Industrial motor stator recycling plant

- From the world’s most professional motor stator recycling plant manufacturer – BSGH Granulator.

- An efficient, fully automated motor stator recycling solution with multi-stage shreddering and fine separating process.

- Recovery rate up to 99.9% & 100% pure metal final products, quickly creating higher returns.

What is motor stator recycling plant?

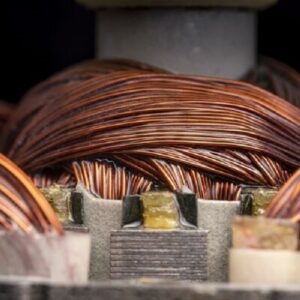

The Motor Stator Recycling Plant is an innovative solution specifically engineered for recycling scrap motor stators and turns scrap motor stators into high-value resources. After the casing is removed, the system uses an advanced combination of shredding, crushing, and multi-stage separation—including magnetic, air, and vibrating separation—to extract high-purity copper, iron, and plastics automatically. These separated materials are ready for direct sale in the market at premium prices, ensuring both high recovery rates and maximum economic value.

BSGH Granulator electric motor stator recycling plant

Our motor stator recycling plant is ideal for processing all types of common small motor stators, such as those used in household appliances, automotive, and industrial motors. Through precise sorting, it maintains 100% copper purity, directly improving your profitability.

- Capable of processing up to 2.2 tons of stators per hour, you can run electric motor recycling line smoothly and continuously.

- It’s built to handle all kinds of small motor stators (50–250 mm in diameter) with precision and ease.

- With an impressive 99.9% recovery rate, you capture almost every bit of valuable copper, iron, and plastic—turning waste into high-value revenue.

- If your scrap motors haven’t remove the housing, you can use our Electric Motor Stator Cutting Machine to remove the casing before feeding the stator into the production line.

Your reliable electric motor stator recycling plant for sale

Turn waste into profit with our Motor Stator Recycling Plant—a next-generation system that shreds, separates, and refines scrap stators into clean, high-value metals.

Delivering 99.9% recovery efficiency, it ensures every gram of copper and iron is recycled and ready for sale at top market prices, make your business competitive at the market.

While our motor stator recycling systems vary in configuration to meet different processing needs, If you have other requirements, feel free to contact us — our team will help you find or customize the solution that best fits your operation.

BSP-200 motor stator recycling plant

Crusher + Shredder + Magnetic separator + Air separation system + Vibrating table + Dust collection system

BSP-300 motor stator recycling plant

Hammer mill + Magnetic separator + Eddy current separator + Copper Granulator + Air separation + Vibrating table + Dust collection system

Working video of the motor stator recycling plant

Witness our motor stator recycling plant working in action. You can clearly see complete motor stators entering our recycle line via a conveyor belt and being efficiently crushed then sorted into pure copper, iron, and plastic. The entire process runs smoothly and continuously, with a clearly visible separation effect. Because of stable operation and excellent processing performance, the shredding and separating system is a reliable choice for achieving efficient metal recovery and maximizing value.

Structure and functions of electric motor stator recycling plant

Our motor stator recycling plant consists of core components such as a pre-shredder, main crusher, magnetic separator, air separator, and vibrating tables. Each component is optimally designed and works together to ensure efficient and high-purity recycling.

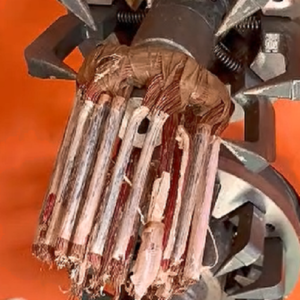

After the waste motor stators enter the machine via the conveyor, the pre-shredder uses low-speed, high-torque shearing to tear them into smaller pieces.

It crushes pre-shredded stators again, producing finer, more easily separable mixed particles.

• The blades are heat-treated for superior hardness and wear resistance. They maintain stable cutting performance and long service life, even when processing tough materials.

• You can flexibly control the final particle size by replacing the screens of different sizes.

Our machine is equipped with magnetic separators, which can separate and recover almost all iron, ensuring the iron inside is completely separated.

This part uses the principle of different weights about copper and plastic to separate them by wind power.

The vibrating table can perform secondary separation on the copper and plastic particles, ensuring the final copper recovery rate reaches 99.9% and does not contain any impurities.

The entire line adopts a PLC control system, achieving fully automated operation from feeding to discharging. This greatly reduces the technical requirements and labor costs for operators, and 1-2 people can easily complete the entire process.

High-efficiency pulse dust removal equipment will collect all dust generated throughout the entire process, ensuring a clean working environment and achieve a dust-free operation.

Raw material and End Product

Our advanced motor stator recycling plant is innovated to perfectly transform entire scrap stators into 100% clean copper, iron and plastic fragments you can resell at a high price. Please check the transformation below.

motor stator recycling plant application by types

Our comprehensive motor stator recycling plant is bulit for maximum versatility, capable of processing a wide range of scrap stator types covering from standard to specialized waste stators. To show you their unique shapes and complex internal structures our machine can processing, next we will present a detailed visual guide, demonstrating the adaptability of our motor stator recycling scope.

