Radiator Stripping Machine Manufacturer

+ Wide application for all scrap radiators from air-conditioner (AC), refrigerator, car, water tank etc.

+ Suitable for single layer, double layer, 3layer, 4layer, 5layer or more layer radiators.

+ 100% separating rate + 100% purity for copper tube & aluminum foil.

+ CE approval + Patent number ZL201110259421.2.

+ Mature technology without after-sales issues.

+ 99.8% marketshare at least in China.

Features of the reliable radiator stripping machine

BSGH Granulator radiator stripping machine is specially designed with 2pairs of motors and reducer for efficient separation and recycling of copper tubes and aluminum foil from scrap radiators. It can directly process 1-2 layers of regular, flat and uncurved radiators. After processing you can get final pure aluminum foil and intact copper tubes for subsequent recycling processes or direct sale at a higher price:

- We support to customized different copper tube center distance for your various radiators: 32MM, 38MM, 40MM, 50MM or 60MM into one machine.

- The pressing plates are all heat-treated.

- Blades is HSS materials, best in the market.

- Every machine we assemble the optional grating for free, very safe.

- Compact structure, adopts 6-rollers design, low noise, high torque, and enhanced working efficiency.

- Three rows of adjusting rods, increasing the adaptability for diverse scrap radiators.

- One worker can operate well.

High-performance radiator Stripping Machine for sale

Inspired by our customers’ diverse needs, we’ve mainly designed 2 types of copper-aluminum separator machines. These two models can both separate copper pipes from aluminum foils efficiently. Our radiator stripping machine is the best in the world, we have the invention patent for this machine, our machine sells all over the world, have much difference with other imitation one. If the radiator stripper machine can’t meet your production requests, please refer to our machine de recyclage de radiateurs for your reference. Now let’s explore the difference between these two regular machines BS-1200P et BS-1200S as below:

- Power: 3KW+4KW+2 reducers.

- Voltage: 380V or custom for you, 50Hz or 60Hz.

- Copper tube center distance: Support customization and accept the biggest distance 50mm.

Consists of a frame, two motors, two reducers, a feeding part, a cutting part, a separating part, a transmission part and a feeding panel.

- Processing Capacity: 3T/8H

- Gear Motor: Normal

- Triangle Belt: A Type (1200mm); B Type (1200mm)

- Machine Size: 1800*900*1350MM

- Machine Weight: 600KG

- Feeding Inlet: 3 inlets

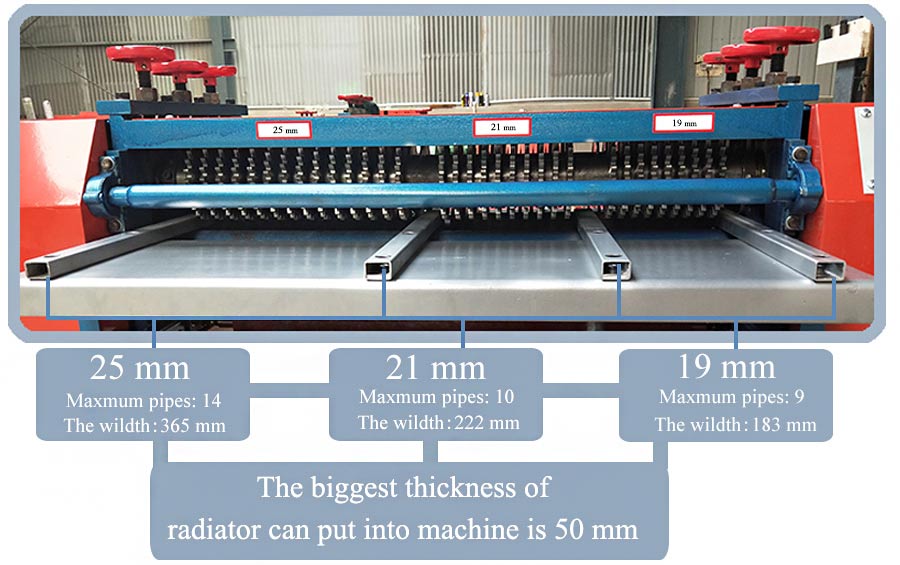

- Standard Copper Tube Center Distance: 19mm, 21mm, 25mm

- Processing Capacity: 4T/8H

- Gear Motor: Enlarged

- Triangle Belt: A Type (1300mm); B Type (1350mm)

- Machine Size: 2400*870*1150MM

- Machine Weight: 900KG

- Feeding Inlet: 5 inlets

- Copper Tube Center Distance: 17.5mm, 19mm, 21mm, 22mm, 25mm

Radiator stripping machine trouble-shooting

You may wonder how this superior radiator stripping machine work and if there is something wrong with it, how to solve it? Do not worry, let’s list one by one:

If radiators move towards left or right, check if the two adjusting wheels of each pair are on the same level.

When abnormal noise appears in working, check the working conditions of transmission gears, bearings and speed reducer as well as motors.

When radiators can not be cut from top to bottom, check if triangle belts are loose which causes slipping; or check if the blades become blunt.

