100T TIN Aluminum ubc can baling machine

100T UBC Can Bailing Machine is a compact pressure baler machine optimized for efficiently compressing used beverage cans(UBC). This versatile machine can process various types of aluminum cans and light metal materials, including aluminum foils, assembled with famous spare parts, ensuring the best performance and long life span.

Professional – Multifunction – Durable

100T TIN/Aluminum ubc can baling machine

Standard Configuration:

- 1000KN

- 400*400 Bales

Optional:

- 300*300 Bales

- 500KN/800KN/1250KN/1350KN/1600KN

- Support Customized

How UBC can bailing machine works?

This is a machine inspection video running for our Chile customer. He purchased BS81T-1000 aluminum can baling machine and we are inspecting it right now. We can see the blue conveyor belt at the beginning of the video which is used to transport scrap aluminum cans into machine hopper, after cans enter into pressure box, under the joint action of three hydraulic systems, the cans will be packed into blocks . As you can see from the video, machine runs smoothly, with even speed and good stability and the hopper connected to it has a clean and tidy appearance which has a large capacity. The machine inspection process was smooth and successful indicating its good quality and efficiency.

Machine Advantages:

The aluminum UBC can baling machine from BSGH Granulator is fully equipped with conveyor belt and roller magnetic separator, assemble with famous hydraulic system, waste aluminum cans will be automatically sent to hopper by conveyor belt, automatic and high efficiency bailing operation, convenient for transport.

The magnetic separator is used to guarantee the purity of the final products. The powerful hydraulic system and stable performance make the packaged aluminum blocks strong in structure and uniform in size. Each packaged block has no missing parts, so they can be sold at a good price in the scrap metal recycling market helping you to make profits. The entire operation process of the machine is simple and easy to understand. There is no need to spend energy and money on employee training which saves time and training costs at same time.

- 1000KN pressure guarantees superior product quality, ensuring that the packaged aluminum blocks are of the highest standard, have high economic value.

- Fully automatic operation, no manpower required, saving costs.

- All parts are made of national standard materials with high quality and good durability.

Machine technical datas:

