Small metal Briquette Machine

Small metal briquette machine from BSGH Granulator is worth for your investment, as it excels in:

- Capable of compressing different metal scraps — copper, aluminum, steel and cast iron chips into bales.

- Remove over 95% of cutting fluid, minimizes smelting losses.

- High-quality hydraulic cylinders can guarantee a leak-free operation for five years.

- Adopt a dual-rotation, three-in-one multi-directional screw feeding system.

- Equipped with Smart Human–Machine Interface (HMI) control system.

What is small metal briquette machine?

The small metal briquette machine is a compact hydraulic press that uses high pressure (typically ≤100 tons) to compress loose metal scraps into dense, solid briquettes. The simple, powerful forming technology directly solves three major challenges in metal recycling, making it an essential tool for modern scrap processing.

- Minimize Metal Loss

During smelting, fine and lightweight metal particles are easily burned or oxidized, leading to high material loss. By compressing these loose particles into solid briquettes, the small metal briquette machine greatly reduces melting losses and increases the metal recovery rate with low cost — ultimately boosting profitability. - Reduce Scrap Volume

Loose metal chips take up significant storage space and are expensive to transport. Briquetting machine transforms them into compact, high-density blocks that are easy to handle, store, and transport, helping reduce logistics costs and improve workshop efficiency. - Improve Recycling Value

Small, irregular or low-value metal scraps are often sold cheaply or discarded. By compressing them into dense briquettes, the mini metal briquette machine turns waste into valuable material, achieving full utilization of metal resources and contributing to sustainable recycling.

In summary, the small metal chip briquetting machine is ideal for compacting soft and ductile metal scraps. With simple structure, low cost, and reliable performance, it’s perfectly suited for small-scale or low-volume metal recycling factory or scrapyards.

Best-quality small metal briquette machine

Our small metal briquette machine has been continuously upgraded to deliver greater automation and efficiency in metal scrap recycling, specifically its superior lubrication and control system:

✅ Fully enclosed automatic lubrication system: Continuously lubricates all moving components to prevent metal chip buildup, ensuring smooth, uninterrupted performance even under heavy-duty, continuous operation.

✅Intelligent control system: Monitors the actual feeding capacity and controls the volume & weight of each cake.

high-performance Small Briquette Machine for sale

The BSGH Granulator small metal briquette machine is designed to transform loose metal chips and shavings from machining processes into solid, high-density briquettes. Compressing metal waste through high-pressure hydraulic forming, it significantly reduces chip volume, making storage, handling, and smelting more efficient. Although it’s small but it has same function with big hydrualic metal briquetting machine.

BM-60T Metal Briquetting Machine

- Power: 6.85KW

- Main Cyclinder Force: 60T

- Feeding Port Size: 450×550mm

- Max Pressure: 25Mpa

- Briquette Size: Φ70

BM-100T Metal Briquetting Machine

- Power: 15KW

- Main Cyclinder Force: 100T

- Feeding Port Size: 775×690mm

- Max Pressure: 25Mpa

- Briquette Size: Φ100

Structure & function of Small Briquette Machine

Our small metal chips briquetting machine is composed of three key parts — the equipment machine body, hydraulic system and electrical system. These three sections work in seamless to ensure excellent performance and reliable operation. The details of each component are shown below:

Consists of a compression chamber, a main hydraulic cylinder, a gate cylinder, a die, a punch, a punch rod, a feeding hopper, and a screw feeder.

The small metal briquette machine frame belongs to horizontal compression type, the front end of the main hydraulic cylinder is connected to the compression chamber via a flange. The mold sleeve is fixed inside its base, and the punch rod is connected with the top of the cylinder’s piston lever via hexagonal socket head caps. Both the die sleeve and the punch rod are removable and replaceable.

The screw feeder is driven by a gear motor. The transverse screw collects metal shavings from the hopper towards the center, while the longitudinal screw transfers the gathered chips to the compression chamber.

Consists of a motor, oil pump, combination valve, pressure gauge, level gauge, high-pressure hose, cooler, thermometer, air filter, and filter screen.