After working for a period of time, speed reducer lubricant shall be replaced; check if screws become loose or not; check if blades and feeding gears become loose or not.

In practice, a single fault may have multiple reasons. We recommend first diagnose the root cause, then apply the appropriate corrections one by one.

radiator stripping machine working flow

The good machine must be able to let your entire process is fast and smooth, transforming scrap radiators into high-value resale treasure in just 10 seconds.

- Step 1: Turn on the switch and check the rotating direction first.

- Step 2: Inject oil on both side of the radiator stripping machine to lubricate gears once per 4 working hours).

- Step 3: Choose the suitable feeding inlet according to copper tube center distance, please pay attention to the left side of the upper layer of radiator copper tube must touch the left side of the inlets; or the right side of the upper layer of radiator copper tube must touch the right side of inlets, then feeding gears push them into the radiator recycling machine.

- Step 4: According to the radiator height, adjust(at the same time) each pair of roller handles to the proper position then tighten the screws.

- Step 5: After radiators are taken into the machine, copper pipes and aluminum will be separated and come out automatically.

raw material and Final product

The scrap radiator in the market is from different appliances:

- Most common of the radiator copper tube center distances in the market is 19mm, 21mm and 25mm.

- Also have others just like 75mm, 70mm, 65mm, 55mm, 50mm, 40mm, 38mm, 36mm, 34mm, for those kinds of radiators, the copper pipe diamter is 16MM, for these we ever produce for our customer.

No matter how many mm of your copper tube center distance is, our radiator stripping machine can turn your scrap radiators ranging from ac, fridge and water tank etc. into 100% clean copper pipe and aluminum foil, all can bring more profits for you, find out what they looks like:

Profit Analysis Of Scrap Radiator Business

Our radiator stripping machine is patented in separating your copper tube and aluminum foil with 100% separating and purity rate, boosting your profits, but what your really concern is the specific data for payback, let’s break down together:

Note: The data is real from the survey of our client, based on BS-1200P radiator stripping machine.

| Saisir | Scrap Radiators | Consommation d'énergie | Ouvriers |

| Quantité | 3T | 7KW/H*8H=56KW | 1 Labor |

| Prix | 3100USD/T | 0.14USD/KW | 21.42USD/8H |

| Coût d'entrée | 9300USD | 7.84USD | 21.42USD |

| Coût total | 9329.26USD | ||

| Sortir | Cuivre | Aluminium |

| Quantité | 1594.8KG | 1377.6KG |

| Prix | 8.37USD | 1.17USD |

| Revenu | 13348.48USD | 1611.79USD |

| Revenu total | 14960.27USD | |

Bénéfice quotidien = Daily Income – Daily Cost= 14960.27 – 9329.26= 5631.01USD

In a word, if you use our radiator stripping machine BS-1200P, will get payback within one day, please take our profit analysis form as a reference according to your local price. Hope you can also count your profit soon.

Choisissez-nous, vous aide à obtenir deux fois plus de résultats avec la moitié des efforts

Radiator Stripping Machine Unique Characteristic

Heat-Treated Compression Plate

The compression plate experience a strict heat treatment, making our radiator stripping machine more stable and durable so that this copper aluminum seprator performs better and serve a longer lifespan than other market models.

Optional Protection Guard

Every radiator recycling machine manufactured by BSGH Granulator has a standard configuration:

1: Light curtain, when your hands gets close to it, machine will stop working at once to protect your fingers!

2: Besides, the most frequently used part - feeding panel in an electroplated finish, enhances corrosion resistance more reliable.

Best partner with copper aluminum radiator stripping machine - band saw

If you need to process more than two layers or too wide old radiators, we strongly recommend buying a band saw together. You can first use it to cut the multi-layer radiator into 1-2 layers or cut the wide radiators into a suitable width, then feed it into the radiator stripping machine for separating.

- High cutting precision, without damaging the core copper and aluminum, ensuring its high recycling value.

- 3KW motor and 810M/Min rotating speed with sharp saw blade for fast and smooth cutting.

- Max processing width is 400MM & max processing thickness is 380MM.

- Easy to operate and stable performance.

- 380V voltage, single-phase needs to customize and extra fee.

- Low price, making it the best choice for pre-processing radiators.

Emballage et livraison

When your radiator stripping machines are ready, our factory carefully pack them in a strong plywood crate, assuring maximum protection during delivery. Afterwards, it will be safely shipped to your destination by sea. The whole process is absolutely seen in the pictures shown below, offering you a worry-free purchasing experience.

BSGH Granulator - leading inventor of radiator stripping machine

BSGH Granulator is not just an ordinary machine manufacturer, but the inventor of the radiator stripping machine, holding the unique patent No. ZL201110259421.2. As a pioneer manufacturer in the global recycling market, we stands out in:

- Our radiator recycling machine consistently leads the industry in structural design, stability, and lifespan. The optimized structure ensures 100% purity and 100% separate rate of the processed copper tubes and aluminum foil.

- The dual-motor + dual-reducer configuration guarantees strong power output, and name-brand components highly extend your machine’s lifespan.

