Wind Turbine Blades Shredder

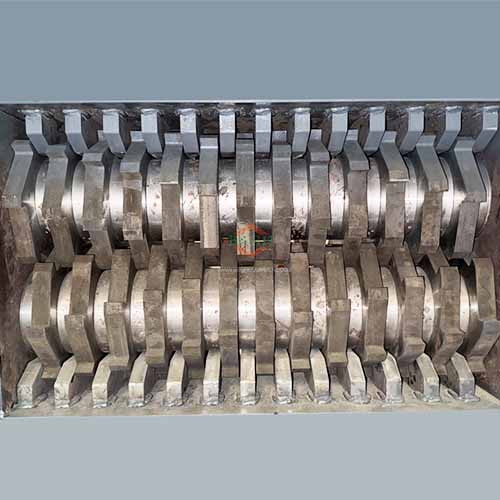

- Vertical blades shaft chamber

- Not only for shredding wind turbine blades also suitable for different big flat sheet materials, long pipes or tubes.

With unique and special dual-shaft crushing technology, the primary strength of our wind turbine blades shredder lies in its ability to process extra-long and uneasy cutting materials, efficiently making waste processing faster, easier, and more cost-effective.

How our wind turbine blades shredder Solve

Wind turbine blades are typically designed to last 20–25 years. However, once they reach end-of-life, disposal becomes a major challenge. These blades are made from durable composite materials such as fiberglass, resin, and reinforced plastics, which are extremely difficult to break down and recycle. Traditional recycling technologies often struggle to process wind turbine blades efficiently and safely. As a result, the recycling rate remains very low, while costs stay high. Many blades end up in landfills, where they occupy large amounts of space, or are sent for incineration, which can release harmful emissions. Both methods raise serious environmental and sustainability concerns.

BSGH Granulator wind turbine blade shredder is designed to effectively solve the challenges of blade recycling. With its vertical configuration, the machine makes feeding easier, reduces manual labor, and improves the tearing efficiency of composite materials. This design ensures safe operation while maximizing throughput and minimizing wear on the cutting system. It is a smart and cost-effective solution for processing long and oversized wind turbine blades into manageable pieces.

wind turbine blades shredder features

Notre wind turbine blades shredder is engineered to meet diverse industrial needs—ranging from waste acrylic PMMA Sheet materials to scrap wind turbine blades in wind farms.

Whether you are a manufacturer dealing with used materials, a wind farm operator managing huge blade retirement, or a recycling business major in composite material recovery, BSGH Granulator enables to offer a specialized model for your application.

Our shredders achieve high-volume reduction, smooth operation, and easier downstream handling—helping you turn recycling challenges into sustainable opportunities.

👉 Have specific recycling needs? Contact us today for a personalized crusher recommendation and expert support.

modular design

The crushing chamber adopts a modular design, allowing easier maintenance, inspection, and replacement of wear parts including lames, shafts, and bearings, greatly reducing downtime and shredder maintenance workload.

Protect Safety

Equipped with a PLC automatic control system, it has intelligent protection functions such as automatic overload reversal, effectively avoiding material jams and protecting core components.

front-feeding Structure

The front-feed structure makes operation easier and safer. Workers no longer need to lift heavy materials for feeding, saving time and effort while greatly improving feeding efficiency.

multifonctionnel

Each of our wind turbine blades shredder is multifunctional, not only can process wind turbine blades but also can process wide range of other scrap materials.

High cost-performance wind turbine blades shredder for sale

Granulateur BSGH offers a full range of vertical knife-box shredders engineered for the most demanding industrial recycling applications. Our shredders are available in different sizes to meet diverse processing needs. Whether you are shredding wind turbine blades, production scrap, or mixed industrial waste, our machines with serrated cutting blades deliver reliable performance with high efficiency and low maintenance requirements.

Designed to ensure maximum uptime and durability, BSGH shredders help reduce operating costs while providing a strong return on investment. This makes them an ideal choice for businesses looking for a cost-effective and sustainable solution in the recycling industry.