Hydraulic oil, after being pumped, enters the cylinder through pipelines and valve bodies, and the valve bodies control the reciprocating motion of the cylinders so that our small briquetting machine achieves actions such as squeezing, restoring, and feeding. Its pressure is adjusted by the relief valve on the side of the combination valve.

If oil temperature is too high (60℃), the small briquette press must stop working!

Consists of electronic components such as control switches, PLC, contactors, relays, overload protectors, pressure sensors, and temperature sensors. It operates stably within a pre-programmed sequence.

How does our small metal briquette machine work?

Here you can see the working process of our small hydraulic briquette machine. Our home use metal briquette machine operates through an advanced hydraulic system that automatically compresses loose metal chips into dense, solid briquettes. The process is simple, efficient, and fully automated — designed to save time, reduce waste, and increase recycling profitability.

Automatic Mode of Small Metal Briquetting Machine

Step 1: Retract the main cylinder and close the gate cylinder, then load metal chips into hopper.

Step 2: Choose automatic mode and the compact briquette machine will automatically feed chips into its compression chamber according to preset time.

Step 3: Once the chamber is fully filled, main cylinder begins pressing. After reaching preset pressure, the main cylinder retracts for one second.

Step 4: After gate opens, the main cylinder continues forward to push out the pressed block.

Step 5: Switch the control knob to Auto and press Start to begin fully automatic cycle.

Step 6: Before starting full automation operation, please first manually compress 3 to 5 briquettes to make the auxiliary oil tank at the top fill with hydraulic fluid.

Manual Mode of Small Metal Briquetting Machine

Step 1: Starting position: Main cylinder retracts to the bottom, gate cylinder closes.

Step 2: Screw feeding (low pressure).

Step 3: Main cylinder goes forward (compaction, high pressure).

Step 4: Main cylinder retracts for 1 second (release pressure).

Step 5: Gate opens (rising to the top).

Step 6: Main cylinder goes forward (expelling blocks, low pressure).

Step 7: Main cylinder returns (to the bottom).

Step 8: Gate closes (low pressure).

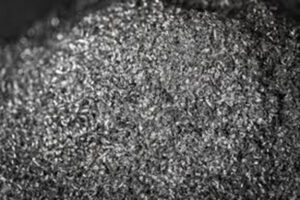

What can small metal briquette machine process & what can you get?

The BSGH Granulator small metal briquette machine is a compact and efficient solution — the ideal entry-level briquetting press for small to medium production volumes. Before processing, the raw materials are loose metal chips and shavings, such as copper, aluminum, steel, and cast iron. After compression, these materials are transformed into dense, high-quality metal briquettes that are easy to handle, store, and recycle. Let’s take a closer look at how metal chips briquettes looks like.

vous aurez une expérience agréable avec notre machine

Advantages of our small briquette machine

multi-directional Compression Feeding

The feeding inlet adopts twin-screw technology, the first screw scatters metal chips, while the second screw, designed with a three-way integrated structure, ensures a stable and continuous feeding.

Durable Feeding port

The inlet hopper is made of a manganese alloy plate + reinforced plate, increasing its strength meanwhile the low wear design makes our briquette machine resist impact and prevent deformation, serve for longer time.

Stable hydraulic station

With a thermal isolation and high-power cooling system, the oil temperature is precisely maintained within the optimal range, ensuring stable performance even under continuous heavy-duty operation.

superior cold pressing mold

The cold pressing mold is made of Switzerland high-strength alloy steel, offering exceptional wear resistance, low replacement frequency, and effectively reduces long-term operating costs.

high-quality cylinder

Highly customized hydraulic cylinder is manufactured as the aerospace-grade standard to ensure stability and reliability, guaranteeing no oil leaks for at least 5 years.

HMI system & touch screen

Equipped with an integrated HMI system and touch screen, our small briquette machine allows you to easily monitor key data in the entire operation, including running hours, output, and efficiency.

Fournir une machine de haute qualité pour vous

Choose small metal briquette machine from BSGH Granulator

BSGH Granulator takes a leading position in manufacturing robust and user-friendly machines with proven technology for versatile briquetting machines, absolutely shown in the small briquette machine.

