et de câbles pour améliorer leur efficacité et leurs performances.

Notre service client comprend l’installation, la formation opérationnelle et le support de maintenance pour nos machines de recyclage de fils et de câbles.

Pourquoi nous choisir?

Choisissez-nous pour notre expertise en matière de machines de recyclage de fils et de câbles, notre technologie fiable et notre engagement envers la satisfaction du client et le support technique.

Travail d'équipe efficace

La collaboration efficace de notre équipe améliore la productivité et l’innovation dans la fabrication de machines de recyclage de fils et de câbles.

Plus de 25 ans d'expérience

Avec 20 ans d'expertise, notre entreprise est spécialisée dans la fabrication de machines de recyclage de fils et câbles, offrant des solutions fiables et avancées.

Usine de haute technologie

Notre usine de haute technologie se concentre sur la production de machines de recyclage de fils et de câbles en utilisant des méthodes technologiques innovantes et des systèmes de production efficaces.

Plan de paiement flexible

Nos plans de paiement flexibles pour les machines de recyclage de fils et de câbles s'adaptent à différents budgets, garantissant des options de financement accessibles et gérables pour les clients.

Sourire client : Nous avons confiance que vous serez pareil avec notre client

Comment obtenir une machine de recyclage de fils et de câbles chez nous

Pour plus d'informations sur l'achat d'une machine de recyclage de fils et de câbles chez nous, veuillez contacter notre équipe commerciale, spécifier vos besoins et sélectionner une option de paiement appropriée.

01.

Enquête et consultation

Contactez-nous pour toute demande de renseignements sur nos produits, notre équipe vous propose des consultations d'experts pour répondre efficacement à vos besoins spécifiques.

02.

Personnalisation et Devis

Sur demande, vous recevrez des solutions personnalisées et un devis détaillé pour vos besoins spécifiques en machines de recyclage de fils et câbles.

03.

Confirmation de commande et fabrication

Nous commençons la fabrication précise après réception de la confirmation de la commande, garantissant une production dans les délais et le respect des normes de qualité spécifiées pour chaque unité.

04.

Livraison et support après-vente

Notre service de livraison assure un transport rapide et sécurisé des produits. Les machines bénéficient également d'un service après-vente complet pour le dépannage et la maintenance.

FAQ

Les machines de recyclage de câbles et fils en cuivre sont connues pour leur capacité à récupérer du cuivre à des niveaux de pureté très élevés, dépassant souvent 99%. Cette grande pureté est essentielle pour garantir que le cuivre recyclé répond aux normes de l'industrie et qu'il convient à une utilisation dans diverses applications, notamment le câblage électrique et la fabrication.

La capacité des machines de recyclage de câbles et fils en cuivre varie considérablement en fonction du modèle et de la conception. Nous pouvons vous fournir de 40 kg/h à 2 tonnes/h. Les machines plus petites peuvent traiter quelques centaines de kilogrammes par heure, adaptées aux opérations à petite échelle, tandis que les machines plus grandes et de qualité industrielle peuvent traiter plusieurs tonnes par heure, adaptées aux installations de recyclage plus grandes.

Le service après-vente comprend généralement une assistance à l'installation, une formation opérationnelle et des services de maintenance réguliers de BSGH Granulator. De plus, nous proposons généralement une assistance technique et un approvisionnement en pièces de rechange pour garantir la longévité et les performances constantes de la machine. Certains peuvent également proposer des services de dépannage et de réparation pour résoudre tout problème opérationnel qui survient.

Oui, les machines de recyclage de câbles et fils en cuivre sont conçues pour s'adapter à une large gamme de tailles et de types de fils. Elles peuvent traiter tout, des fils fins des appareils électroniques aux câbles électriques plus épais et isolés. Des réglages peuvent être effectués pour gérer efficacement différents diamètres de fils et types d'isolation.

La durée de vie varie en fonction de l'intensité d'utilisation et de l'entretien, mais en général, une machine bien entretenue peut durer plus de 10 ans. Un entretien régulier et le remplacement en temps voulu des pièces d'usure comme les lames et les grilles sont essentiels pour prolonger la durée de vie de la machine.

Parlons-nous de vos besoins en matière de granulateur

Faites-nous part de vos besoins spécifiques en matière de granulateur de fils. En fonction de vos besoins, nous développerons des solutions de traitement conçues pour améliorer l'efficacité et les performances de votre processus de recyclage.

- Whatsapp/Viber : 008613772508206

- Courriel : coppergranulator@bsghrecycling.com

- Site Web : https://bsghgranulator.com/