- Moteur : 75KW*2

- Blade: Φ500*60

- Axis: Φ230*6

- Size: 4500*2200*2400

- Moteur : 90KW*2

- Blade: Φ550*70

- Axis: Φ270*6

- Size: 5600*2300*2800

- Motor: 110KW*2

- Blade: Φ600*80

- Axis: Φ300*6

- Size: 6200*2530*2800

MS-D1800 wind turbine blades shredder

- Moteur : 132 kW*2

- Blade: Φ650*100

- Axis: Φ320*6

- Size: 6500*2530*2800

MS-D2000 wind turbine blades shredder

- Motor: 160KW*2

- Blade: Φ700*100

- Axis: Φ370*6

- Size: 7400*2800*3000

The wind turbine blades shredder machine is built to handle materials that are difficult to feed into traditional horizontal shredders. Its key advantage is processing long, flexible, and bulky items without pre-cutting, specifically stands out in handling:

- Plastiques Recycling: long plastic pipes, large plastic sheets, film rolls, and agricultural mulch films.

- Textile & Fiber Waste: carpet rolls, non-woven fabrics, and fabric waste.

- Paper & Cardboard: large rolls of packaging paper, cardboard cores, and oversized corrugated sheets.

- Domestic & Bulky Waste: MSW (Municipal Solid Waste) pre-shredding to break down large household items like furniture and mattresses.

- Light-Duty Métal Scrap: long, thin metallic waste such as aluminium profiles & light structural frames.

Due to special material of wind turbine blades, the powerful, low-speed shearing action of our side-feed shredder tears them into chunks ranging in size from 50 to 200 mm, specifically features in:

- Appearance: Irregular but relatively uniformly sized flakes or chunks.

- Composition: A mixture of glass fiber/carbon fiber, resin, metal, and core material convenient for subsequent efficient sorting.

MS-D1200 Wind Turbine Blades Shredder in action

This video showcases our MS-D1200 Wind Turbine Blades Shredder operating under real working conditions, efficiently processing wooden demo materials. The machine performs with outstanding stability—low vibration, minimal noise, and smooth continuous shredding without jamming or interruptions.

Engineered for durability and reliability, the MS-D1200 delivers consistent power and precision, making it ideal for handling challenging recycling tasks including composite materials like wind turbine blades. Its robust performance underlines our commitment to quality and customer satisfaction in industrial shredding solutions.

wind turbine blades shredder Customer Case

Customer:

A Spanish company specializing in recycling scrap wind turbine blades.

Problem:

- The blades were extremely bulky, making feeding difficult and labor-intensive.

- The toughness of glass fiber and resin often caused jamming.

Low shredding efficiency led to serious blade backlogs.

Solution:

MS-D1800 Wind Turbine Blades Shredder

Result:

The innovative dual-shaft system eliminated jamming, even for tough composites. As a result, production efficiency improved dramatically—backlogs were cleared, labor costs were reduced, and operations became smoother.

Customer Feedback:

“This machine has completely upgrated our recycling process. We can now deal with more blades in less time. The vertical feed design is excellent—it saves labor, runs smoothly, we have experienced zero jam and no downtime since installation.”

FAQ

How often should I replace the wind turbine shredder blades?

This depends on your usage. When the crushing effect becomes worse, you should replace the blades.

What if the machine gets stuck with extremely hard or unbreakable material?

Don't worry! Our machine is equipped with an intelligent PLC control system and an automatic overload reversal function. When encountering unbreakable material, the main shaft automatically reverses and removes the foreign object.

Besides wind turbine blades, can this machine handle other materials?

Absolutely. Our wind turbine blades shredder machine is versatile, heavy-duty shredder, also suitable for handling other scrap materials, such as scrap flat sheet materials, large plastic products and metal scrap.

How is your wind turbine blades shredder machine shipped? Where should I pick it up?

We usually ship the machine to your nearest port, and destination port agent will send you notification for arrivial, you can prepare documents and pick it up after making custom clearance after machine arrives at the port.