Leading medium Copper Wire Recycling Machine Manufacturer

Onpage Catagories

Website Catagory

medium copper wire recycling machine at competitive price

Midium sized copper wire recycling machines, commonly referred to as copper wire granulators, are engineered to process scrap copper wires and cables by shredding them into small granules. These machines are designed to separate the copper from the plastic insulation, ensuring both materials can be efficiently reclaimed and recycled. A medium-sized copper wire recycling machine, with a processing capacity of 300 KG/H to 700 KG/H, provides an ideal balance of capacity and efficiency, making it perfect for mid-level recycling operations with high recovery rates.

We have more than 10 models of medium sized copper wire recycling machines, our machines are easy to operate just like our small granulator and big capacity granulators, our equipment is well-designed to increase copper recovery rates and help customers achieve high returns, and we have gained an excellent reputation both domestically and overseas.

We mainly have D series and N series copper wire recycling machines, the medium-sized copper wire recycling machine is mainly in the D series and fewer in the N series. The following is basic information about our medium-sized copper wire recycling machine:

- More than 10+ types of middle capacity machines for the corresponding market;

- Copper wire recycling machine price range from usd20000~usd100000+;

- With a capacity from 300KG/H ~ 700KG/H;

- D series copper wire recycling machines have the best cost performance.

customer Project videos

BSGH Granulator attaches great importance to our middle copper wire recycling machines quality assurance. We conduct thorough pre-shipment tests to ensure that your machine works flawlessly upon arrival. Although our machines focus on performance optimization during the design phase, the final test ensures that each component is in perfect working condition. This extra step minimizes risks that may arise when delivering your machine, giving you a worry-free experience. Below are the videos of middle sized copper wire recycling machines testing for our customers they are from all over the world, USA, Thailand, Chile, Mexico and etc. Through these videos, you can obviously see that our machine is very simple to operate and the purity of the processed copper is 100%.

Playlist

0:16

0:16

0:16

wide Application of medium Copper Wire Recycling Machine

Cable factory: If you are a cable manufacturer, our middle sized copper wire recycling machine will be your first choice for processing defective cables. It can help you recycle copper materials from defective cables, thereby saving production costs, not too big not too small for you.

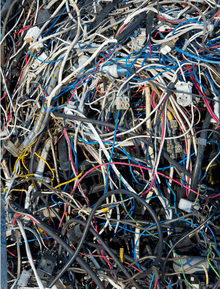

Wire recycling scrap yard:

If you work in the recycling scrap wires business, you can try our efficient and cost-effective middle copper wire recycling machine, our machine can help you process all kinds of your scrap cables. The purity of the copper processed by our machine can reach 100%, and the recycling value is high, so you can gain more profits; after you use our machine, it’s good for you to expand your business further.

Scrap metal yard: In the scrap metal yard, there are various scrap copper raw materials, such as scrap cables, scrap motors or scrap radiators; because of our medium copper wire recycling machine is multifunction so you can choose it to process cables and radiators in one machine.

Renovation and remodeling contractors: If you are a renovation and remodeling contractor with multiple projects, and you often accumulate many scrap wires in the process. Our machine can recycle these scrap wires for you to get pure copper materials, then you can sell copper directly to make more economic benefits.

No matter which fields are you in, if you have around 60T of scrap cables, our medium capacity copper wire recycling machines are the ideal choice for you.

Perfect Solutions for Processing Your Scrap Cables

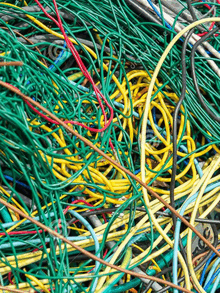

If handle any of the following materials, our medium copper wire recycling machine will process them perfectly and efficiently, helping you maximize recovery and get best value.