Common Motor Stator

- Application: Generally used in industry, the most common and basic stator type.

- Structure: Made of silicon steel sheets with a regular slot pattern, and the windings typically use enameled copper wire.

New Energy Motor Stator

- Application: Drive motors for electric and hybrid vehicles.

- Structure: The EV motor stator is made of ultra-thin, low-loss silicon steel sheets to reduce iron losses.

- Application: Hub motors for electric bicycles and electric scooters.

- Structure: Appears to be a flat disc with a large diameter, the stator core has multiple concentrated windings.

- Application: Starting the vehicle engine and providing initial torque.

- Structure: The permanent magnet type of car starter motor stator looks simple, compact, and highly efficient.

- Application: Household and industrial ceiling fans.

- Structure: The stator has a flat, disc-shaped looke to reduce overall height, its core is made of larger silicon steel sheets.

- Application: car charging systems generate electricity while the engine is running.

- Structure: The windings are typically wound with thick, enameled rectangular copper wire to improve current output and reliability.

- Application: Widely used in refrigerators, air conditioners, and other applications.

- Structure: Extremely compact to maximize internal space in the compressor. The vertical design directly matches to the its crankshaft.

Why Choose us?

As a leading global manufacturer of motor stator recycling equipment, BSGH Granulator not only provides powerful and stable motor stator recycling plant, but also makes your recycling production more efficient and worry-free with targeted solutions, global service support, and transparent and compliant cooperation processes.

30 years of rich experience

With over 30 years of experience in waste motor recycling, BSGH Granulator offers market-proven, continuously optimized machines that provide you with high efficiency and excellent material purity. We also provide customized solutions cater to your specific materials and production needs.

Sales footprint all over the world

Our motor stator recycling plant has been successfully exported to over 30 countries and regions, including Europe, America, Southeast Asia, and the Middle East. In numerous customer comparison tests, our machine has earned widespread trust from global customers for its excellent sorting performance and extremely low failure rate.

Transparent and Efficient Cooperation Process

After discussing the machine details, our sales will prepare a PI for you. You can bring it to your local bank to pay, ensure the security of your funds. Furthermore, we respect and strictly protect your business privacy, keeping all transaction details and your personal information completely confidential.

One-Stop Service

From purchase to operation, we provide comprehensive, one-stop service. From pre-sales one-on-one model recommendations, free machine placement planning, and circuit design, to after-sales installation guidance, operator training, a one-year warranty, and 24-hour rapid response, we help you easily resolve all machine-related issues.

CE certificated

All our motor stator recycling plants have already passed CE certification, so you can rest assured to importing.

Working video of electric motor stator recycling plant

Witness our electric motor scraping machine in action from the video below. To see more detailed photos, specifications, or even a live demonstration, please do not hesitate to contact us. We’re happy to provide you with all the information you need.

FAQ

Our main concern is ROI. How long can your motor stator recycling plant pay back?

In general, the payback period is between half month to one month, depending on your volume of raw materials and your operational costs.

We are not sure which motor stator recycling plant is right for us—BSP-200 or BSP-300?

The choice depends on your specific goals:

BSP-200: Our most popular stator recycling machine, if your motor shell already removed, then you can choose BS-P200.

BSP-300: Includes an Eddy Current Separator and Copper Granulator, if you want to recycle scrap motors with shell, then you can choose this bigger and more complete configuration model.

What if the stators we receive still have the outer housing?

Do not worry and there are two ways to solve your problem:

- You can use a Motor Shell Cutting Machine to remove the casing first then use the motor stator recycling line.

- We also offer scrap motors with shells recycling system to directly meet your needs.

Have any discount for this motor stator recycling plant?

You will receive a fixed price about our motor stator recycling plant. However, if you order multiple units, we are pleased to offer discounts.

Can your motor stator recycling plant fit my 600V 3 phase electricity?

Of course, your electricity is more preferable for our motor stator recycling plant, more stable.

what is the suggested amperage/breaker size for this motor stator recycling plant?

The normal working current for the motor stator recycling plant is 120~130A, but when the impact for motor stators is between 200~300A, its circuit breaker will reach to 400A, thus, you'd better buy a much bigger circuit breaker.

I still have some scrap cables, can your motor stator recycling plant handle them?

Yes, it can handle your cable after checking the picture, but please notice:

- Remove the first pre-shredder to keep the copper complete

- The cable below 50MM in diameter is best, if bigger size, you need buy more blades for longer use

discover More motor recycling solutions from us

BSGH Granulator provides a complete range of scrap motor recycling machines, from waste whole motors of various sizes and types to stators and rotors such as compressors, transformers, automotive generators, car starters, etc., we all have targeted professional recycling machines for your reference.

If you need to process a large number of rotors while recycling stators, our motor stator and rotor recycling line will be your best choice.

If your motors come with housings and you don’t want to remove them one by one, our whole motor recycling machine is optimal.

If you have a small number of motors or motors with a larger diameter, our electric motor wreckers can also recycle them efficiently.