- The robust structure specifically represents in its aerospace-grade standard hydraulic cylinder, the cold pressing mold made of high-strength alloy steel imported from Switzerland and manganese alloy plate + reinforced plate feeding port, all makes our small metal briquetting machine longer time use and more stable.

- The HMI PLC control system with touch screen makes the BSGH Granulator small metal briquette machine friendly to users, besides, each one is equipped with longitudinal and transverse reduction motor, strengthen the machine’s stability and easier operation.

Our R&D team is committed to engineering mature and innovative technology such as the newest dual-rotation, three-in-one multi-directional screw feeding system, making your waste fully recycled.

The superior after-sales service is essential such as customization support, 24 hours online response and one-year guarantee, whatever machine problem you meet, we are always here to solve for you.

All above promotes our machine’s superior performance, take the small briquette machine as an example, it can remove over 95% of cutting fluid, exceeding 97% market competitors.

In a word, our main goal is to maximize your satisfaction by providing the greatest recycling solution from our products and services.

Faults and solutions of small metal briquette machine

BSGH Granulator’s small metal chip briquette machine can serve for a longer time, while just like a person, there maybe something wrong and need to solve, the quick-reference guide below will help you swiftly diagnose and resolve common problems, ensuring a better use of our compact briquetting press;

| Problème | Possible Cause | Solution |

| No Operation / Machine Inoperative | Incorrect Pump Rotation | Check and reverse the motor direction. |

| Low Hydraulic Oil Level | Refill the hydraulic oil to the specified level. | |

| Stuck Relief Valve Spool | Dismantle and clean the relief valve. | |

| Solenoid Valve Failure | Inspect the electrical circuit and valve spool. | |

| Weak or Crumbly Briquettes | Low System Pressure | Adjust the relief valve setting. If unresolved, inspect and service the hydraulic pump. |

| Main Cylinder Internal Leakage | Replace the main cylinder seal kit. | |

| Low Voltage Supply | Check and correct the input voltage. Replace undersized wiring if necessary. | |

| High Sequence Valve Pressure | Adjust the preload on the sequence valve spring. | |

| Worn-Out Molding Die | Replace with a new die set. | |

| Hydraulic Cylinder Leak | Damaged Piston Seals | Replace the cylinder’s seal kit. |

| Incorrect Cycle Sequence | Improper PLC Timing Settings | Re-calibrate the action timing parameters in the control PLC. |

| Main Cylinder Won’t Retract | Loose Piston-Piston Rod Connection | Re-tighten the connection between the piston and piston rod. |

| Faulty Upper Limit Switch | Inspect, repair, or replace the upper limit switch. | |

| Stuck Fill Valve Spool | Service and clean the fill valve spool. | |

| Oil Leak from Main Cylinder | Damaged Piston or Scored Cylinder Bore | Replace the piston and guide set. The cylinder must be re-honed (recommended factory service). |

| Power Light On, Machine Won’t Start | Thermal Relay Tripped Open | Adjust the relay’s calibration setting and press the reset button. |

| Gate Cylinder Can’t Retract | Low Gate Cylinder Pressure | Increase the operating pressure for the gate cylinder and loosen the retraction stop screw on the base. |

| Briquettes Compact in Manual Mode but Not in Auto | The adjustment screw on the pressure relay has loosened | During automatic cycle, turn the adjustment screw clockwise until briquettes are properly compacted. |

This guide covers common issues only. In practice, a single fault may have multiple causes. We recommend a systematic approach: first diagnose the root cause, then apply the appropriate corrections one by one.