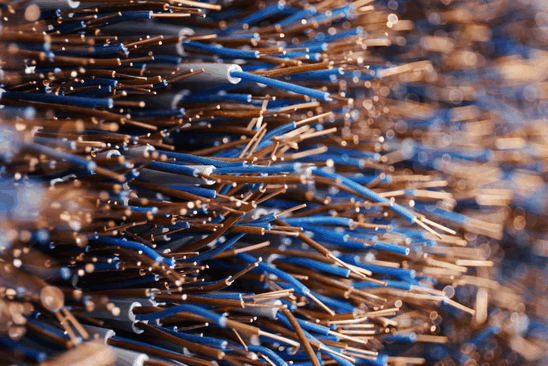

medium copper wire recycling machine raw materials

Normal cables: Medium copper wire recycling machine can process various types of regular waste cables, including household appliance wires, communication wires, computer wires, thick wires, car loom wires, etc.

Attention, please! Although the middle copper wire recycling machine can handle most of the waste cables, there are still some super thick wires that are not easy to handle. If you have a lot of these wires, we recommend collaborating with a wire stripping machine, which will save a lot of maintenance cost for you. The stripping machine will first remove insulation from thick wires, making processing easier and reducing maintenance costs.

For professional cable stripping machine, we always assemble with BSGHGranulator wire recycling machine together to serve our customer for better profit.

Special raw materiail:

Besides, we can adjust the machine’s inner components, making it suitable for processing unique materials such as scrap fuses, scrap mobile phone cases, waste radiators, etc.

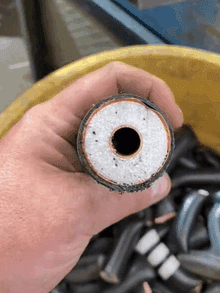

the end products with medium Copper Wire Recycling Machine

Plastic Granules

Copper Granules

about medium Copper Wire Recycling Machine structure

What components does the machine contain?

No matter big-capacity copper wire recycling machines or middle-capacity wire recycling machines or small, these granulators have some similar structures, just like all have crushers, air separation systems, small table vibrator bed and so on, but they are different in size.

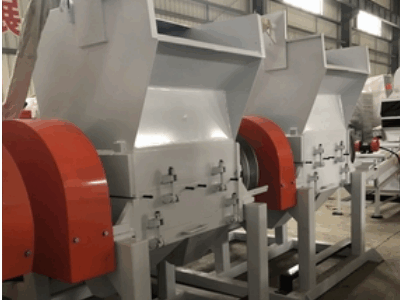

Crusher

The copper wire recycling machine’s crusher is a crucial component for recycling. It is used to crush wires for easier separation, the rotor has an alternating knife shaft, which boosts productivity, reduces noise, and improve stability during operation.

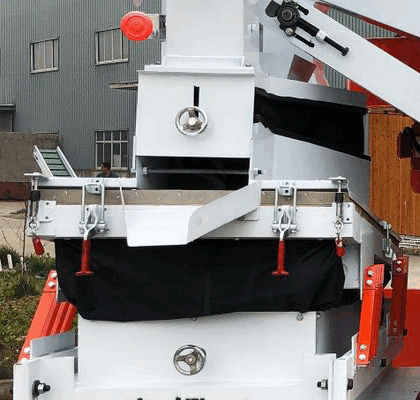

Air Separation System

No matter big or small or medium copper wire recycling machine, they are all have air separator systems, one or 2 or more.

Air separator system consist of the air bottom blow fan and air suction fan with air separation bed and the most important is the air separation sieve with various size for different kinds of wire recycling: 160mesh or 180 mesh or 200mesh.

Our air separation systesm have D series and N series also with A series, the principal and function are all same with similar structure; they are all can separate the copper from plastic very well.

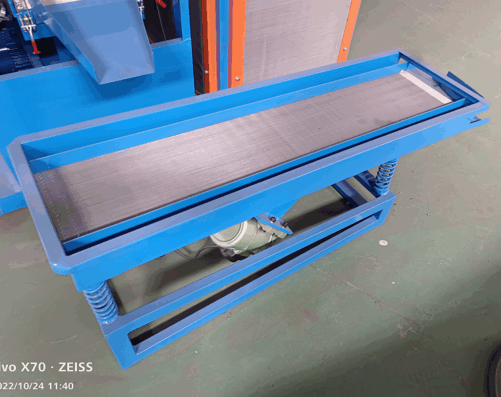

The Small Vibrating Separator

(for double separation purpose)

The small vibrating table machine for medium copper wire recycling originated in China. Its function is to achieve 100% separation of copper and plastic particles through secondary separation.

