Most advanced Radiator Recycling Machine for copper and aluminum separator

• Patented product invented by BSGH Granulator.

• With the most advanced separation technology, the final product metal purity is up to 99.9%.

• Multiple model options to handle different types of radiators and different efficiencies.

• Common radiators • Aluminum clad radiators • Heating Radiators

1st Generation(Current Market Machine), 2nd Generation, 3rd Generation

Best radiator recycling machine solutions

BSGH Granulator offers a complete range of radiator recycling solutions, covering almost every type of radiator on the market. Following five types of radiator recycling machines for your reference. You can choose according to your waste radiator type, or if you have special types of radiators you can contact us directly and we will recommend the most suitable machine based on your raw materials.

For our radiator recycling machine, we have radiator shredder recycling line and single radiator stripper machine, here you can find all types of radiators recycling solution in this page.

Radiator shredder Recycling Machine for Copper and Aluminum Separating Recycle Line

<2>This machine is suitable for all kinds of AC radiators, car radiators and water tank radiators, no matter it’s flat or curved or multi layers, you can input into machine directly, operation is very convenient; for most of the material no need to pre-process in advance.

<3>The most benefit is there’s very less copper aluminum clad, so save many of your labor force and cost.

How BS-ACP1000 radiator shredder machine works?

Our radiator shredder machine adopt the most advanced pre-shredder, which will reduce the copper aluminum clad than traditional plant, very less mixed materials. The best is you can process multi layer radiators directly, no need to pre-process. You can see the good performance from below videos:

- Customer: HK

- Bought: 2018

- Capacity: Process 20-30Tons per day

- Our customer have many scrap radiators per month, first he buy our first generation radiator recycling plant; after 3 years later, he bought our second generation machine, now use very well and machine in perfect condtion.

BS-ACP1000 Machine Advantages:

BS-ACP1000 radiator recycling machine is a kind of whole recycling plant, mainly used for separating copper, aluminum and iron in waste air conditioners and automobile radiators or water tank radiators. After the waste radiator is crushed by 2 smashes it will become copper and aluminum particles, after separated by aluminum separating machine and air separation system, the separation rate of copper, aluminum and iron can reach 99%. BS-ACP1000 capacity is about 2-3T/H, double the capacity of other normal radiator recycling machine in the market.

2: The ability to process various shapes of the radiator with no limit on radiator layers.

3: Fully automatic.

Equipped with a dust collection system reducing environmental pollution.

4: BS-ACP1000 radiator shredder recycling machine have 2 crusher.

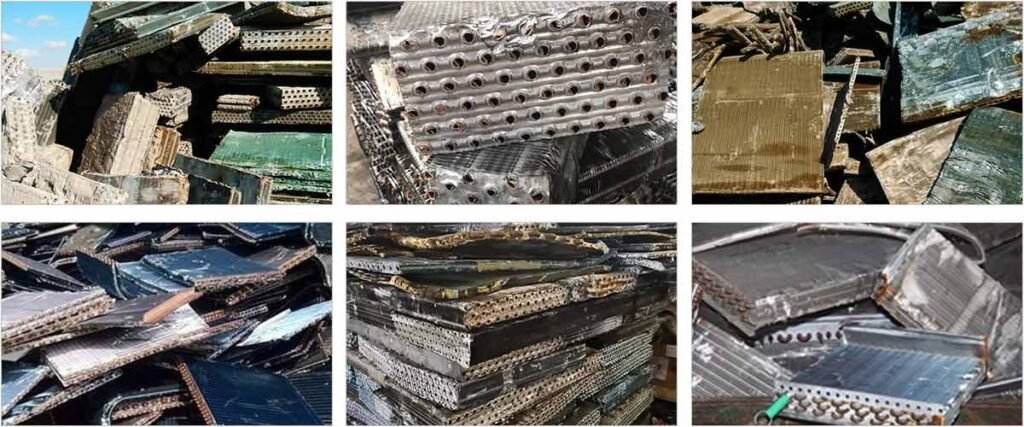

Raw Materials:

radiator shredder Machine technical datas:

| Model | BS-ACP1000 |

|---|---|

| Weight | 18000KG |

| Motor Power | 242.55KW |

| Capacity | 2~3T/H |

| Motor Voltage | 380V/440V/480V or Customized |

| Machine Size | 27000*8000*5000MM |

radiator recycling Machine Structure Show:

BS-ACP1000 radiator recycling plant is already updated to our 2nd generations, now our technical team also developed the 3rd generation and 4th generations, if you want to know more, pls contact our sales expert to learn more.

