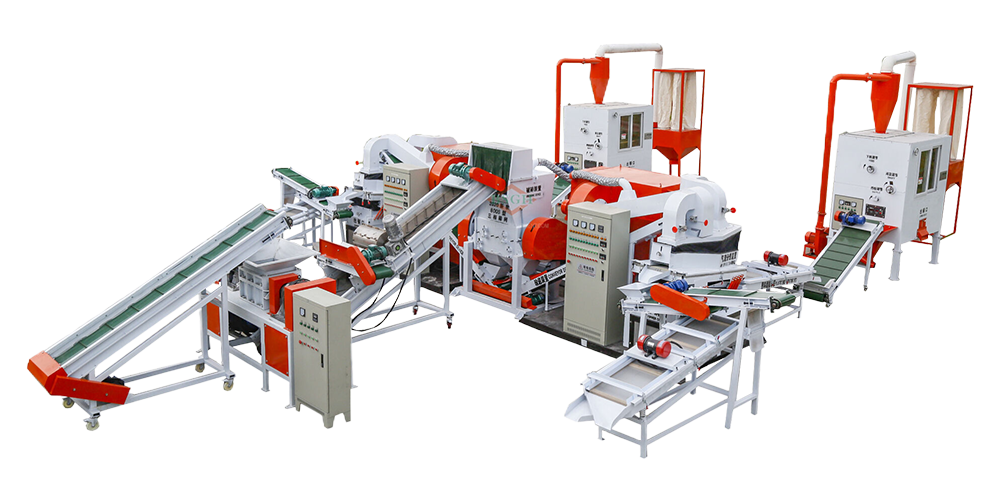

machine à granuler les fils

BSGH Granulator propose une large gamme d'équipements de granulation de fils à la fois efficaces et durables. Notre machine de granulation de fils peut traiter des câbles en cuivre et des câbles en aluminium. Elle est conçue pour répondre aux exigences strictes du secteur du recyclage des métaux, en convertissant efficacement les fils de rebut en précieux métaux de cuivre granulés. Notre machine est conçue pour un débit élevé, vous permettant de tirer le meilleur parti de vos efforts de recyclage tout en réduisant au minimum les temps d'arrêt. Nous garantissons la qualité et les performances de notre machine et fournissons une assistance pour garantir qu'elle répond à vos exigences opérationnelles. Avec notre granulateur de fils, vous investissez dans une solution fiable et performante qui répondra à vos exigences de recyclage pendant de nombreuses années.

Nos machines de granulation de fil de cuivre

modèles de machines à granuler les fils

Notre entreprise produit uniquement des appareils de granulation de fils de la plus haute qualité. Notre engagement constant envers l'excellence se reflète dans la planification et l'assemblage rigoureux de nos appareils, où seuls des composants de haute qualité et des technologies avancées sont utilisés. Pour garantir des performances et une durée de vie exceptionnelles, chaque pièce d'équipement est soumise à des tests complets et à des contrôles de qualité. Nous comprenons l'importance de la fiabilité dans les opérations de recyclage, c'est pourquoi nous nous consacrons à l'amélioration et à l'innovation continues. Nos clients peuvent compter sur nos machines pour offrir des résultats efficaces, fiables et de haute qualité dans leur traitement de récupération des métaux grâce à notre soutien et à notre expertise continus.

meilleur granulateur de câbles et fils électriques de BSGH Granulator

Que votre entreprise soit personnelle ou commerciale, petite ou grande, tout le monde veut la machine bon marché mais la meilleure qualité, mais vous en avez pour votre argent, tout le monde le sait, mais afin de répondre aux demandes du marché, nous avons finalement développé la série D de machines de granulation de fils de câble, ces machines sont robustes et aux performances parfaites, vous pouvez également selon vos demandes choisir les différentes configurations, ici vous pouvez obtenir les machines de granulation vraiment les meilleures et les plus rentables.