1. The small vibrating separator has two outlets, one for copper and the other for plastic, featuring an upper and lower double-layer structure. Its stainless steel screen has various-sized holes.

2. Larger copper particles cannot pass through the smaller holes and therefore are sorted to the top layer of the screen and discharged from the copper outlet; On the other hand, smaller copper particles can pass through the smaller holes and are sorted to the bottom layer of the screen.

Copper Outlet Small Vibrating Table

Plastic Outlet Vibration Separator

Double shaft shredder

(optional parts)

The double-shaft shredder is an optional accessory that you can choose to add or not. It is commonly used in conjunction with the scrap copper wire recycling machine to pre-shred waste cables and enhance the recycling process efficiency.

This machine operates on the principle of two shredding knife shafts rolling against each other to shear and shred materials. Different copper wire recycling machines are paired with different double-shaft shredders.

Magnetic Separation

Optional (for removing iron from copper)

Best medium Copper Wire Recycling Machine manufacturer

All BSGHGranulator machines are proudly made in China, offering exceptional quality and durability. We provide factory direct sale prices without any additional fees. Our medium copper wire recycling machines are continuously updated to keep up with global developments, so you can get higher sorting ability and increased output purity. These machines can process up to 700KG/H comparable to big granulators, but at a more affordable price.

BSGH Granulator - Your reliable partner in china

With more than 25 years of experience, we are the earliest manufacturer of copper recycling machines since 1995 in China.

Our machines are exported to 80+ countries and regions in the world.

We have established friendly and mutually beneficial cooperative relations with more than 100,000 customers.

Our market share in China has reached 70%~80%.

customer testimonial

BSGHGranulator has gained trust from all over the world for providing high-quality medium copper wire granulator machines and professional comprehensive service. We have received millions of positive feedback and praises, so there is no need to worry about our equipment.

What did customer say about our machine?

consult your copper recycling machine-BSGHGranulator experts

For any of your questions, we provide you best solutions, contact us freely!

For Big Medium or Small Granulators

6Tips help you use copper wire recycling machine smoothly

Before production, ensure the copper wire recycling machine’s power and frequency and that you can supply the appropriate voltage to run the machine. This will prevent safety hazards.

First, ensure that the machine is on flat ground.

Second, check if the wire connections are well-connected.

Third, check if all bolts are tightly fastened.

You‘d better familiar with the machine at first, control the feeding amount to about 50%–60% of the processing capacity of the machine, then gradually increase the feeding amount after continuous production for 3-5 hours, after you can skilled operation.

It’s better to control the wire diameter of each batch of raw materials to be consistent. Mixing thick wire and thin wires will affect the sorting effect.

After you finished the work every day, don’t turn off the machine immediately, this is very important, let the machine work for 2-3 minutes without load in order to let the crusher chamber empty.

The operator must stand on the side of the equipment when operating the copper wire recycling machine to prevent flying objects from attacking people.

Profit Analysis Of Scrap medium Copper wire Recycling Business

Here we just made analysis according to our machine BS-N125 copper wire recycling machine.

- Copper content we also make as 55%.

- Suitable for all kinds of cables.

- This method must be very helpful to new beginner and many customers.