- With proven global experience and leading technology, our radiator stripping machines have been exported to over 80 countries and regions, including Europe, the Americas, and Southeast Asia etc. Widely adopted by recycling enterprises of all scales, our system offer the most mature, stable, and field-proven radiator recycling solutions in the market.

- The copper aluminum separating machine has no after-sales issues, even no problem arises, our sincere support team provides prompt and effective online solutions to minimize your downtime and keep your business running smoothly.

Choose the Inventor. Choose Reliability. Choose BSGH.

Customized radiator stripping machine for customer

As is shown, our copper-aluminum radiator stripping machines standard configuration is: BS-1200P-3 Inlets with size 19, 21, 25mm; BS-1200S-5 Inlets with size 17.5, 19, 21, 22, 25mm. However, in practice, one size doesn’t fit all, so we offer customized feeding inlets tailored to your specific scrap radiators.

• Single, Large Inlet for bulky materials.

• Dual Inlets for processing two main sizes.

• Triple Inlets for handling a variety of sizes.

• Quad Inlets for maximum separation flexibility.

See these very less part of CUSTOM SOLUTIONS in action in the videos below, if more sizes needs for copper tube center distance, please freely contact us for specific information.

Liste de lecture

0:13

0:16

0:08

0:08

0:10

0:15

0:42

0:39

Our Chinese customer Gree customize a radiator stripping machine in 2023 with 21mm copper tube center distance with 1 inlet, totally boosting his profits.

In December, 2022, our Finland client purchased the customized BS-1200S radiator stripping machine with center distance of two copper tubes 21mm, 28mm, and 32mm.

Chile client only has one big size scrap radiator, so he purchase the copper aluminum recycling machine with one size for 19mm copper pipe center distance with 1 inlet, totally boost his profits.

In September, 2023, our Russian customer purchased the customized BS-1200P radiator recycling machine with center distance of two copper tubes: 17.5mm 21mm, 25mm, just ready in 7 days and on testing now, will ship to him soon.

Our Malta customer bought copper aluminum separator machine BS-1200S with blue color and distance between centerlines of two copper pipes 19mm, 22mm, 25mm and 30mm, 4inlet.

In December 2021, our Qatar client bought the BS-1200P radiator stripping machine with customized two feeding panels with 30mm copper pipe center distance, tested well and received with satisfying.

In May 2019, our Brazil client purchased one set radiator stripping machine with 2 sizes feeding panels for copper tube center distance 21mm and 19mm, totally making his profit boost.

In January 2023, Spainish client customize 2 feeding inlets with 32mm copper tube center distance for the radiator stripping machine, brings him higher returns.

CE for radiator stripping machine

ALL our radiator stripping machine passed CE certification, so you can rest assured to import.

FAQ

how many copper pipes can your BS-1200P radiator strippping machine process for each center distance?

When the radiator center distance is 25mm, it can process up to 14 copper pipes. The maximum width of the radiator it can handle is 365mm.

When the radiator center distance is 21mm, it can process up to 10 copper pipes. The maximum width of the radiator it can handle is 222mm.

When the radiator center distance is 19mm, it can process up to 9 copper pipes. The maximum width of the radiator it can handle is 183mm.

What voltage is required for the radiator stripping machine?

The standard radiator stripping machine voltage is 3phase and we also support voltage customization; but suggest three-phase voltage, single-phase is not recommended, if you want single phase we also can do for you, need to add extra usd1000 cost, for accurate price you can consult our sales.

How long can the radiator stripping machine run continuously?

The machine can work as long as you need, but it's better to take a break every 4 hours to cool down the machine, so that you can have a better working experience and extend the machine's lifespan.

Que dois-je faire si le cuivre et l'aluminium ne peuvent pas être complètement séparés par la machine à dénuder les radiateurs ?

Dear friends, it is because of the incorrect adjustment, but do not worry, there are three rows adjust handles, please just operate as follows:

- La première rangée de poignées sert à régler les dents d'entrée de la matière première.

- La deuxième rangée de poignées sert au réglage de la lame.

- The third row of handles is used to adjust the radiator outlet.

If have special situation, you can send us your video, then we will instruct you how to process.

Note: Please make sure that both left and right handles are adjusted simultaneously.

Is there any special maintenance required for the radiator stripper machine?

No, our radiator stripping machine don't need any special maintenance, only routine maintenance, such as cleaning and lubrication is recommended to ensure the machine's optimal performance. Detailed maintenance instructions are provided in the user manual.

How long should I change the blades of radiator stripping machine?

Generally, when processing the scrap radiator about 300T, you just need to change several blades according to blades' situation, suggest buying 25 extra blades as spare. And we also have blades changing video for your reference.

How to adjust the radiator stripping machine from 1 layer to 2 layers?

The radiator stripping machine has a push rod, when processing a single layer, push it to cover the blade below, and when processing a double layer, push it to expose the blades.

radiator stripping Machine customer case

Since you have reviewed our radiator stripper machine from the beginning until now, there is no doubt that our equipment — built with proven technology and superior quality — has earned widespread praise. In the following real customer cases, you’ll see how our copper aluminum separator machine makes more profits for global customers.