100~200KG/H Copper Granulator for Separate Copper and Plastic - Factory price

Copper granulator machines from BSGH Granulator have many types, 20~40KG/H(smallest), 40~60KG/H(single phase), 70KG/H(smallest 3phase granulator), 100KG/H, 200KG/H, 300KG/H; 300~500KG/H, 400~600KG/H, 1T/H, 1.2T/H, 1.5T/H and 2T/H.

100~200KG/H Copper Granulator for Separate Copper and Plastic

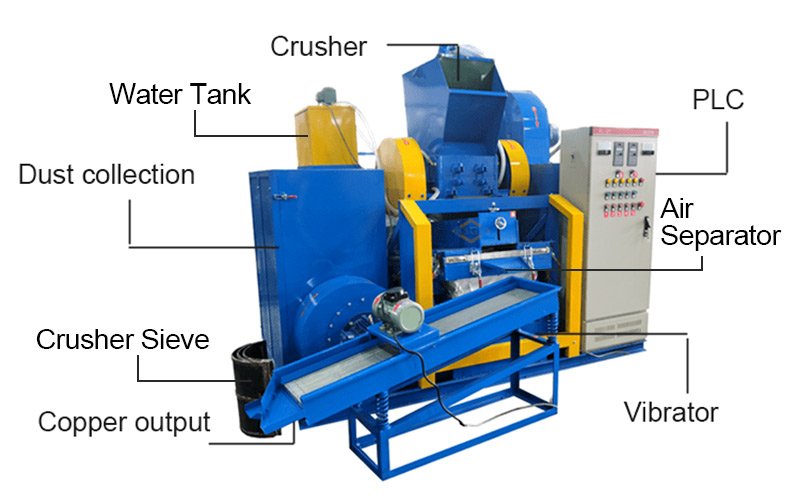

100~200KG/H copper granulator machine belongs to small granulators, it’s one integrated type, consisting of an air gravity separator, crusher, dust collection system, 2 small table vibrators, this is all necessary parts; also optional parts: conveyor belt, magnetic separator, electrostatic separator, dual shaft shredder and so on.

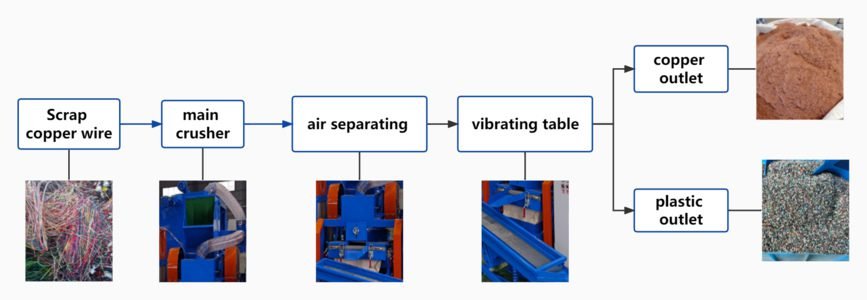

how does a copper granulator work?

Copper granulator works by shredding and crushing scrap cable material into small pieces, through an air separator system and small table vibrator separating to get the pure copper and plastic.

Products features:

The BS-D10/D20 wire copper granulator is a high-performance machine renowned for its ability to efficiently process various types of wires, operating at a speed of 100 to 200 kilograms per hour. This includes automotive woven wires, car wiring harnesses, communication wires, and more kinds. Its compact size and user-friendly operation make it ideal for overcoming space and labor constraints particularly popular in small copper recycling centers and scrap yards.

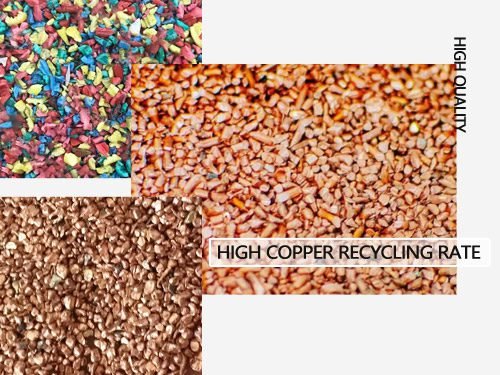

Utilizing cutting-edge production technology developed by BSGH, our wire copper granulator boasts enhanced performance capabilities. It excels in the separation of purer copper from mixed material, thereby increasing the overall value of the output. This makes it a preferred choice for businesses seeking to maximize their efficiency and profitability in the copper recycling industry.