No. | Technical Parameter | Remarks | ||||||

1 | Main Cylinder | Model | YG220/160-1210 | 1 | ||||

|

| Nominal Force | 1000KN | Stroke | 1210MM |

| ||

2 | Side Cylinder | Model | YG220/160-1740 | 1 | ||||

|

| Nominal Force | 1000KN | Stroke | 1740MM |

| ||

3 | Small Door Cylinder | Model | YG100/65-500 | 1 | ||||

|

| Nominal Force | 200KN | Stroke | 500MM |

| ||

4 | Pressure Box Size(L*W*H)(mm) | 1500*800*400 |

| |||||

5 | Bale Size(W*H) (mm) | 400*400 |

| |||||

6 | Bale Weight(kg) | 30-35kg |

| |||||

7 | Hopper (L*W*H) (mm) | 2200*1200*1500 |

| |||||

8 | Working pressure(Mpa) | 20Mpa |

| |||||

9 | Cycle Length | ≥40S |

| |||||

10 | Motor | Model | Y225S-4 | Nominal Power | 37KW |

| ||

|

| Nominal Speed | 1480r/min | Quantity | 1 set |

| ||

11 | Oil Pump | Model | HY180Y-RP | Nominal Pressure | 31.5Mpa |

| ||

|

| Nominal Outflow | 180ml/r | Quantity | 1 set | |||

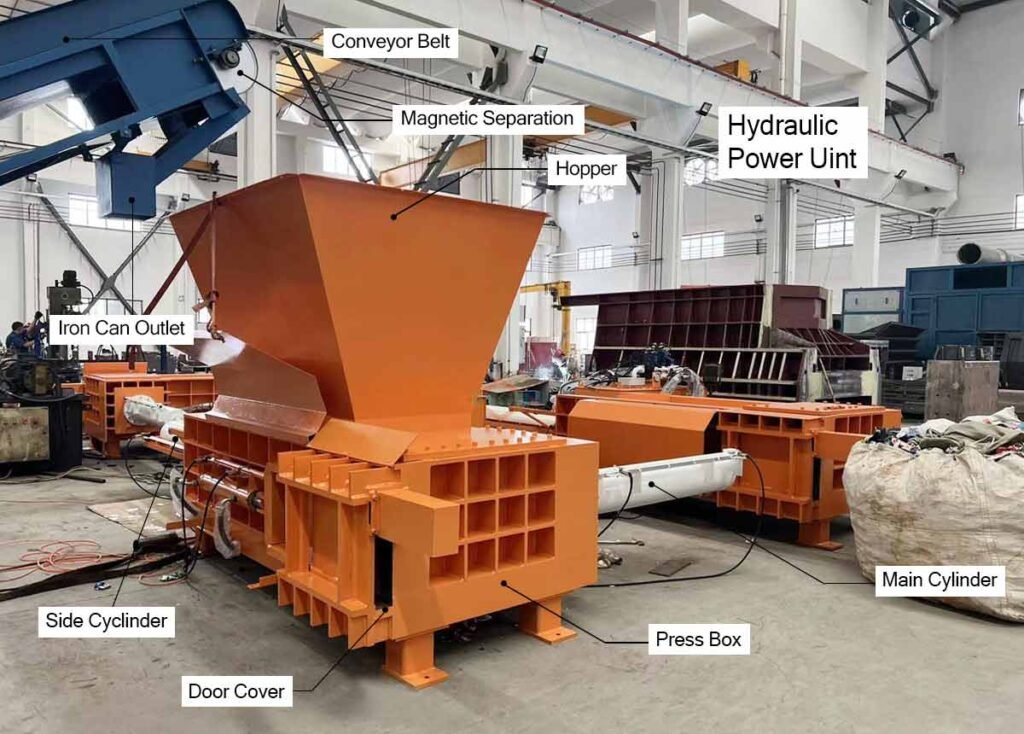

The structure of UBC can bailing machine Show:

Hopper: Hopper, the feeding part, has an inverted trapezoidal structure with a larger top and a smaller bottom allowing waste aluminum cans to enter the hydraulic tank smoothly.

Hydraulic power unit: The hydraulic power system has strong pressure and full power. The 3 hydraulic cylinders work together to pack aluminum cans making the entire packaging process easy and smooth.

Magnetic separator: This machine is also equipped with a magnetic separator, which ensures the purity of the final product, adsorbing iron cans mixed in the aluminum cans.

Raw Materials and final products:

Aluminum cans can be found everywhere. Many of the drinks are made from aluminum cans. The silver metal in the packaging of milk cartons we usually drink is aluminum. Aluminum metal can also be seen in chocolate packaging, western medicine packaging, etc. Surprisingly, the used aluminum cans still have a huge utilization value. Because of this, we invented the aluminum can baler machine to help people recycling waste aluminium. Each aluminum block packed by the BSGH Granulator aluminum can baling machine is uniform in weight and size and has a compact structure making it easy to transport and smelt.

There are many kinds of cans, used beverage cans, and various applications in different areas. This machine is mainly for aluminum cans, not fit for metal cans and hallow cans inner with pressure.

The aluminum UBC can bailing machine is mainly composed of two parts: the electrical system and the hydraulic power unit or conveyor belt with roller magnetic separator. The machine is simple, elegant and powerful.

Shipment:

We pursue both efficiency and quality in our work, so once the order is confirmed, we will immediately contact the production department to produce the machine. Each machine ready for shipment will be inspected repeatedly to ensure that it can operate normally. When the above process is confirmed to be correct, we will arrange the shipment, which will be transported by a reputable shipping company that we have cooperated with all year round.

our happy Customer from all over the world:

We have been in this industry for over 25 years. Many customers around the world have purchased aluminum can baler machines from us. They are very satisfied with our aluminum UBC can baling machine and have left positive reviews happily.

About Us

The world today consumes a large amount of metal every year. In Because of international call for environmental protection and the reality of economic development and transformation, the trend of scrap metal recycling is unstoppable. 25 years ago, we recognize the potential and prospects of metal recycling, so we strive to be an innovation and leader in this field. We are committed to developing advanced recycling technologies, and contributing our effort to the the environment protection.

Our products have gained high praise both at home and abroad thanks to their quality, efficiency, and considerate services. Modesty, conscientiousness, innovation, and perseverance form the core of our values. Moving forward, we will persist in our commitment to improvement and innovation to deliver even better products.

welcome to our factory

CE certificate

our ifat fair and canton fair

2 times offline exhibitions IFAT fair and 2 times offline exhibitions Canton fair