HDPE pipe shredder for sale

+ Advanced Shredder Machine Specialized for Crushing HDPE Pipes

+ Factory Direct Sales for HDPE Pipe Shredder

+Superior Quality Than Other Similar in The Market

what is HDPE pipe shredder machine?

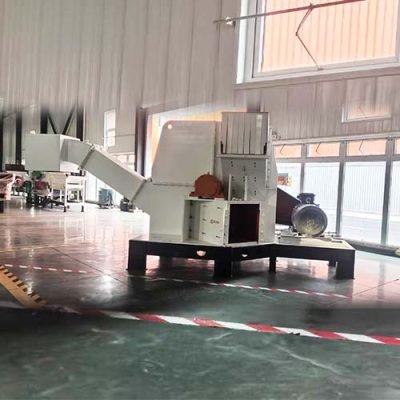

BSGH Granulator’s HDPE pipe shredder is a heavy-duty industrial machine designed to cut and shred high-density polyethylene pipes into small flakes for recycling. It can handle pipe diameters below 630mm directly and is commonly used in plastic recycling plants and waste processing facilities. If you have HDPE pipe diamter upto 630MM, you can use our HDPE Pipe cutting machine first and then process with HDPE pipe shredder machine.

Our HDPE pipe shredder stands out for its direct-feed design, high throughput, superior quality and long-lasting cutting blades, making it ideal for efficient and continuous operation.

HDPE pipe shredder selection

BSGH Granulator HDPE pipe crusher machine can process all kinds of big and small, thin and thick wall thickness diameter of HDPE pipes, offers a range of high-efficiency HDPE pipe shredders to meet different recycling needs and help customers maximize productivity.

#260 HDPE pipe shredder

Despite being the smallest model, #260 HDPE pipe shredder is hot sales with a 2-3T/H capacity—ideal for recyclers with a small number of HDPE pipes.

#420 HDPE pipe shredder

#420 HDPE pipe shredder, slightly larger than #260 model, handles up to 4T/H and is hot-selling in markets like Japan, France, and South America.

#520 HDPE pipe shredder

#520 HDPE pipe shredder is equipped with a more powerful 132kw motor, which can crush the raw materials into finer pieces.

#630 HDPE pipe crusher

#630 HDPE pipe shredder is the largest model, have a bigger crushing chamber, a powerful 185KW motor, and a capacity of 6–15T/H, perfect for large recycling stations and companies.

A multifunctional solution for HDPE plastic pipes

In addition to HDPE tubes, our pipe shredder can also easily handle almost all kinds of plastic tubes, including PVC tubes, ABS tubes, PE tubes, MPP tubes, PPR tubes, PP tubes, etc., and some plastic offcuts.

How does HDPE pipe shredder work?

The following are the working steps of BSGH Granulator HDPE pipe shredder for your reference. You can click the video on the right to see our machine shredding scrap plastic pipes efficiently and smoothly with stable performance.

STEP 1: After the machine is started, place the scrap HDPE pipes onto the conveyor belt. The feeding system delivers the pipes steadily and continuously to the shredding chamber, ensuring smooth operation.

STEP 2: As the rotor turns, it pulls the pipes into cutting chamber. This process is continuous and controlled to prevent overload and ensure safety.

STEP 3: Inside the chamber, multiple wear-resistant blades mounted on the rotor shred the pipes with consistent crushing force. The blade layout and cutting angles are optimized for handling thick-walled HDPE pipes with high efficiency.

STEP 4: Once the material reaches the target size, it passes through the screen mesh and is discharged through the outlet.

How to cut HDPE pipe with diameter of larger than 630mm?

HDPE pipe shredder can directly shred pipes with a diameter below 630mm without pretreatment.

So, how to process plastic pipes with larger diameters?

If you need to process pipes with a diameter larger than 630mm, you can use our pipe cutting machine to cut it into smaller pieces before feeding it into the pipe shredder. Here is a video of the pipe cutting machine in action for your reference.

HDPE pipe shredder Key features and advantages

Superior Shredding Performance

Blades are the core of pipe crusher, our blades are made from high-grade import steel and specially heat-treated for exceptional hardness, wear resistance, and strength. From small to large diameters, thin to thick-walled pipes, they deliver outstanding results across nearly all types of plastic pipes.

Two feeding inlets

(1)The upper inlet is mainly for manual operation to feed smaller or lightweight plastic pipes, offering greater flexibility and ease of use;

(2)The lower inlet usually works with a conveyor system for automatic feeding of large, heavy pipes—significantly improving efficiency and reducing manual labor.

Flexible Configuration choice

We can provide auxiliary equipment such as feeding conveyor belts and discharging conveyor belts according to your raw materials and capacity requirements, helping you achieve fully automated production and significantly reduce labor costs.

Frequency convertor start

Our HDPE pipe crusher machine adopts frequency convertor start, making the motor output smaller torque when starting and reducing impact. This can effectively save energy, reduce motor noise, and extend the service life our HDPE pipe shredder.

BSGH Granulator - Your reliable partner in china

As a leading HDPE pipe shredder manufacturer, we provide:

√ Cost-effective pipe crushers that perfectly balance excellent quality and reasonable price

√ One-to-one ordering assistance and after-sales service

√ Flexible personalized customization service based on your actual needs

√ Strict quality control, we will send you machine testing video before shipment

√ 12-month warranty

√ Lifetime 24-hour online quick response service

√ Professional installers can help you install the machine worldwide