- Complete functions with a relatively cheap price

- Compact size and easy-to-operate interface

- Pure final copper with 99.99%, high efficiency

- The dust collection box is a common industrial equipment that can effectively collect and filter dust and particles in the air, making the air cleaner and healthier, and reducing the number of times to clean the air flow separation net. Depending on the application, we will equip it Different bag numbers; you can also choose pulse dust removal, so that the machine can automatically clean the dust, which is more convenient and efficient.

- Our technical team has meticulously designed every aspect of the airflow separation system, from materials to tilt angle and eccentric axis. With best materials and precise engineering, we’ve ensured optimal performance, durability, and efficiency. The tilt angle and eccentric axis have been fine-tuned for maximum effectiveness and minimal energy consumption. Our dedication to innovation ensures our system remains at the forefront of technology differs with other machine.

- Wide processing diameter under 25MM, for above 25MM diameter, we recommend use wire stripping machine to process first.

Service support:

- 1year warranty

- Life-long service support and spare parts support

- On site technical support

- 99.99% recycling rate

- Durable and cost-effective: more than 10 years life

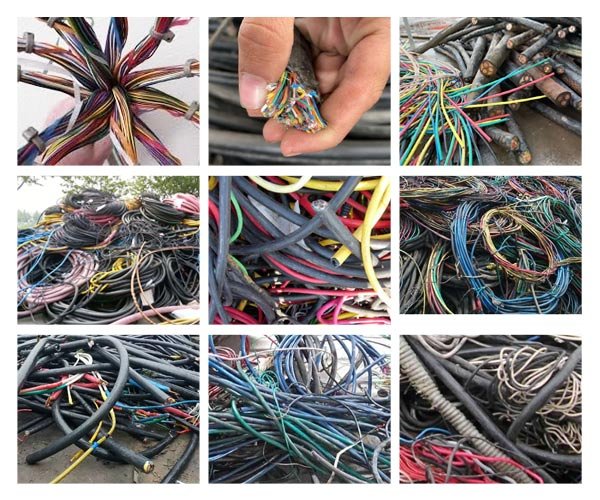

Raw Materials:

Our copper granulator machine can recycle all kinds of scrap cables: car cables, telecommunication cables, power cables, slim cables, flat wire, hair wire and etc.

technical datas:

| Model | BS-D10 | BS-D20 |

|---|---|---|

| Weight | 1800KG | 2000KG |

| Motor Power | 24KW | 28KW |

| Capacity | 100KG/H | 200KG/H |

| Motor Voltage | 380V/440V/480V or Customized | |

| Machine Size(L*W*H) | 2690*2020*2260MM | 2710*1980*2200MM |

Main Structure:

- Main Crusher: The main part of the copper granulator machine. We use high-hardness blades, which can easily and efficiently crush waste cables. Compared with ordinary blades, they are more wear-resistant.

- Air Separator: The principle of the air separator is metal and plastic have different densities, if these two things meet the airflow, they will be separated and move to different outlets. The speed and angle of the wind will affect the separation effect.

- Vibrating Table: The vibrating table always cooperates with the air separator, both in copper outlet and plastic outlet. They both contribute to separating copper and plastic. The frequency of the vibrating table will affect the separation.

Working Process:

The whole process can be divided into three steps:

- Step one: Put the scrap copper wires into the feeding part. Blades in the crusher will crush the scrap copper wire into smaller pieces.

- Step two: The crushed copper wire pieces are transported to an air separator which separates copper from plastic.

- Step three: The waste cable particles are further processed on a small vibrating table which provides double protection for copper separation.

- Finally, you will get copper granules with high purity.

Final Products:

End copper and plastic.

Shipment:

These 2 models are ship with LCL, machine will packed with plastic foam first, after packed with plywood case, then loading to container, but many of models will loading with FCL.

Customer from all over the world:

About Us

In more than 25-year development of the BSGH series of copper granulator machines. New products have been continuously added according to market demand, so whether it is a large enterprise or a small household, you can find what you need here. Each machine is developed through discussion and research by the technical team and market analysis team and they also be continuously upgraded and modified based on feedback from customers around the world. Therefore, the technology of these machines is mature and the performance is stable. BSGH Granulator machines are trustworthy, deserve you choose!

welcome to our factory