- For this machine,normally one worker is enough.

| Running Cost/Day($) | ||||

|---|---|---|---|---|

| Input | Scrap Wires | Power Consumption | Workers | |

| Quantity | 4 Ton | 40.5KW/H*8H=324KW | 2 Workers | |

| Unit Price | 4691/T | 0.14 | 21.42/day | |

| Input Cost | 18764 | 45.36 | 42.84 | |

| Total Cost | 18852.2 | |||

| Income/Day($) | |||

|---|---|---|---|

| Output | Copper | Plastic | |

| Quantity | 4T*55%=2.2T | 1.8T | |

| Price | 10008/T | 300/T | |

| Income | 22017.6 | 540 | |

| Total Income | 22557.6 | ||

| Running Cost/Day($) | ||||

|---|---|---|---|---|

| Input | Scrap wires | Power Consumption | Workers | |

| Quantity | 4 Ton | 40.5KW/H*8H=324KW | 2 Workers | |

| Unit Price | 4691/ton | 0.14 | 21.42/day | |

| Input Cost | 18764 | 45.36 | 42.84 | |

| Total Cost | 18852.2 | |||

| Income/Day($) | |||

|---|---|---|---|

| Output | Copper | Plastic | |

| Quantity | 4T*55%=2.2T | 1.8T | |

| Price | 10008/T | 300/T | |

| Income | 22017.6 | 540 | |

| Total Income | 22557.6 | ||

Daily profit = Daily Income – Daily Cost= 22557.6 – 18852.2= 3705.4($)

We make the analysis according our customer’s data, for copper wire recycling business, must have great future, according to above format, you also can count your profits.

The FAQs About Medium Wire Recycling Machine

Customers maybe confused when buying a granulator machine, the following are some questions we prepared for middle capacity customers who often asked when buying a suitable granulator machine, hope it will help you!

Sure,our machine can process your plug cable.

If you have few plug cables,our machine can process well, no worry.

If you have large quantities plug cables, we professionally suggest to remove plugs first,that’s will be better to the blades.

Yes, of course. Our D-series and N-series machines can process car wire very well.

Notice: if your car wire has less tape, you can put it in the machine directly. But if have a lot of tapes, you need to add talcum powder.

I suggest you can check and sharp the crusher blades per 2 weeks, and use air gun to clean the air separation net and shaker table net regularly for best performance and high efficiency, all these maintenance very easy, will send you video link when you receive machine.

Yes, of course, we are professional, all of our machine have ce certification, and we also will put the CE mark on machine, when your machine shipped out, we will send the CE certification and all document to you.

It’s very easy. Welcome to contact our service department Whatsapp 86 18066799001 to get a video on how to do.

24 hours service available; We can customized according to customers' demands; Fast response for all clients' questions; OEM, ODM Service.

Our machine is dry type, only water tank needs to be filled with water to reduce main crusher blade temperature. And water is circulating.

Our machine electricity consumption is small, usually about 70% of machine power.

Dear friend, because our sa customer mentioned this kind document to me before, we have some knowledge of this, saber document is suitable for importing electrical appliances, our machine doesn’t belong that item machine, so you don’t need saber document when you import our machine.

Dear, when we got the machine working video already has our company logo, it is our company rule, sorry for that.

To be honest, We have many dealer consulted us, they usually buy 1 set machine first as a sample, then they can take more pictures and video put on website, local customer can also see the machine at your site, and if customer want to test the machine, he can take his wires to test, very convenient, many customer would like to buy a ready machine. Trust you know well.

All raw material we use is the best. About time of durability, i can’t tell you a specific time. It’s according to your use. When you feel machine process wire is not good, you can change the blade.( some customers sharp blade 2-3 month once time, some customer sharp blade 1-2 year)

Yes, we have. Our BS-D40 cable granulator machine can process PCB and cable wire very well. If you want know more, kindly contact Jocy Whatsapp 86 13772508206.

Machine capacity is tested many times by our technician, we sell this machine for more than 25 years, i can promise that all i said is true, you can rest assured. We also have a lot of good feedback from our customer, contact Jocy Whatsapp number 86 13772508206 know more.

Yes, we have. According to your needs, I recommend our BS-N130 multi-function granulating machine. Contact Jocy Whatsapp 86 18066799001 know more.

Yes, we are very weclome you become our dealer in your local. Conatct Jocy Whatsapp 86 13772508206 to talk more.