This radiator recycling plant includes the main parts besides a pre-shredder, fine crusher, 2 air separator beds, 2 magnetic separators and dust collection system, these parts are connect to each other and working together to complete the whole recycling process, following are the different parts for your reference:

- Crusher one: A special structure shredder which is different from a double-shaft is driven by a 110KW motor to crush the radiator into small pcs, the crushed mixed metal will not be twisted during the crushing.

- Crusher two: The fragmented radiator will be crushed into smaller Pieces in 5-25mm

- Pre-separator: Most of the lighter aluminum from metal mixture will be collected and other mixed metal will be conveyed to the vibrating table.

- Vibrating table: separate copper and remaining aluminum depending on their weight and air bottom fan.

- Magnetic separator: Iron will be separated through magnetic force and two separators are installed on the conveyor belt to make sure the Iron can be collected completely

- Dust collection system: to collect dust through suction fans.

Final Products:

The final products include both copper sheets and aluminum foils, with variations based on different machine configurations, with our machine you can get 99.9 copper recycled.

Small Radiator Recycling Machine

BS-1200S radiator stripper machine

• Same as BS-1200P radiator copper separator machine, it can directly process 1-2 layers of radiators.

• Suitable for copper tube center distances of 17.5mm, 19mm, 21mm, 22mm, and 25mm, also supports customization.

• BS-1200S radiator stripper machine has a processing capacity of about 4T/H.

BS-1200P radiator copper separator machine

• Can directly process 1-2 layer radiators.

• BS-1200P radiator recycling machine have 3 inlet.

• It can process waste radiators with copper tube center distances of 19mm, 21mm, and 25mm. If you have raw materials of other specifications, we can also customize them for you.

• Equipped with dual motors and dual reducers, low speed, and high torque, it can easily separate copper tubes and aluminum foil.

end products of radiator stripping machine

aluminum clad radiator stripper machine

BS-ACS20 radiator aluminum clad iron stripping machine

• It can process aluminum-clad iron radiators with inner diameters of 20mm, 22mm, 25mm, and 27mm, if you have other size, please let us know, we will custom for you.

• Sturdy construction, low maintenance.

• Suitable for iron tube or steel tubes, not fit for copper tube.

Heating Unit Radiator Stripper Machine

Heating Unit Radiator Stripper Machine

• The sharp blades can quickly cut the radiator shell and separate the metal tube inside.

• Best selling in cold areas.

• Suitable for iron tube or steel tube, not fit for copper tube.

Working videos of radiator recycling machines

Shipment:

Customer from all over the world:

One of our customers from HK, he buys our machine many years ago from the first generation, after he earned back his machine cost in 15 days; in 2020, he bought another set of our BS-ACP1000 for 2nd generation, already used so many years, from the small workshop to big recycling factory, we tks so much for our customer’s trust.

why Us?

With over 25 years in the copper recycling industry, BSGH Granulator is a trustworthy copper recycling machine manufacturer with more than 70% market share in China. Our radiator recycling machine features advanced technology for efficient separation and higher recovery rates with patent, maximizing metal resource value, occupy 97% market share in China. we are original designer for radiator stripper machine, so we can custom for your different radiator size, trust BSGH Granulator, help you gain more profits.

Patent and high-quality machines

As the inventor of the radiator recycling machine, we hold an exclusive patent and lead the industry with advanced craftsmanship and proven technology. Our machines deliver exceptional performance with minimal copper loss, achieving a 99.99% recovery rate. Built for durability, they ensure stable operation for over a decade under normal use.

Personalized customization service

Because of different radiators have many different size and shapes, so we support customizing copper tube center distance, motor brand, motor power, blade material, machine color, etc. to meet your special recycling needs.

Perfect after-sales service

We provide comprehensive perfect services to help you use the machine better. From equipment installation and operation training to daily maintenance, we have detailed instructions and provide online guidance. In addition, we provide 1 year warranty and lifetime online quick response service.

Global Market Inspection

Our radiator recycling machines have been exported to more than 80 countries including the United States, the United Kingdom, Italy, Japan, Thailand, etc., and have won unanimous praise from customers all over the world. You can feel confident in your decision to partner with us, and we will do our best to provide you with the best machines and services.

welcome to our factory