- Notre machine peut traiter des fils fins et épais d'un diamètre inférieur à 40 mm, car différentes configurations peuvent avoir une petite différence.

- Convient à tous les types de câbles, fils de voiture, fils téléphoniques, fils mixtes, matériaux spéciaux, câbles de télécommunication également les câbles de défi, etc.

Machine de granulation de fil pour fil de cuivre - CE

Toutes nos machines de granulation de fil passent les certificats CE, nous aidons également des tiers à inspecter pour les clients.

notre foire ifat et notre foire de canton

2 fois salons hors ligne IFAT et 2 fois salons hors ligne Foire de Canton. Les machines de granulation BSGH participent souvent aux salons du monde entier.

Obtenez le meilleur prix aujourd'hui.

Obtenez la meilleure offre sur notre machine de granulation de fil aujourd'hui et améliorez votre efficacité de recyclage. Notre équipement offre des opérations et une durabilité exceptionnelles, vous assurant de tirer le meilleur parti de votre investissement. Il s'agit d'un complément important pour toute entreprise de recyclage, car il est conçu pour un débit maximal et une récupération supérieure des métaux. Avec des prix abordables et une emphase sur la qualité, notre machine de granulation de fil est une option rentable qui ne sacrifie pas les performances. Investissez dans notre technologie dès aujourd'hui pour profiter des avantages d'une solution à faible coût qui produit des résultats cohérents et offre un retour sur investissement rapide dans le secteur concurrentiel du recyclage.

les avantages

Quelques points pour la machine à granuler les fils

Notre machine de granulation de fils présente plusieurs caractéristiques importantes, notamment une excellente efficacité de récupération des métaux, offrant le meilleur rendement à partir de divers types de fils. L'équipement est conçu pour un fonctionnement et une durabilité à long terme, avec des besoins de maintenance minimes. Il a un débit élevé, ce qui réduit le temps et les dépenses d'exploitation. Le granulateur produit des granulés de métaux précieux et propres, prêts à être revendus ou réutilisés. Il est simple à utiliser et polyvalent, et s'intègre parfaitement dans les processus de recyclage existants, ce qui en fait une excellente alternative pour augmenter les efforts de récupération des métaux.

Récupération efficace des métaux

La machine de granulation de fils excelle dans la séparation et la granulation des composants métalliques des fils, ce qui permet d'obtenir des taux de pureté et de récupération élevés de métaux importants tels que le cuivre.

Traitement polyvalent

La machine est conçue pour être adaptable, répondre à divers besoins de recyclage et améliorer l'efficacité opérationnelle globale. Elle peut traiter une large gamme de diamètres et de types de fils.

Durable et fiable

La machine de granulation de fil est conçue pour résister aux exigences d'un fonctionnement continu, garantissant une fiabilité à long terme et des performances constantes dans les applications de recyclage sévères.

Ce que nous faisons

Amélioration continue

Notre société se concentre sur l’amélioration de la conception et de la fonctionnalité de nos machines de granulation de fils pour garantir leur efficacité et leur efficience dans une gamme d’applications de recyclage.

Notre engagement fort envers l’excellence est visible dans chaque machine que nous fabriquons, car nous utilisons des matériaux robustes et une ingénierie précise pour garantir la fiabilité et la longévité.

Notre organisation offre une variété de services pour aider nos clients à optimiser leur investissement. Ces services comprennent la maintenance continue et les conseils opérationnels, ainsi qu'une assistance au processus de configuration initiale.

Pourquoi nous choisir?

Nos exigences en matière de machines de granulation de fils sont satisfaites par notre engagement constant envers l'excellence, la créativité et la satisfaction du client. Conçue pour une fiabilité et une efficacité exceptionnelles, notre machine est soutenue par un personnel engagé à fournir un service et une assistance exceptionnels pour garantir que les efforts de recyclage produisent les meilleurs résultats possibles.

Travail d'équipe efficace

Pour atteindre des objectifs communs de manière efficace et innovante, une coopération réussie allie différentes capacités, une communication ouverte et une attitude coopérative.