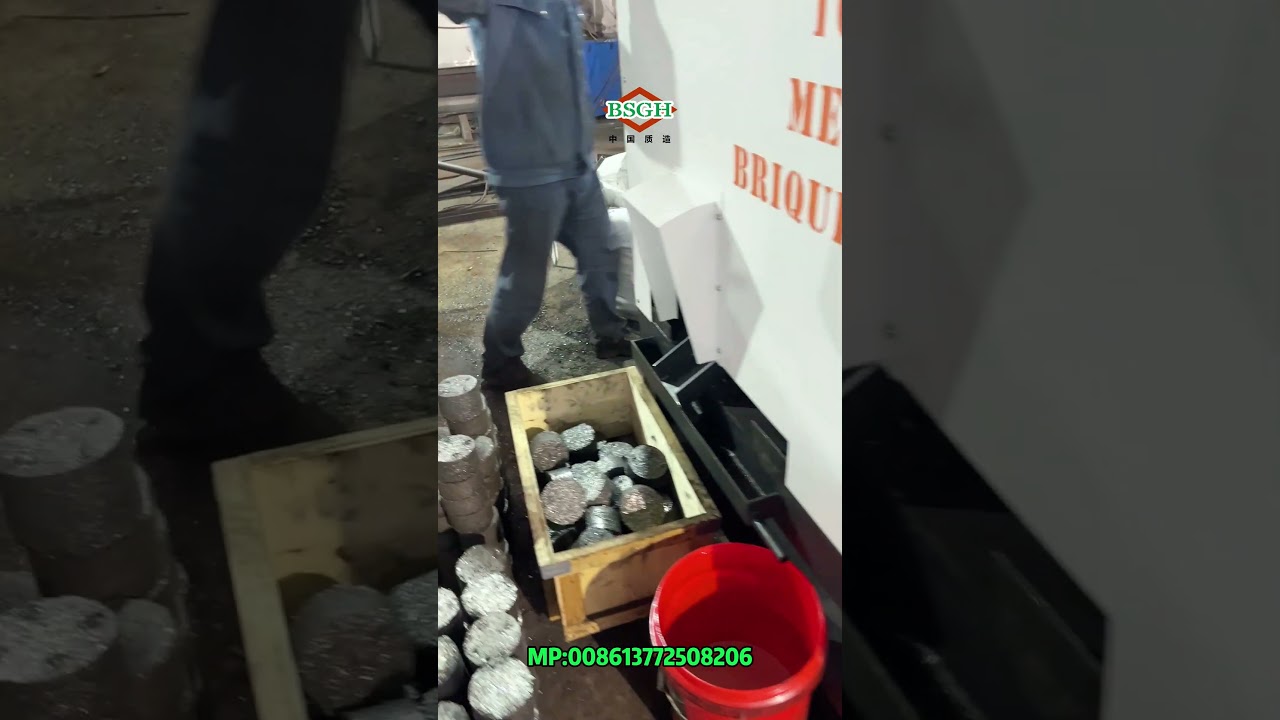

Working video of Small metal Briquette Machine

Witness our compact metal chips briquette machine in action from the video below. To see more detailed photos, specifications, or even a live demonstration, please do not hesitate to contact us. It’s our pleasure to provide you with more information as you need.

Liste de lecture

0:34

0:36

0:41

Customer Feedback on Small metal Briquette Machine

Customers love our small metal chips briquette machine for its reliability and performance. Discover why it’s trusted by so many — and contact us anytime to learn more!

FAQ

Will the pressed blocks from this small metal briquette machine fall apart during transportation?

No. The blocks pressed by our small briquette machines are high-density and have a solid structure, maintaining their shape and not easily falling apart during normal handling and transportation.

What's the price of your small metal briquette machine?

The price differs from 9500USD to 18000USD owing to various assemble, just contact us for optimal quote.

Is there any free spare parts for the small metal briquette machine?

Yes, our small metal briquette machine is assembled with

- Free hydraulic parts: 2 solenoid valves, 10 sets of pipe seals, 1 set of cylinder seals;

- Free electrical parts: 2 proximity switches, 2 relays;

Tools: 1 set (wrench, Allen wrenches, screwdrivers).

Does your small metal briquette machine support single phase power?

Yes, the small briquette machine default voltage is AC380V±10%/ 50HZ 4P, one phase needs to be customized, also you can contact us for specific requirements.

How to maintain my small briquette machine?

It is easy to maintain:

Please check that all wire connections are secure, especially the pressure relay, installed in a vibrating place and is easy to loose. If find any loosening, adjust it promptly.

The monitor is an LCD screen; do not scrub it with hard objects, as it may cause blurring and affect the display.