MS-D1400 is an industrial dual-shaft shredder with excellent material adaptability. It continuously shears, tears, and squeezes the materials in the shredding chamber through the interaction of two main shafts rotating in opposite directions at high speed and multiple blades installed on the main shafts, and finally achieves sufficient shredding, providing a cost-efficient option for processing various waste materials. Whether it is high-hardness metal materials such as steel plates and iron pipes, or softer plastics, rubber, and wood, our MS-D1400 industrial metal shredder can easily and effectively reduce their size.

In July 2024, a Japanese customer imported a MS-D1400 industrial metal shredder from BSGH Granulator. The following is the feedback video he took after receiving the machine.

After receiving the machine, the customer shared his experience with us. He mainly used our shredder machine to process scrap steel plates. He was impressed by the performance, as the shredding effect far exceeded his expectations. During the shredding process, the machine always maintained excellent stability, ensuring continuous processing without interruption. Low noise and less dust ensured a comfortable working environment. In addition, he also said that what he was most satisfied with the MS-D1400 shredder machine was its shredding performance, which could easily shred the customer’s hard metal materials with minimal risk of getting stuck. After using our machine, the production efficiency of this Japanese customer has been greatly improved.

Model | MS-D1400 Industrial Metal Shredder |

Motor | 75KW (2) |

Reducer | ZSY400 (2) |

Blade Size | 550*50MM (28) |

Feeding Inlet | 1600*850MM |

Spindle | 42CrMo (2) |

Bearing | HLB spherical roller bearings |

Machine Size | 4800*1880*2300 |

MS-D1400 industrial metal shredder is equipped with two 75kw motors(we also support customization) and two reducers, achieving low speed and high torque, and can easily complete continuous high-intensity crushing tasks.

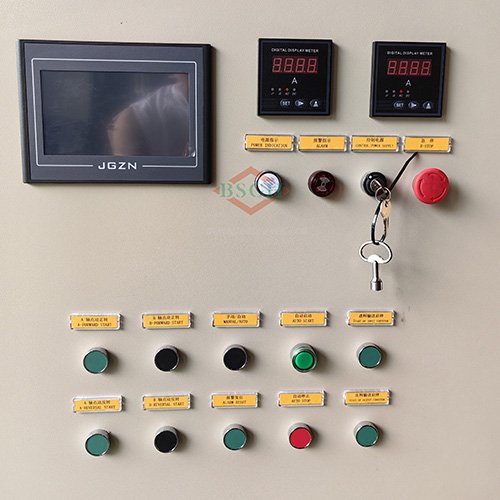

The machine is controlled by a PLC system, and it is easy to operate. Operators can control the machine proficiently without additional training. The machine can be easily started and stopped by simply pressing the button on the electric cabinet.

The shredder uses high-strength steel as its frame, which has good stability and can effectively resist vibration and impact during operation, ensuring long-term stable operation and extending its service life.

Our shredder machine has a reasonable overall layout, which saves space as much as possible, and the connections between various components are compact and easy to maintain. For example, we use patented bearing seats that are easy to disassemble, fully considering the convenience and reliability in actual use, making it more convenient for operators to maintain the machine daily.

Our MS-D1400 metal shredder perfectly combines reasonable price and excellent quality, providing you with the most cost-effective shredding solution, achieving both low cost and high profit. By choosing our equipment, you can earn back all machine costs within one month at the fastest and obtain long-term and stable profits.

MS-D1400 was loaded in 1*40″HQ.

Yes, our personalized customization service can meet almost all your machine requirements. Send your specific requirements to our staff, and we will create a perfect customized solution for you as soon as possible and quote you the best price. This machine also can config 2*90KW or 2*55KW motors.

Yes, we support FOB terms, you can haul the container to our factory or we can send to seaport for you. We generally recommend that we ship the machines, which can help you save money.

No. All the machines we send out are brand new and have undergone rigorous quality testing.

We provide a one-year warranty. Within the warranty period, as long as your machine is damaged by non-human factors, we can provide free repair or replacement.

Tks for your interesting for our machine, can you tell me more about your requests so i can recommend you the proper machine?

Online | Privacy policy

WhatsApp us

Which kinds of material you want to process?

Please fill in the following form(give us your specific requests, the detailed the better, so we can give you an optimal solution at the earliest time):

Maximize your recycling efficiency with our compact and powerful metal chip briquetting machines. Whether you’re dealing with small batches or large volumes of metal scrap, we have the perfect solution to fit your space and production needs.

Contact us today for a free, customized quote and discover how our briquette press can help you boost productivity and profits.

Ready to Turn End-of-Life Solar Panels into High-Value Treasure?

Whether you need a standalone Frame Dismantling Machine, a precision Glass Removal Machine, or a complete Solar Panel Recycling System—we have the right solution for your business.

Contact Us Today & Get a Free Quote tailored to your PV panels!

From robust tools to advanced recycling machinery, we provide a comprehensive selection: cutting, moving, shearing, grap, baler, separation, a series of heavy-duty equipment engineered to meet the demands of diverse industrial operations and material types. Which kinds of function do you need? Send us your requests now to let our machine help you to get more profits.

Please fill in the following form(tell us your requests or you can choose from):

| Home use wire stripper machine |

| 1.5MM-38MM; 2-45MM; 2-76MM; 2-60MM; |

| Industrial cable stripping machine |

| 10-120MM; 10-160MM; 60-200MM |

According to your requests, I’ll recommend the suitable machine.

We have all kinds of radiator recycling machines, besides single radiator stripper machines and radiator recycling lines, radiator cutting machines.

Our machines are capable of processing all kinds of scrap radiators, including car radiators, water tank radiators and AC radiators, aluminum-clad radiators etc.

Our metal baler can processing all types of scrap metals, besides light metal and heavy metals; ferrous metal and non-ferrous metals;

our machine have from small pressure to big pressure 80T, 125T, 135T, 160T, 200T, 250T,315T and 400T, if you not know which pressure should you choose, so please send us your material picture below and ask for a free quote now!

We have:

Can you tell me which kinds of material you want to process? click below and send material picture.

Process Motor Shell | Motor Stator | Motor Shaft

Motor Shell Cutting | Motor Stator Recycling

Auto Starter Cutting | Auto Starter Pressing | Car Starter Heating | Car Starter Pulling Machine

Car Alternator Cutting Machine | Car Alternator Pulling Machine

Motor Stator Recycling Line | Motor Rotor Recycling Line | Whole Motor Recycling Plant

For Small Transformer Recycling

Compressor Shell Cutting Machine | Compressor Stator Recycling

Mainly for Recycling Ceiling Fan Motors

For All Kinds of Car Magnetic Switch

For All Kinds of Electric Bike Hub Motors

Mainly for Press All Kinds of Motor Parts | Support Customized

1: Get copper price today FREELY!

2: Enter into scrap metal group FREELY!

3: Leave your information, get a cable cutter for FREE!

4: ROI Analysis for FREE!

5: Get extra one year warranty for FREE!

6: Get usd100 coupon for FREE!

7: Get spare parts for FREE!

8: Best seller of the month FREELY!

Note: Your email information will be kept strictly confidential.

Note: Your email information will be kept strictly confidential.

Please fill in the following form(tell us your requests or you can choose from):

| D Series Different Capacity |

| 50KG/H, 70KG/H, 100KG/H, 200KG/H, 300KG/H |

| N Series Different Capacity |

| 300~500KG/H, 400~600KG/H, 1T/H, 1200~1500KG/H |

According above different capacities, tell us your requests, once we get your detailed information for your requests, we will contact you at the first time with professional solutions and support from buying to using.