Plus de 25 ans d'expérience

Nous offrons une expertise spécifique dans les machines de granulation de fil, garantissant qualité, efficacité et innovation, avec plus de 25 ans d'expérience.

Usine de haute technologie

Notre usine utilise une technologie de pointe pour fabriquer des machines de granulation de fil de pointe, en mettant l'accent sur la précision, l'efficacité et les performances de premier ordre.

Plan de paiement flexible

Choisissez parmi une variété d'options de paiement adaptées à vos besoins financiers, garantissant un achat en douceur de notre machine de granulation de fil.

Comment obtenir une machine à granuler les fils chez nous

Contactez-nous directement pour discuter de vos besoins, recevoir un devis et passer une commande pour une machine de granulation de fil de haute qualité.

01.

Enquête et consultation

Renseignez-vous dès aujourd'hui et consultez nos experts au sujet de notre machine de granulation de fil pour améliorer votre processus de recyclage et votre rentabilité.

02.

Personnalisation et Devis

Pour un devis et des options adaptées aux besoins de votre machine de granulation de fil, veuillez nous contacter.

03.

Confirmation de commande et fabrication

La commande a été reçue et confirmée. Nous commençons actuellement la fabrication de votre machine à granuler les fils avec un niveau élevé de précision et d'attention.

04.

Livraison et support après-vente

Vous pouvez vous attendre à une livraison rapide et à une assistance après-vente dédiée pour garantir que votre machine de granulation de fil fonctionne correctement et efficacement pendant des années.

FAQ sur la machine à granuler les fils

Le broyeur de fils que nous fabriquons peut traiter une large gamme de fils, des fils de télécommunication fins aux lignes électriques à usage intensif. Il peut traiter à la fois les métaux ferreux et non ferreux, mais il fonctionne principalement avec le cuivre et l'aluminium. Pour une efficacité et une adaptabilité de traitement optimales, il est important de vérifier le diamètre exact des fils, le type d'isolation et la composition.

Pour séparer soigneusement le métal de l'isolant, la machine utilise à la fois des méthodes de vibration mécanique et de séparation par air. Des réglages et des modifications spécifiques sont disponibles pour différents types et tailles de fils. Cela garantit qu'il y a le moins de contamination possible et que le métal le plus propre et de la plus haute qualité est produit, prêt à être fondu et réutilisé.

Nos machines sont conçues pour consommer moins d'énergie. Elles utilisent la technologie la plus récente pour réduire la consommation d'électricité sans diminuer le rendement. Parmi celles-ci, on trouve des moteurs de taille adaptée, des variateurs de fréquence qui permettent de modifier la vitesse et des systèmes conçus pour produire moins de chaleur et perdre moins d'énergie.

Nous proposons un service d'assistance complet qui comprend un service sur site, un dépannage à distance et un large inventaire de pièces de rechange faciles à obtenir. Vous pouvez également parler à notre équipe d'experts de l'optimisation du fonctionnement, qui garantira que votre machine continue de fonctionner de manière optimale et dure le plus longtemps possible. Nous souhaitons établir des liens à long terme avec nos clients en étant toujours là pour eux et en les aidant.

Les granulateurs les plus rentables sont également disponibles avec différentes capacités et différentes configurations, à partir de 50 kg/h à 2 T/h, il s'agit de notre capacité de machine de granulation standard, nous prenons également en charge les granulateurs personnalisés de plus grande capacité, vous pouvez consulter notre personnel expert.

Parlons-nous de vos besoins en matière de granulateur

Veuillez nous indiquer exactement ce dont vous avez besoin pour une machine de granulation de fil. Nous élaborerons des plans de traitement personnalisés pour vous aider à recycler davantage et à gérer votre entreprise plus efficacement.

- Whatsapp/Viber : 008613772508206

- Courriel : coppergranulator@bsghrecycling.com

- Site Web : https://bsghgranulator.com/